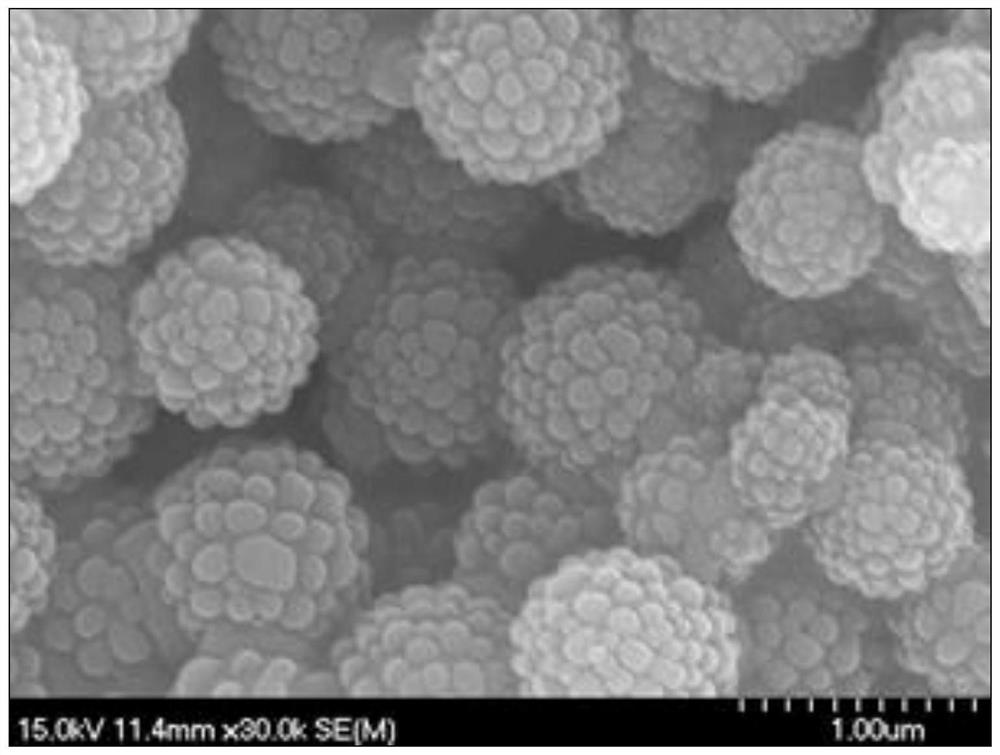

Preparation method of raspberry-shaped SiCxNyOz microspheres converted by polysilazane

A technology of polysilazane and raspberry, which is applied in the field of micron ceramic powder preparation, can solve the problems of complex preparation process and achieve the effects of simple preparation method, good loss and absorption, and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

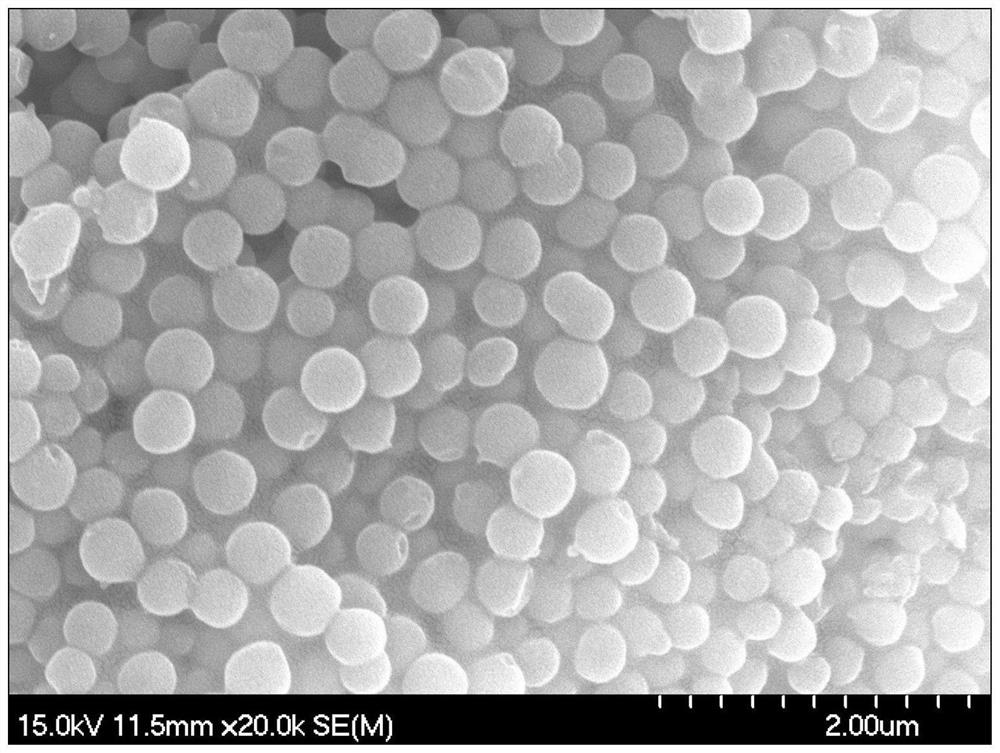

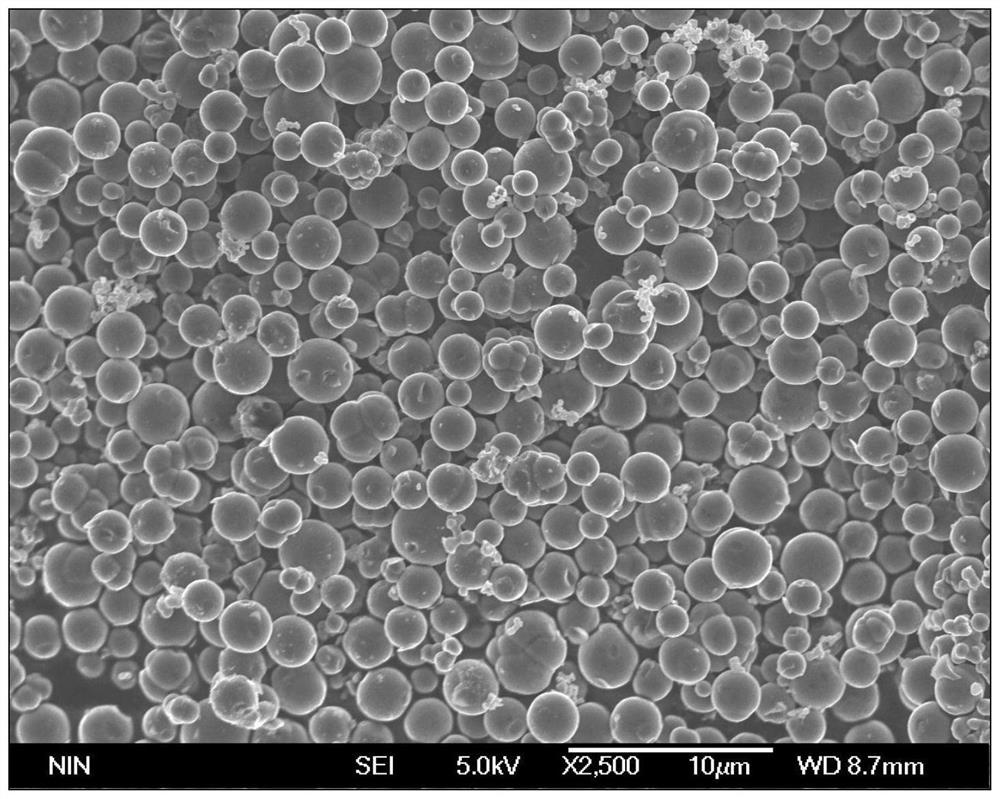

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

[0028]Step 1, preparing divinylbenzene, carbon-carbon double bond-containing polysilazane, 2,2'-azobisisobutyronitrile and acetonitrile into a mixed liquid; the quality of divinylbenzene in the mixed liquid is two 20% of the total mass of vinylbenzene and polysilazane containing carbon-carbon double bonds, the mass of the 2,2'-azobisisobutyronitrile is the total mass of divinylbenzene and polysilazane containing carbon-carbon double bonds 2% of the quality, the ratio of the quality of the acetonitrile to the total mass of divinylbenzene and carbon-carbon double bond polysilazane is 16:1;

[0029] Step 2. Put the mixed liquid obtained in Step 1 into a round-bottomed flask, pass it through argon gas, heat it to 50°C for 10 hours, then wash it repeatedly with methanol and tetrahydrofuran, vacuum filter and vacuum dry it for 24 hours to obtain initial powder;

[0030] Step 3. Under the protection of nitrogen, the initial pow...

Embodiment 2

[0061] The preparation method of the present embodiment comprises the following steps:

[0062] Step 1, preparing divinylbenzene, carbon-carbon double bond-containing polysilazane, 2,2'-azobisisobutyronitrile and acetonitrile into a mixed liquid; the quality of divinylbenzene in the mixed liquid is two 15% of the total mass of vinylbenzene and polysilazane containing carbon-carbon double bonds, the mass of the 2,2'-azobisisobutyronitrile is the total mass of divinylbenzene and polysilazane containing carbon-carbon double bonds 1.5% of the mass, the ratio of the mass of the acetonitrile to the total mass of divinylbenzene and carbon-carbon double bond polysilazane is 16:1;

[0063] Step 2: Put the mixed liquid obtained in Step 1 into a round-bottomed flask, pass through nitrogen gas, heat to 55°C for 12 hours, then wash repeatedly with methanol and tetrahydrofuran, vacuum filter and vacuum dry for 24 hours to obtain the initial Powder;

[0064] Step 3. Under the protection of...

Embodiment 3

[0082] The preparation method of the present embodiment comprises the following steps:

[0083] Step 1, preparing divinylbenzene, carbon-carbon double bond-containing polysilazane, 2,2'-azobisisobutyronitrile and acetonitrile into a mixed liquid; the quality of divinylbenzene in the mixed liquid is two 25% of the total mass of vinylbenzene and polysilazane containing carbon-carbon double bonds, and the mass of 2,2'-azobisisobutyronitrile is the total mass of divinylbenzene and polysilazane containing carbon-carbon double bonds. 2.5% of the mass, the ratio of the mass of the acetonitrile to the total mass of divinylbenzene and carbon-carbon double bond polysilazane is 16:1;

[0084] Step 2. Put the mixed liquid obtained in Step 1 into a round-bottomed flask, pass it through argon gas, heat it to 60°C for 8 hours, then wash it repeatedly with methanol and tetrahydrofuran, vacuum filter and dry it in vacuum for 24 hours to obtain initial powder;

[0085] Step 3. Under the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com