Water purifier filter paper and preparation method thereof

A kind of technology of filter paper and water purifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention discloses a filter paper for a water purifier, which comprises the following raw materials with the proportion parameters by weight: 48% of activated carbon, 42.6% of hardwood pulp, 9.4% of polyester fiber, 1.4% of glass fiber, 0.08% of cationic polyacrylamide, alkane 0.2% of ketene dimer, 0.7% of polyamide epichlorohydrin and 9% of acrylate resin.

[0027] The average fiber diameter of the glass fiber is 1.9μm, the aspect ratio is 27.5, the bulk density is 2.8g / cm 3 , and the strength is 3350MPa. The fiber fineness of the polyester fiber is 2.75dtex, the fiber length is 6.5mm, the bulk density is 1.4g / cm 3 , the modulus of elasticity is 3600GPa, and the elongation at break is 12%.

Embodiment 2

[0029] A water purifier filter paper, comprising the following raw materials by weight ratio parameters: 46% of activated carbon, 42% of hardwood pulp, 9% of polyester fiber, 1% of glass fiber, 0.04% of cationic polyacrylamide, alkyl ketene di Polymer 0.1%, polyamide epichlorohydrin 0.5%, and acrylate resin 8%.

[0030] The average fiber diameter of the glass fiber is 1.5μm, the aspect ratio is 25, the bulk density is 2.7g / cm 3 , and the strength is 3200MPa. The fiber fineness of the polyester fiber is 1.3dtex, the fiber length is 5mm, the bulk density is 1.3g / cm3, the modulus of elasticity is 3200GPa, and the elongation at break is 11%.

Embodiment 3

[0032] A filter paper for a water purifier, comprising the following raw materials in proportion by weight: 50% of activated carbon, 43% of hardwood pulp, 9.8% of polyester fiber, 1.8% of glass fiber, 0.12% of cationic polyacrylamide, alkyl ketene di Polymer 0.3%, polyamide epichlorohydrin 0.9%, and acrylate resin 10%.

[0033] The average fiber diameter of the glass fiber is 2.3μm, the aspect ratio is 30, the bulk density is 2.9g / cm 3 , and the strength is 3500MPa. The fiber fineness of the polyester fiber is 4.2dtex, the fiber length is 8mm, the bulk density is 1.5g / cm3, the elastic modulus is 4000GPa, and the elongation at break is 13%.

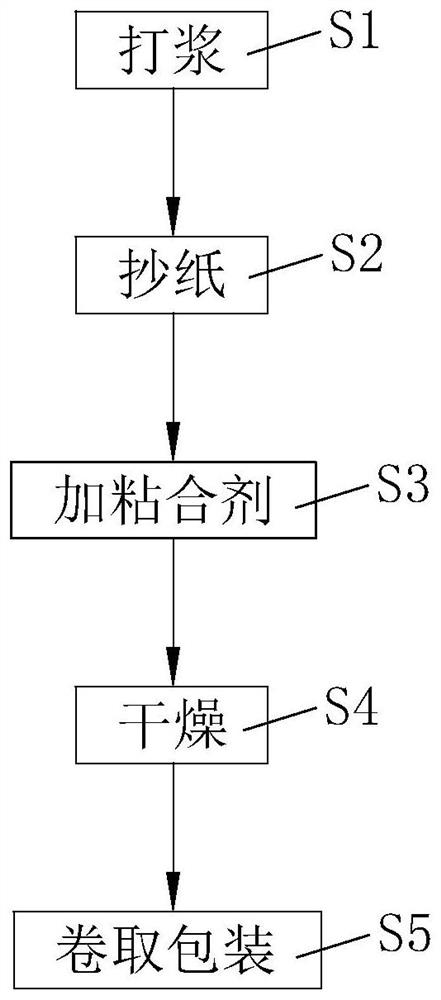

[0034] The invention also discloses a preparation method of filter paper for a water purifier, comprising the following steps:

[0035] S1, beating: Take hardwood pulp by weight, add it to the pulper for pulping, add a certain proportion of polyester fiber and glass fiber to the pulp after beating, stir and disperse, and form a stable sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com