Cobalt-free nickel-free positive electrode material and preparation method thereof and battery

A nickel positive electrode and battery technology, applied in cobalt-free and nickel-free positive electrode materials, its preparation method and battery field, can solve the problems of restricting battery cost and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

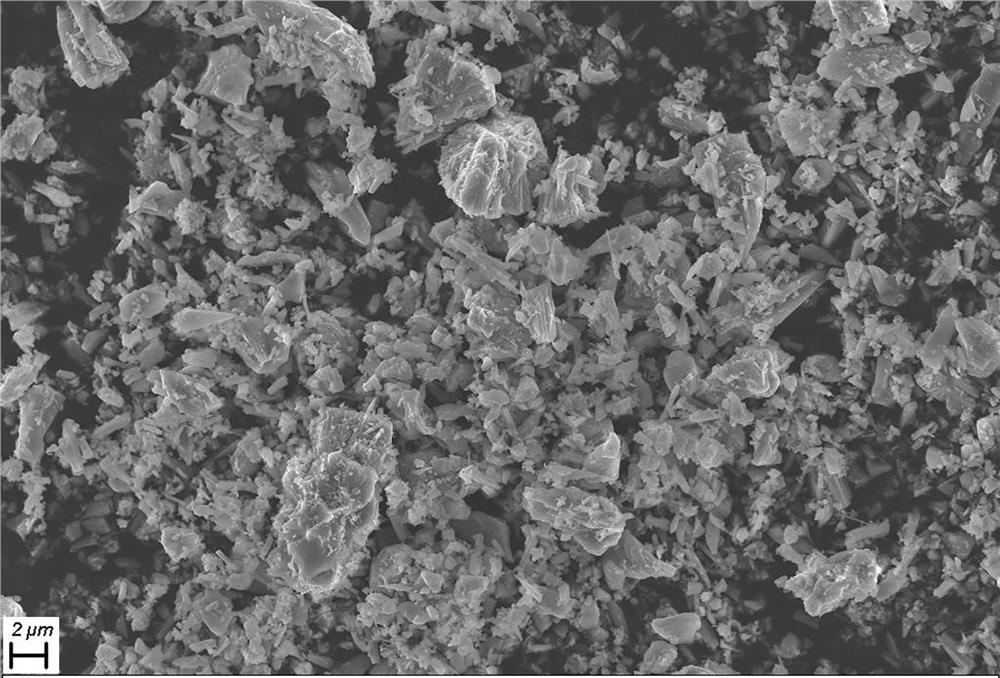

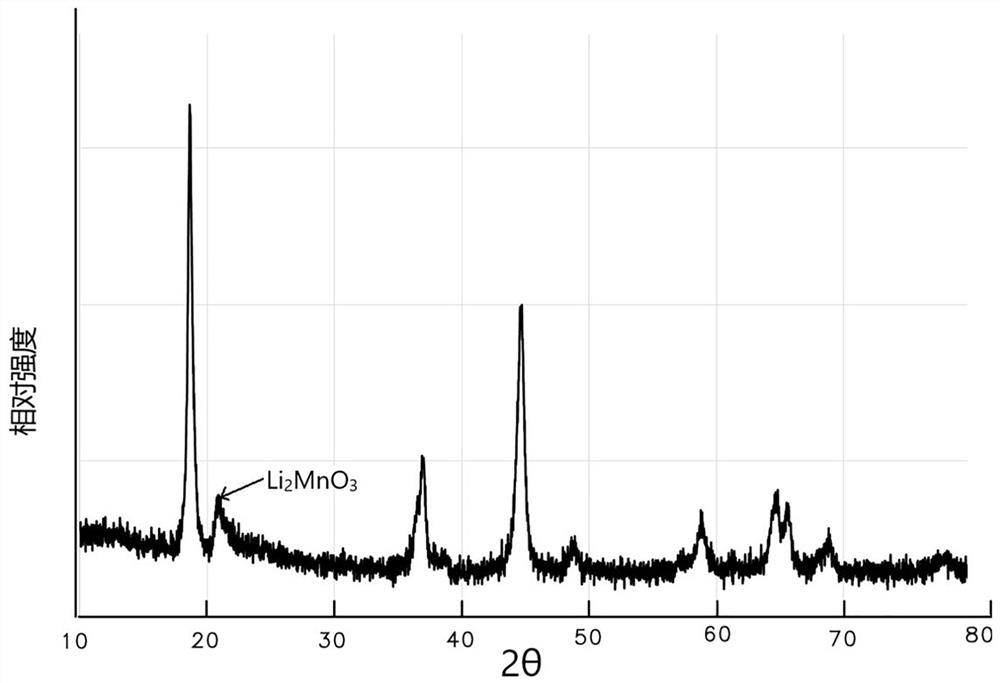

[0051] This embodiment provides a method for preparing a cobalt-free and nickel-free cathode material, and the preparation method specifically includes the following steps:

[0052] (I) Mixing lithium carbonate, sodium carbonate and manganese carbonate, the molar ratio of lithium element, sodium element and manganese element is 0.25:1:0.75, in an air atmosphere, heating at 750 ° C for 10h to prepare the cobalt-free and nickel-free Matrix material, the general formula is NaLi 0.25 Mn 0.75 O 2 , the air flow is 7.5L / min;

[0053] (II) The cobalt-free and nickel-free base material prepared in step (I), lithium carbonate and MnO are mixed to obtain a mixture, the molar ratio of lithium element and manganese element in the mixture is 1.2:1, and the melting reaction is carried out at 600 ° C for 6 hours, Add water to the reacted material and stir and wash for 10min, the quality of the added water is twice the quality of the material, and dry after washing;

[0054] (III) The dri...

Embodiment 2

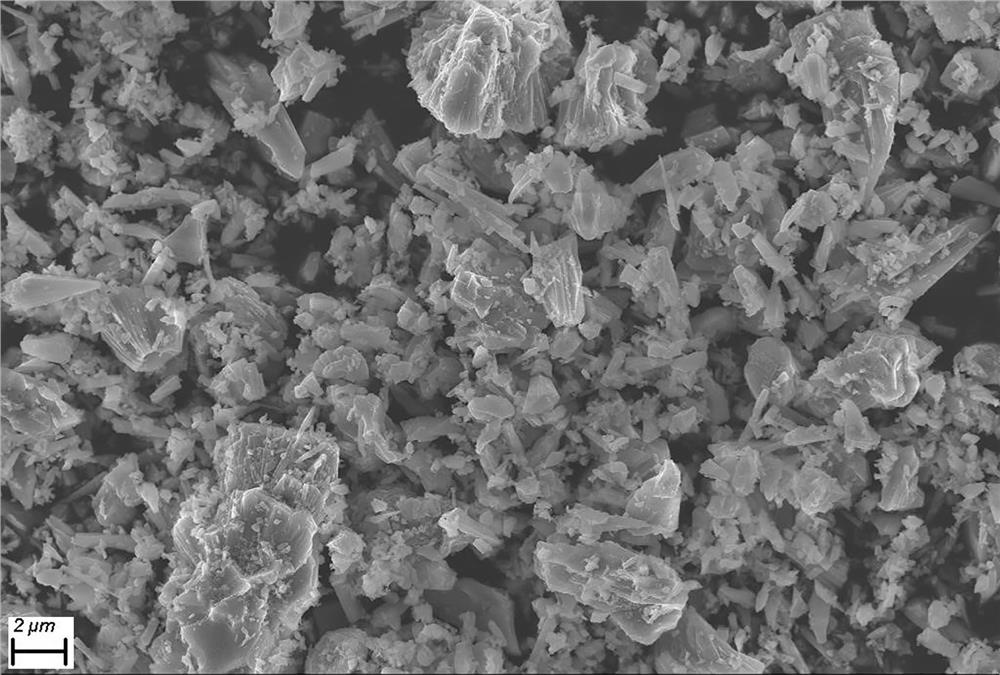

[0057] This embodiment provides a method for preparing a cobalt-free and nickel-free positive electrode material, and the preparation method specifically includes the following steps:

[0058] (I) Mixing lithium hydroxide, sodium acetate and manganese monoxide, the molar ratio of lithium element, sodium element and manganese element is 0.25:1:0.75, in an air atmosphere, heating at 500 ℃ for 12h to prepare the cobalt-free Nickel-free base material, the general formula is NaLi 0.25 Mn 0.75 O 2, the air flow is 5L / min;

[0059] (II) The cobalt-free and nickel-free base material prepared in step (I), lithium hydroxide and Mn 3 O 4 Mixing to obtain a mixture, the molar ratio of lithium element and manganese element in the mixture is 0.9:1, and the melting reaction is carried out at 400 ° C for 8 hours. Water is added to the reacted material and stirred and washed for 10 minutes. The mass of water added is twice the mass of the material. , washed and dried;

[0060] (III) The ...

Embodiment 3

[0063] This embodiment provides a method for preparing a cobalt-free and nickel-free positive electrode material, and the preparation method specifically includes the following steps:

[0064] (I) Lithium chloride, sodium chloride and manganese trioxide are mixed, the molar ratio of lithium element, sodium element and manganese element is 0.25:1:0.75. Cobalt-free and nickel-free base material, the general formula is NaLi 0.25 Mn 0.75 O 2 , the air flow is 10L / min;

[0065] (II) The cobalt-free and nickel-free base material prepared in step (I), lithium chloride and MnCO 3 Mixing to obtain a mixture, the molar ratio of lithium element and manganese element in the mixture is 1.5:1, and the melting reaction is carried out at 800 ° C for 4 hours. Water is added to the reacted material and stirred and washed for 10 minutes. The mass of water added is twice the mass of the material. , washed and dried;

[0066] (III) The dried cobalt-free and nickel-free cathode material is fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com