Processing method of broken walnut granules in granular walnut milk beverage

A processing method, walnut crushing technology, which is applied in the processing field of walnut crushed walnut milk beverages, can solve the problems of walnut milk taste and nutritional value adverse effects, easy oxidation, temperature sensitivity of antioxidant active ingredients, etc., to achieve relief Wastewater treatment burden, rinsing water saving, effect of maintaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

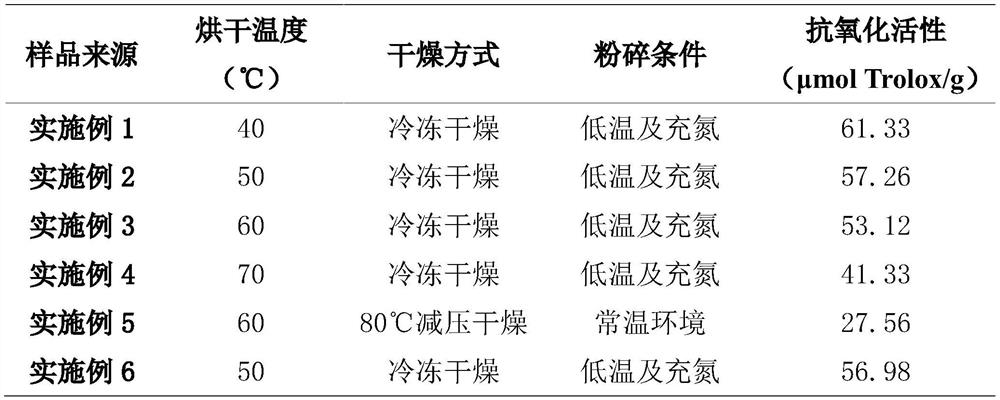

Examples

Embodiment 1

[0025] Prepare walnut crumbs as follows:

[0026] (1) Low-temperature drying: dry the walnut kernels from which the shell has been removed, and dry at a drying temperature of 40° C. for 6 hours;

[0027] (2) crushing: the above-mentioned walnut kernels after drying are crushed to obtain coarse broken walnut particles;

[0028] (3) Peeling by electrostatic method: Put the coarse walnut particles obtained in (2) into an electrostatic cylinder for peeling, and the shells with poor conductivity are sucked by the roller until they are brushed off; The drum falls ahead of time, and the coarse walnut kernel particles after peeling are collected.

[0029] (4) Freeze-drying: vacuum freeze-drying after pre-freezing in a refrigerator at -80°C, and drying until the moisture content reaches 6%;

[0030] (5) Pulverization: the freeze-dried walnut kernels are pulverized in a pulverizer, the above-mentioned coarse powder is placed in an ultrafine pulverization vibrating mill, and pulverized...

Embodiment 2

[0034] Prepare walnut milk as follows:

[0035] (1) Drying: Dry the walnut kernels from which the shell has been removed, and dry for 4 hours at a drying temperature of 50°C;

[0036] (2) crushing: the above-mentioned walnut kernels after drying are crushed to obtain coarse broken walnut particles;

[0037] (3) Peeling walnut kernels: put the coarse walnut particles obtained in (2) into an electrostatic cylinder for peeling, and the kernel skins with poor conductivity are sucked by the roller until they are brushed off; The drum falls ahead of time, and the coarse walnut kernel particles after peeling are collected.

[0038] (4) Freeze-drying: vacuum freeze-drying after pre-freezing in a refrigerator at -80°C, until the moisture is 5%;

[0039] (5) Pulverization: the freeze-dried walnut kernels are pulverized in a pulverizer, the above-mentioned coarse powder is placed in a vibrating mill for ultrafine pulverization, and pulverized for 1 min under low temperature and nitrogen ...

Embodiment 3

[0043] Prepare walnut crumbs as follows:

[0044] (1) Drying: Dry the walnut kernels from which the shell has been removed, and dry for 4 hours at a drying temperature of 50°C;

[0045] (2) crushing: the above-mentioned walnut kernels after drying are crushed to obtain coarse broken walnut particles;

[0046] (3) Peeling walnut kernels: put the coarse walnut particles obtained in (2) into an electrostatic cylinder for peeling, and the kernel skins with poor conductivity are sucked by the roller until they are brushed off; The drum falls ahead of time, and the coarse walnut kernel particles after peeling are collected.

[0047] (4) Freeze-drying: vacuum freeze-drying after pre-freezing in a refrigerator at -80°C, until the moisture is 5%;

[0048] (5) Pulverization: the freeze-dried walnut kernels are pulverized in a pulverizer, the above-mentioned coarse powder is placed in a vibrating mill for ultrafine pulverization, and pulverized for 1 min under low temperature and nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com