Application of a modified lignin nanocellulose film in triboelectric nanogenerators

A technology of nanocellulose and nanogenerators, applied in the direction of triboelectric generators, etc., can solve the problems of lack of biocompatibility and biodegradability, composite materials cannot be formed into films, etc., and achieve good biocompatibility and bioavailability Degradability, good electron absorbing/donating ability, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

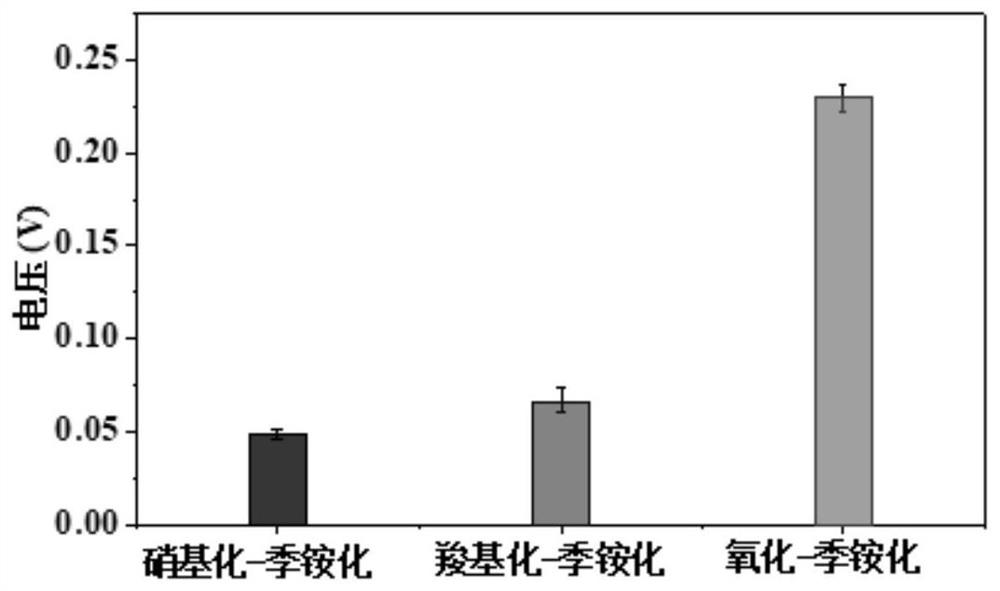

Embodiment 1

[0049] (1) According to the mass ratio of nanocellulose and modified lignin of 4:6, weigh quaternized lignin and nanocellulose with a feed ratio of 10% to prepare quaternized lignin nanofibers with a mass fraction of 0.75% 100% oxidized lignin and nanocellulose were weighed to prepare a mixed solution of oxidized lignin and nanocellulose with a mass fraction of 0.75%.

[0050] (2) Weigh 11.5 parts by mass of the quaternized lignin nanocellulose mixed solution and the oxidized lignin nanocellulose mixed solution and place them in a plastic petri dish with a diameter of 60 mm, air-dry naturally until the water evaporates completely, and peel off to obtain a thickness It is 22 micron quaternized lignin nanocellulose film and oxidized lignin nanocellulose film.

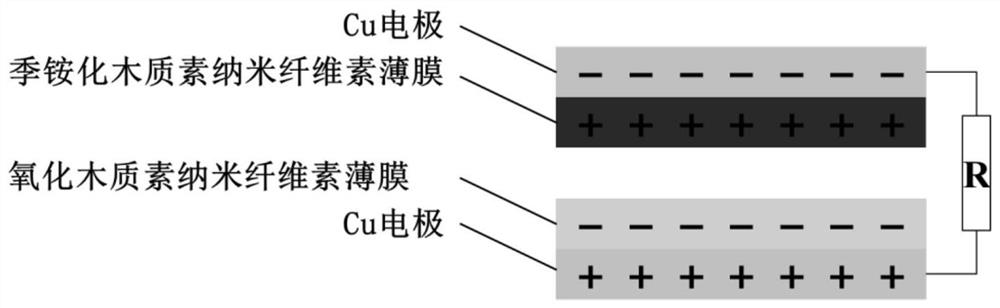

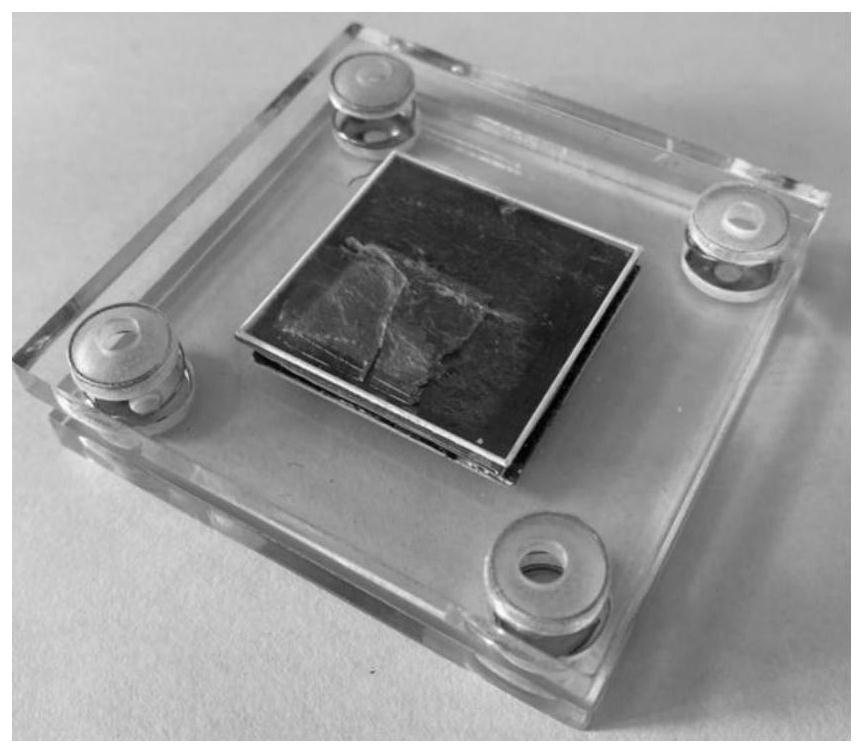

[0051] (3) Cut the obtained quaternized lignin nanocellulose film (positive electrode friction layer material) and oxidized lignin nanocellulose film (negative electrode friction layer material) into squares of 3 cm × 3 c...

Embodiment 2

[0053] (1) According to the mass ratio of nanocellulose and modified lignin of 4:6, weigh quaternized lignin and nanocellulose with a feed ratio of 25% to prepare quaternized lignin nanofibers with a mass fraction of 0.75% 100% oxidized lignin and nanocellulose were weighed to prepare a mixed solution of oxidized lignin and nanocellulose with a mass fraction of 0.75%.

[0054] (2) Weigh 11.5 parts by mass of the quaternized lignin nanocellulose mixed solution and the oxidized lignin nanocellulose mixed solution and place them in a plastic petri dish with a diameter of 60 mm, air-dry naturally until the water evaporates completely, and peel off to obtain a thickness It is 22 micron quaternized lignin nanocellulose film and oxidized lignin nanocellulose film.

[0055] (3) Cut the obtained quaternized lignin nanocellulose film (positive electrode friction layer material) and oxidized lignin nanocellulose film (negative electrode friction layer material) into a 3cm×3cm square and ...

Embodiment 3

[0057] (1) According to the mass ratio of nanocellulose and modified lignin 4:6, weigh the quaternary ammonium lignin and nanocellulose with a graft ratio of 50% to prepare a quaternary ammonium lignin with a mass fraction of 0.75% A mixed solution of cellulose and nanocellulose was weighed, and the material ratio of 100% oxidized lignin and nanocellulose was weighed to prepare a mixed solution of oxidized lignin and nanocellulose with a mass fraction of 0.75%.

[0058] (2) Weigh 11.5 parts by mass of the quaternized lignin nanocellulose mixed solution and the oxidized lignin nanocellulose mixed solution and place them in a plastic petri dish with a diameter of 60 mm, air-dry naturally until the water evaporates completely, and peel off to obtain a thickness It is 22 micron quaternized lignin nanocellulose film and oxidized lignin nanocellulose film.

[0059] (3) Cut the obtained quaternized lignin nanocellulose film (positive electrode friction layer material) and oxidized li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com