Light-weight high-strength calcium silicate board for coating/film covering and preparation method of light-weight high-strength calcium silicate board

A calcium silicate board, calcium silicate technology, applied in the field of building materials, can solve the problems of limiting the wide application of low-density calcium silicate board, lack of evaluation and improvement of bonding strength of lightweight boards, etc., to achieve high internal bonding strength, fireproof Excellent performance and high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

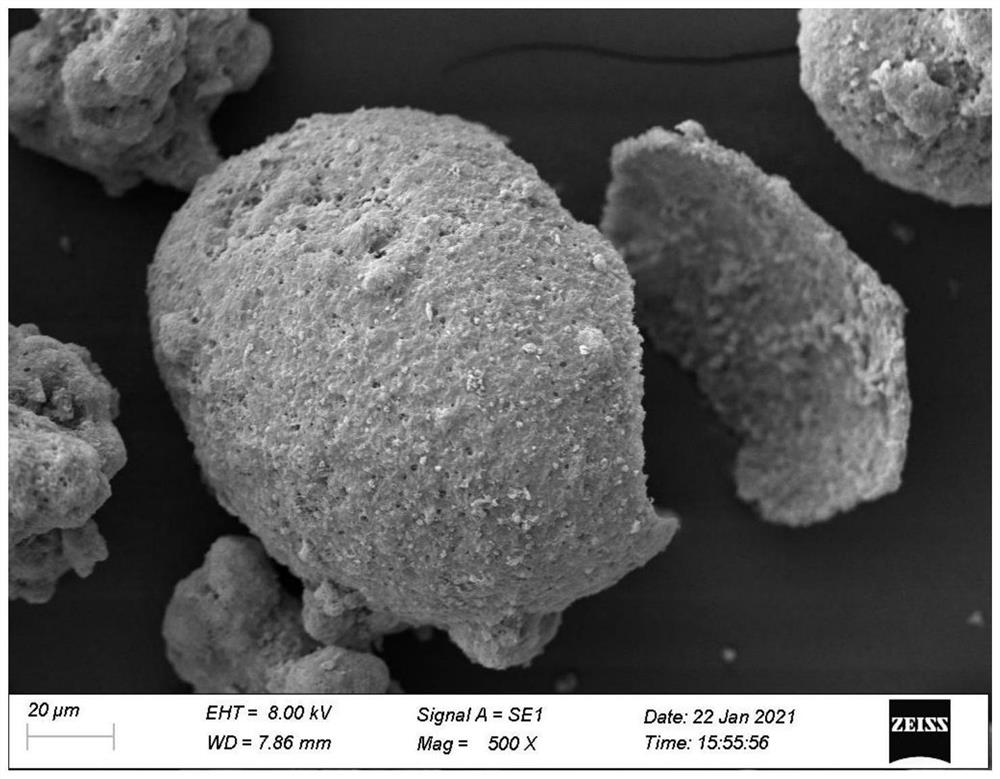

Embodiment 1

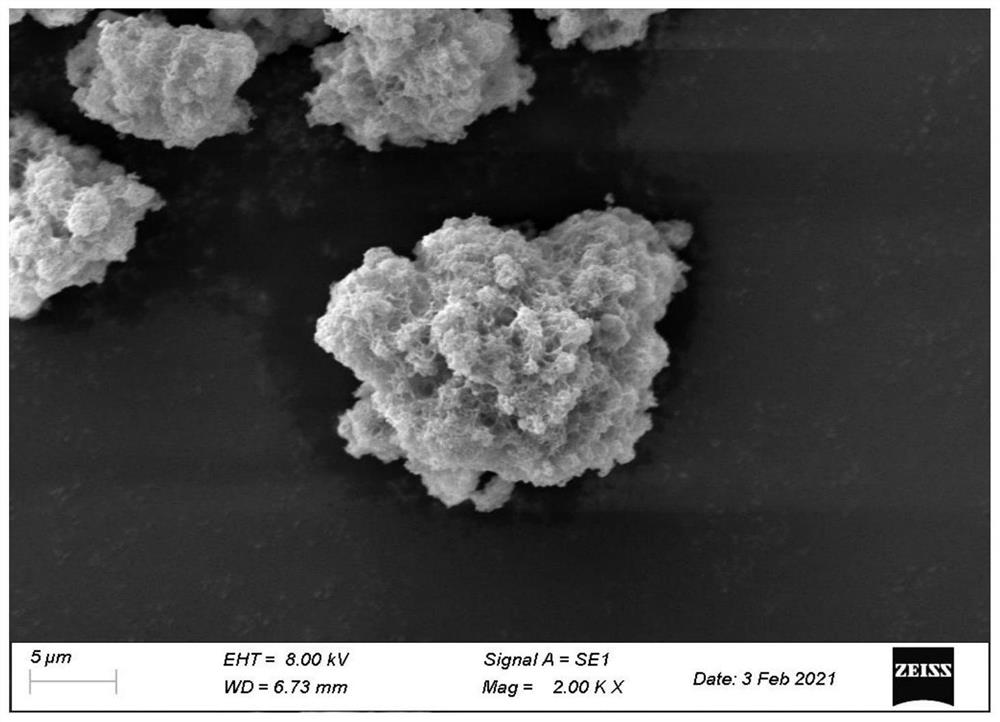

[0028] This embodiment provides a lightweight high-strength silicate plate, and the raw material component is percentage of weight, including: silica material quartz powder 24.5%, calcium material coating 26.4%, cement 19.7%, calcium silicate crystal, 25.5%, The fiber pulp is 7.6%, the inorganic packing silica grayite 3.3% and the plate inorganic aid bentonite 3%.

[0029] Among them, the preparation method of calcium silicate crystals includes the step of: mixing the silicon feedstock quartz powder and calcium raw material to mix lime by mass ratio 1: 1.2, and the mixture is prepared in a stirred reaction kettle, preparation temperature 185 ° C, After the preparation is complete;

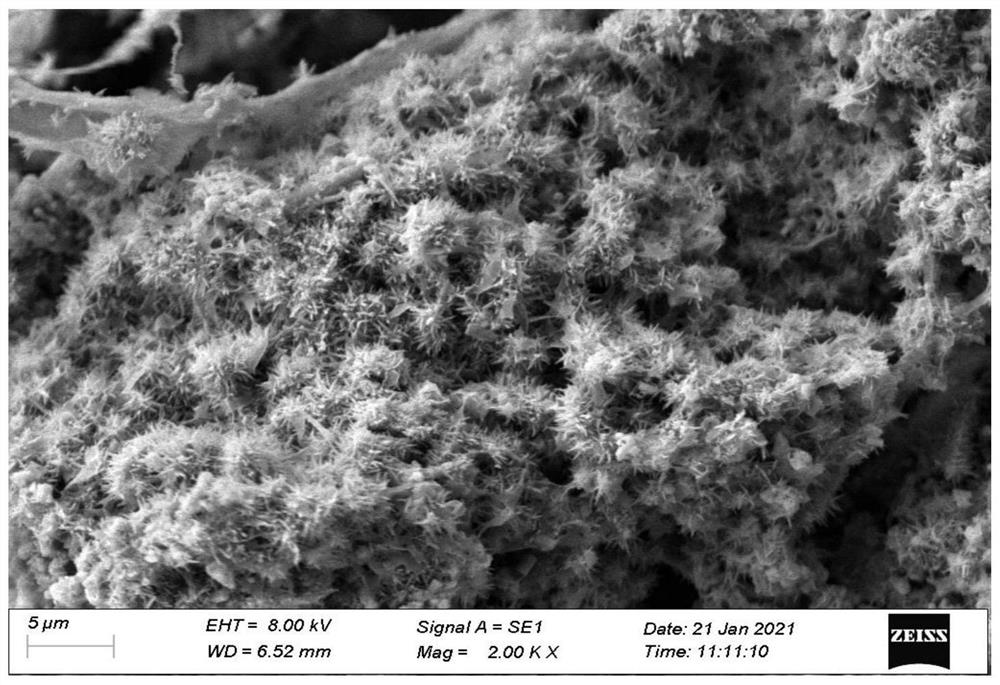

[0030] The method of preparation of the fiber slurry includes the steps: the fiber material pulp fibers are first broken in the pulper, and the fragmentation concentration of the fiber slurry is 5.5%, and then the grinding machine is performed by the abrasive machine, the grinding concentration is 4.2%...

Embodiment 2

[0037]This embodiment provides a lightweight high-strength silicate plate, and the raw material component is percentage of weight, including: silica material quartz powder 24.5%, calcium material coating 26.4%, cement 19.7%, calcium silicate crystal, 25.5%, The fiber pulp is 7.6%, the inorganic packing silica grayite 3.3% and the plate inorganic aid bentonite 3%.

[0038] Among them, the method of preparing the calcium silicate crystal comprises the step of: mixing the silicon raw material silica ash and calcium raw lime by mass ratio 1: 1, mixing material for 4h prefabrication in a stirred reaction kettle, preparation temperature 175 ° C, After the preparation is complete;

[0039] The method of preparation of the fiber slurry includes the steps: the fiber material pulp fibers are first broken in the pulper, and the fragmentation concentration of the fiber slurry is 5.5%, and then the grinding machine is performed by the abrasive machine, the grinding concentration is 4.2% to obt...

Embodiment 3

[0046] This embodiment provides a lightweight high-strength silicate plate, and the raw material component is percentage of weight, including: silica material powder 25.4%, calcium material coating 25.2%, cement 22.6%, calcium silicate crystals, 12.8%, The fiber pulp is 7.5%, the inorganic filler silica grain 3.5% and the plate-inorganic aid bentonite 3%.

[0047] Among them, the method of preparing the calcium silicate crystal comprises the step of mixing the silica raw material powder and calcium raw plascate is mixed by mass than 1: 1, and the mixture is prefabricated in a stirred reaction kettle, preparation temperature 180 ° C, After the preparation is complete;

[0048] The method of preparation of the fiber slurry includes the steps: the fiber material pulp fibers are first broken in the pulper, and the fragmentation concentration of the fiber slurry is 5.5%, and then the grinding machine is performed by the abrasive machine, the grinding concentration is 4.2% to obtain fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Internal binding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com