General synthesis method of tantalum pentoxide photocatalytic material with three-dimensional ordered network structure

A technology with network structure and three-dimensional order, which is applied in tantalum compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high carrier recombination rate and low specific surface area , to achieve the effects of reducing barriers, high porosity, and improving light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

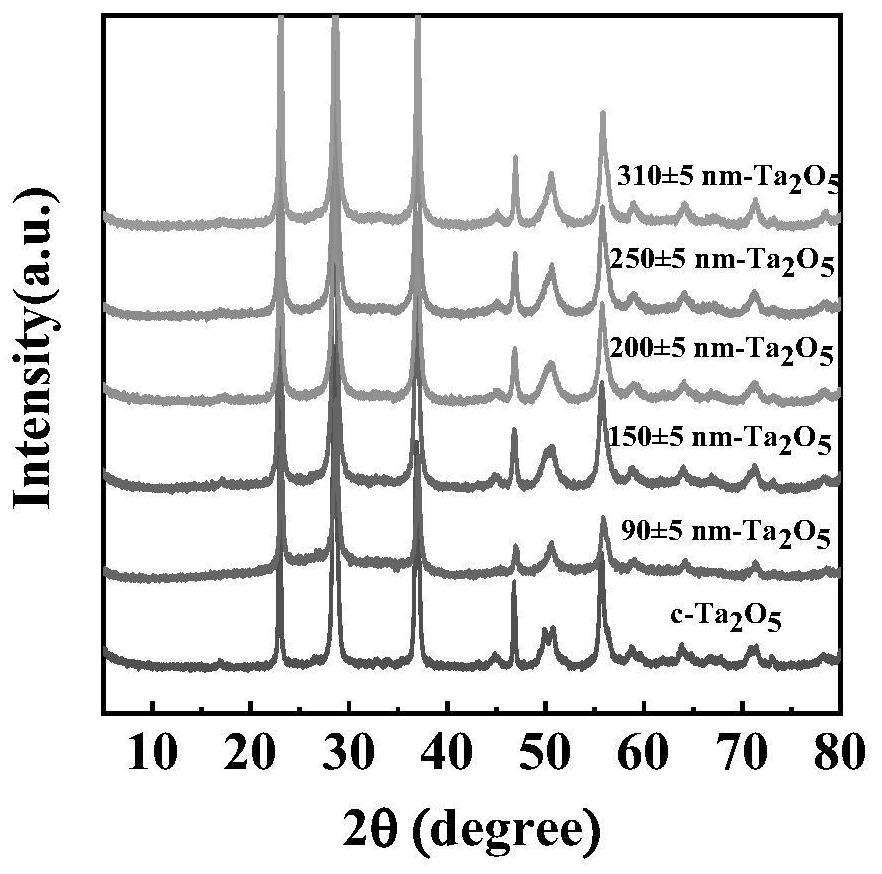

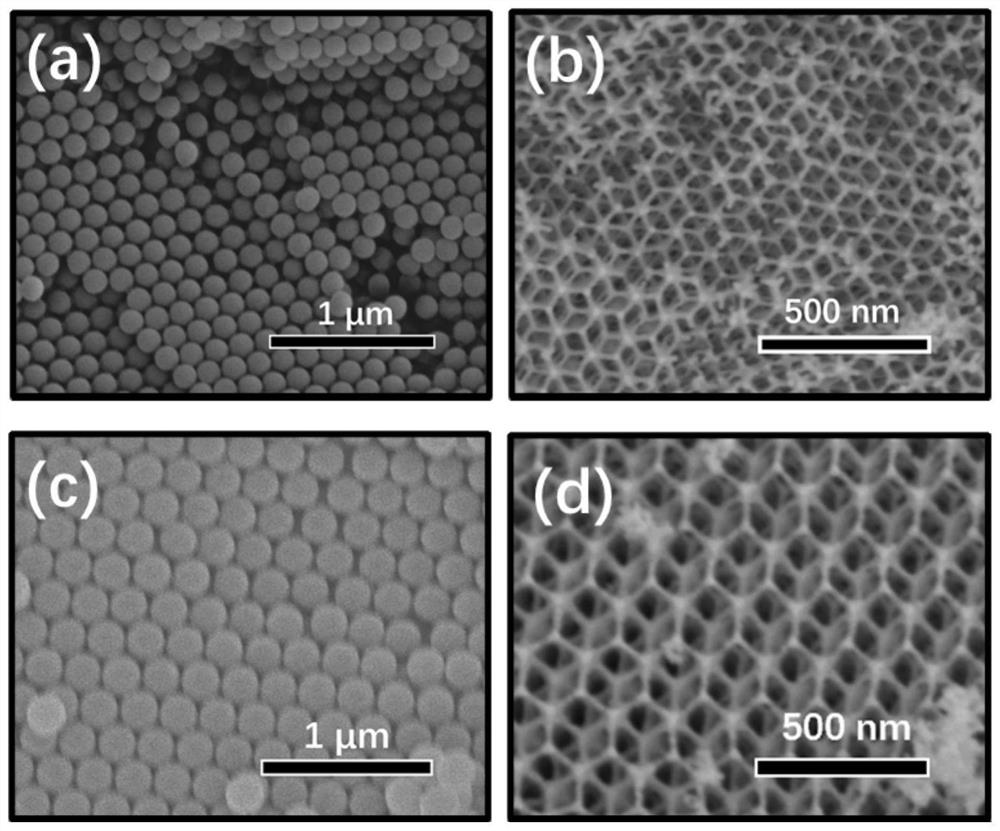

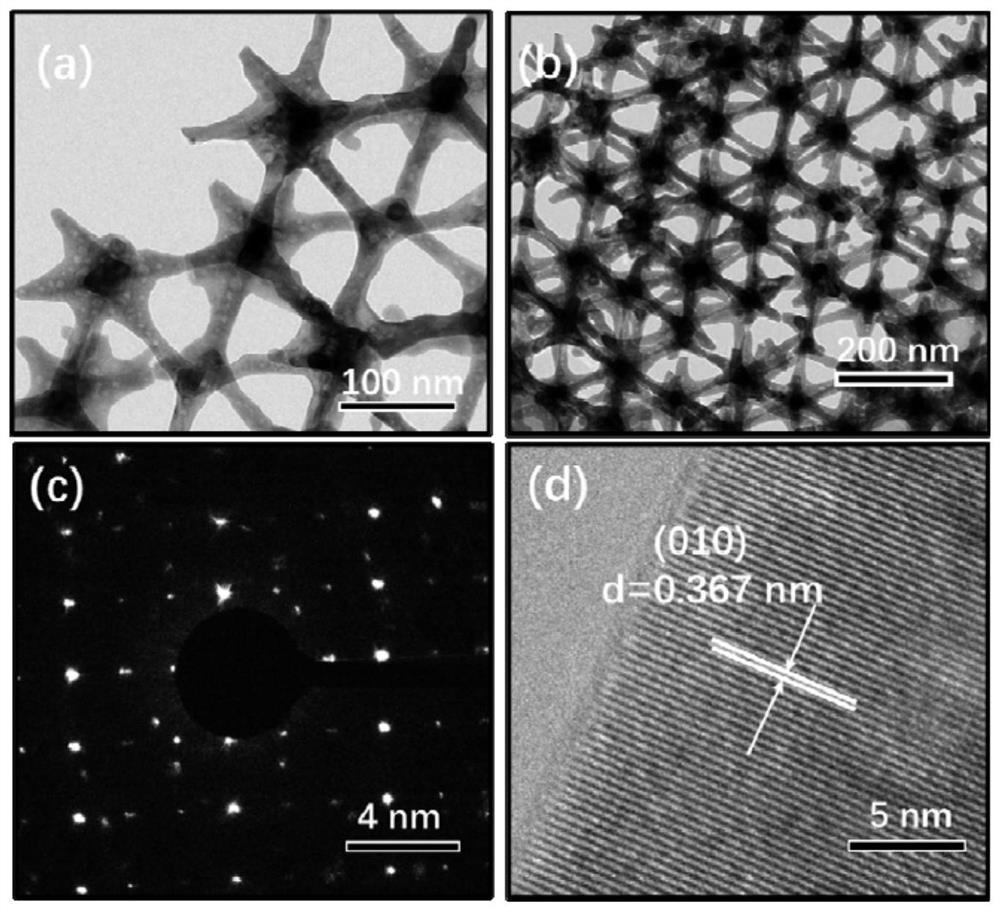

Embodiment 1

[0033] First, take TaCl 5 (1.7g) was added to anhydrous ethanol (22mL) solution and stirred to dissolve, and impurities were filtered out, and then 4g of PMMA pellet template was added to the filtrate, left to stand for 8h, and vacuum filtered to obtain PMMA containing tantalum ethoxide in the gap. It was then placed in a tube furnace, fed with nitrogen, heated to 573K, and kept for 2 hours, and then taken out after cooling down to room temperature. Next, place it in a muffle furnace, raise the temperature to 973K, and keep it for 2h. Get a three-dimensional ordered network structure Ta 2 o 5 .

Embodiment 2

[0035] First, take TaCl 5 (1.8g) was added to anhydrous ethanol (20mL) solution and stirred to dissolve, and impurities were filtered out, and then 7g of PMMA pellet template was added to the filtrate, left to stand for 8h, and vacuum filtered to obtain PMMA containing tantalum ethoxide in the gap. It was then placed in a tube furnace, fed with nitrogen, heated to 573K, and kept for 2 hours, and then taken out after cooling down to room temperature. Next, place it in a muffle furnace, raise the temperature to 973K, and keep it for 1h. Get a three-dimensional ordered network structure Ta 2 o 5 .

Embodiment 3

[0037] First, take TaCl 5(2g) was added into anhydrous ethanol (25mL) solution and stirred to dissolve, and impurities were filtered out, and then 4g of PMMA pellet template was added to the filtrate, left to stand for 8h, and vacuum filtered to obtain PMMA containing tantalum ethoxide in the gap. It was then placed in a tube furnace, fed with nitrogen, heated to 573K, and kept for 2 hours, and then taken out after cooling down to room temperature. Next, place it in a muffle furnace, raise the temperature to 973K, and keep it for 2h. Get a three-dimensional ordered network structure Ta 2 o 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com