Method for preparing super-hydrophobic radiation refrigeration material through in-situ extraction of silicon dioxide microspheres from rice hull ash and super-hydrophobic radiation refrigeration material

A technology of silicon dioxide and radiation refrigeration, applied in the direction of silicon dioxide, silicon oxide, heating to dry solid materials, etc., can solve the problems of large energy consumption, shedding, pollution, etc., to improve the performance of radiation refrigeration, and achieve good radiation refrigeration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

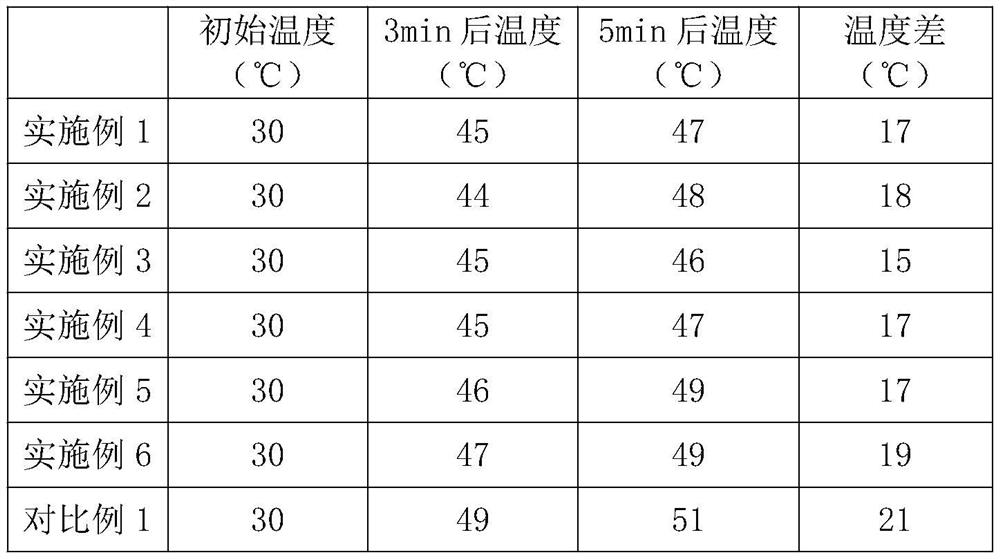

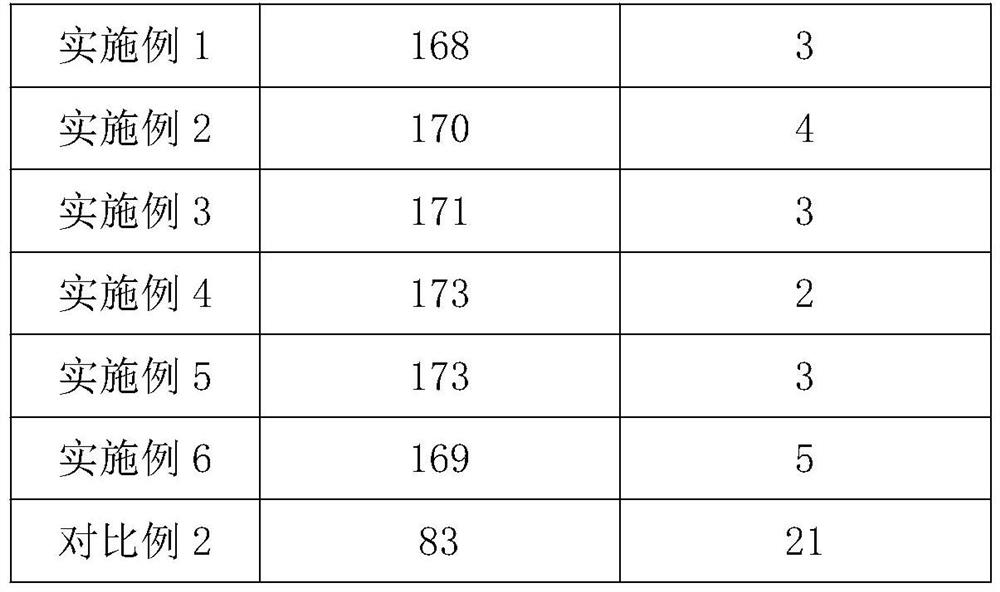

Embodiment 1

[0029] (1) Preparation of silica microspheres: After washing the rice husk with water, drying, pulverizing and sieving, adding hydrochloric acid with a concentration of 3%, the mass ratio of the rice husk to hydrochloric acid is 0.5:1, at 50°C Stir fully under water, wash with water until the pH value is neutral, and obtain rice husk ash after filtering and drying; get 30g of rice husk ash, mix evenly with 4wt% NaOH solution in a ratio of 1:5 according to the mass ratio, and heat to Reflux at 90°C for 2 hours, filter while it is hot, and transfer the filtrate to the carbonization tube; place the carbonization tube in a constant temperature device at 90°C, pass simulated lime kiln gas into the carbonization tube for carbonization reaction for 85 minutes, and lower the temperature to room temperature after carbonization Aging for 2 hours, filtering again, washing the filtered filter cake with water until the pH value is neutral, raising the temperature to 110°C and drying for 11 ...

Embodiment 2

[0033] (1) Preparation of silica microspheres: After washing the rice husk with water, drying, pulverizing and sieving, adding hydrochloric acid with a concentration of 5%, the mass ratio of the rice husk to hydrochloric acid is 0.55:1, at 52°C Stir fully under water, wash with water until the pH value is neutral, obtain rice husk ash after filtering and drying; get 32g of rice husk ash, mix evenly with 4wt% NaOH solution according to the mass ratio of 1:6, and heat to Reflux at 94°C for 2.2 hours, filter while it is hot, and transfer the filtrate to the carbonization tube; place the carbonization tube in a constant temperature device at 91°C, pass simulated lime kiln gas into the carbonization tube for carbonization reaction for 87 minutes, and lower the temperature to room temperature after carbonization Aging at low temperature for 2.4 hours, filtering again, washing the filtered filter cake with water until the pH value is neutral, raising the temperature to 114°C and dryin...

Embodiment 3

[0037] (1) Preparation of silica microspheres: After washing the rice husk with water, drying, pulverizing and sieving, adding hydrochloric acid with a concentration of 7%, the mass ratio of the rice husk to hydrochloric acid is 0.6:1, at 54°C Stir fully under water, wash with water until the pH value is neutral, obtain rice husk ash after filtering and drying; get 34g rice husk ash, mix evenly with 4wt% NaOH solution according to the ratio of 1:7 according to the mass ratio, and heat to Reflux at 98°C for 2.4 hours, filter while it is hot, and transfer the filtrate to the carbonization tube; place the carbonization tube in a constant temperature device at 92°C, pass simulated lime kiln gas into the carbonization tube for carbonization reaction for 89 minutes, and lower the temperature to room temperature after carbonization Aging at low temperature for 2.8 hours, filtering again, washing the filtered filter cake with water until the pH value is neutral, raising the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com