Reduced coenzyme and analogue regeneration catalyst as well as preparation method and application thereof

A regenerated catalyst and reduced technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical recovery, etc., can solve the problems of easily interfering with enzyme-catalyzed reactions and high prices, and achieve high activity, low preparation cost, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] Preparation of Regenerated Catalysts for Reduced Coenzyme and Its Analogs

[0094] The metal sulfide catalyst involved in the present invention is deposited on a certain substrate by an electrochemical method as a working electrode for electrocatalytic or photocatalytic NAD(P)H reduction regeneration, wherein electrochemically deposited cobalt molybdenum sulfur, cobalt tungsten sulfur, nickel sulfide The precursors of metal sulfides such as molybdenum sulfide and molybdenum sulfide are [Co(MoS 4 ) 2 ] 2- 、[Co(WS 4 ) 2 ] 2- 、NiCl 2 + Thiourea mixture, (MoS 4 ) 2-Solution, taking the deposition of cobalt molybdenum sulfur catalyst on the foamed copper substrate as an example, the specific steps are as follows:

[0095] Cu / CoMoS x Electrode preparation

[0096] Cut the copper foam used as the electrode base into a certain shape (such as a rectangle), cover one side with epoxy resin and seal and expose a certain area on the other side. Before starting to deposit ...

Embodiment 1

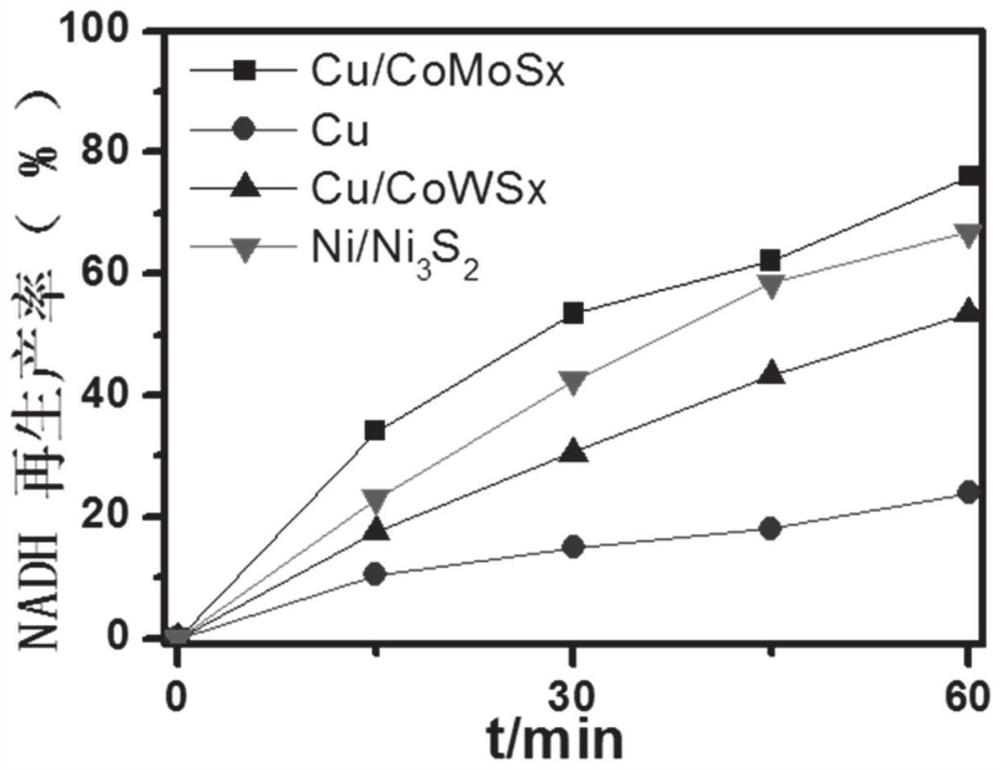

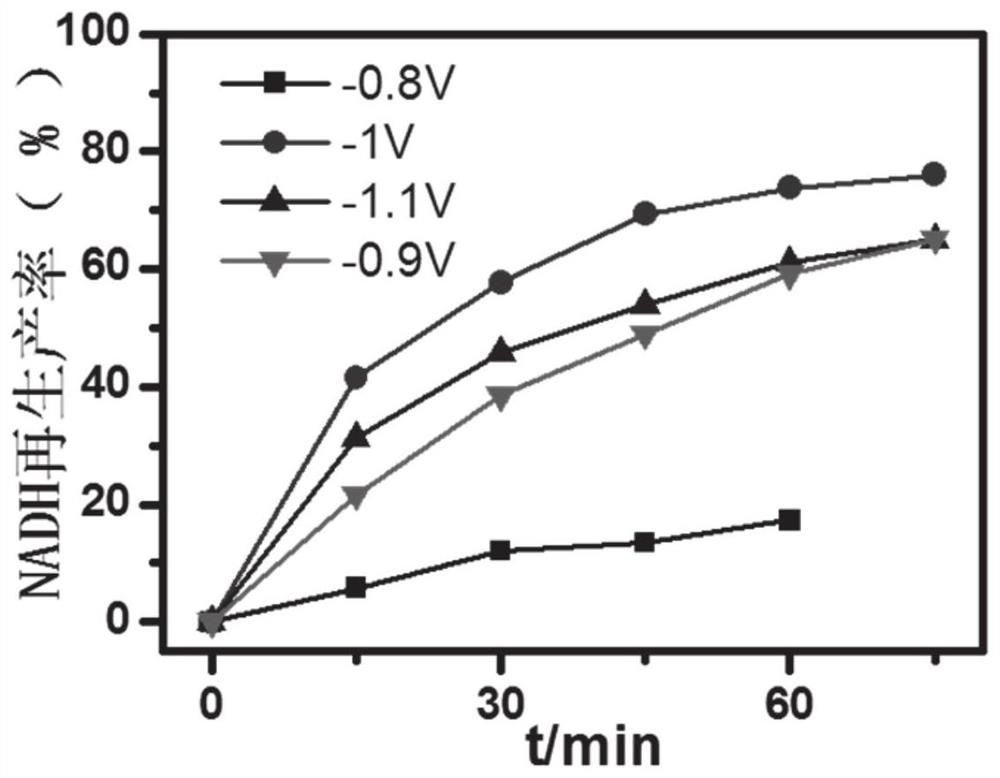

[0100] Example 1 Different metal sulfide catalysts electrocatalyze NAD + Reduction and regeneration of NADH.

[0101] At 25°C, in the presence of 0.5mM NAD + (sigma) in 0.1M sodium phosphate buffer solution (pH 7), with Cu / CoMoS x The electrode is the working electrode, the Ag / AgCl electrode is the reference electrode, and the platinum electrode is the counter electrode, and NAD is performed at -0.9V vs.Ag / AgCl + reduction reaction. During the reaction process, the flow rate of argon gas was 15ml min. -1 , extract 50 μl of the reaction solution every 15 minutes, dilute it 50 times, and measure the ultraviolet-visible absorption spectrum. According to the absorption peak of NADH at 340 nm, the concentration of NADH regeneration is calculated by Lambert-Beer's law.

[0102] CoWS x 、Ni 2 S 3 , and other metal sulfide catalysts can also be used in the NADH regeneration reaction. The measured NADH regeneration conversion rate is as follows: figure 1 shown, where CoMoS x Th...

Embodiment 2

[0103] Example 2 Electrocatalytic NAD under different pH + Reduction and regeneration of NADH.

[0104] Cu / CoMoS was prepared by the aforementioned method x electrodes, at 25°C, respectively, in 0.5mM NAD + In 0.1M sodium phosphate buffer solution with pH 5, 6, 7, 8, 9, Cu / CoMoS x The electrode is the working electrode, the Ag / AgCl electrode is the reference electrode, and the platinum electrode is the counter electrode, and NAD is performed at the potential of -0.9V vs.Ag / AgCl + During the reduction reaction, argon gas was introduced throughout the reaction process, and after 60 minutes of reaction, the absorbance value at 340nm was detected by ultraviolet-visible absorption spectroscopy, and the concentration of NADH regeneration was calculated by Lambert-Beer's law. NAD at different pH + The conversion ratios of reduction and regeneration of NADH are shown in Table 2:

[0105] Table 2. Cu / CoMoS at different pH x Electrocatalytic reduction of NAD + conversion rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com