Tributyrin microcapsule powder and preparation method thereof

A technology of tributyrin and microcapsule powder is applied in the direction of food shearing, food forming, food science, etc., which can solve the problems of poor user adaptability and compliance, inconvenient use, butyric acid irritation, etc. Good market value, improved stability, and the effect of being conducive to industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of tributyrin microcapsule powder

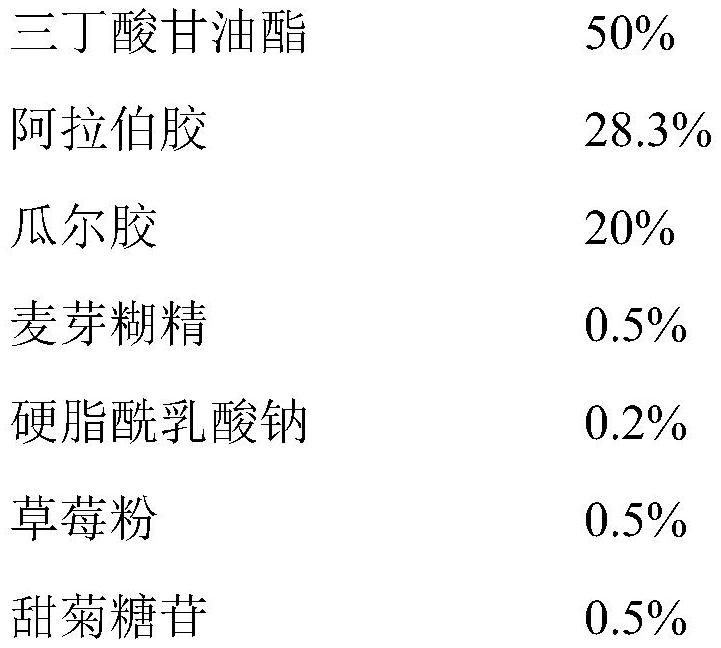

[0022] A tributyrin microcapsule powder comprises the following components by weight percentage:

[0023]

[0024] The production method is as follows:

[0025] (1) Mix the formulated amount of gum arabic, guar gum, maltodextrin, sodium stearoyl lactylate, strawberry powder and steviol glycoside in water, shear at 2800r / min until uniformly dispersed, and obtain an aqueous phase solution.

[0026] (2) Weighing the tributyrin of the recipe amount and slowly adding it to the aqueous phase solution described in step (1), and shearing at 2800r / min for 15min to prepare the primary emulsion.

[0027] (3) Homogeneously emulsifying the primary emulsion obtained in step (2) for 5 minutes under 20Mpa high pressure to obtain a uniform emulsion.

[0028] (4) Put the homogeneous emulsion homogenized in step (3) into the centrifugal spray drying tower for spray granulation. 15HZ, prepared into microcapsule powder.

Embodiment 2

[0029] Embodiment 2: Preparation of tributyrin microcapsule powder

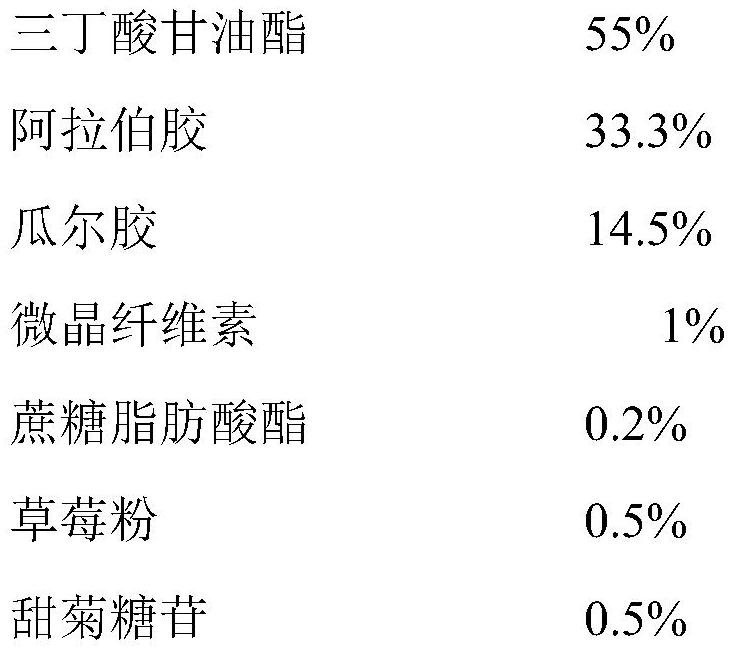

[0030] A tributyrin microcapsule powder comprises the following components by weight percentage:

[0031]

[0032] The production method is as follows:

[0033] (1) Mix the formulated amount of gum arabic, guar gum, microcrystalline fiber, sucrose fatty acid ester, strawberry powder and steviol glycoside in water, shear at 2800r / min until uniformly dispersed, and obtain an aqueous phase solution.

[0034] (2) Weighing the tributyrin of the recipe amount and slowly adding it to the aqueous phase solution described in step (1), and shearing at 2800r / min for 15min to prepare the primary emulsion.

[0035] (3) Homogeneously emulsifying the primary emulsion obtained in step (2) for 5 minutes under 20Mpa high pressure to obtain a uniform emulsion.

[0036] (4) Put the homogeneous emulsion homogenized in step (3) into the centrifugal spray drying tower for spray granulation. 15HZ, prepared into microcapsule po...

Embodiment 3

[0037] Embodiment 3: Preparation of tributyrin microcapsule powder

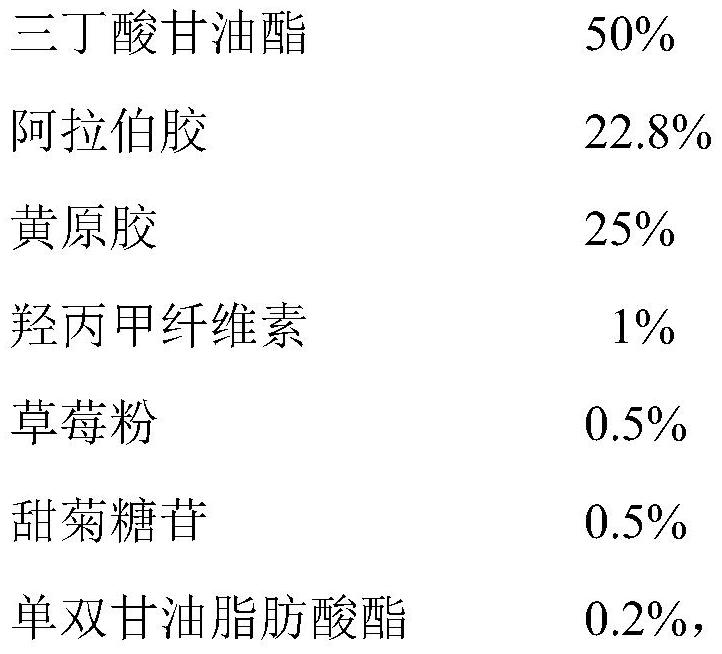

[0038] A tributyrin microcapsule powder comprises the following components by weight percentage:

[0039]

[0040] The production method is as follows:

[0041] (1) Mix the formulated amount of gum arabic, xanthan gum, hypromellose, mono-diglyceride fatty acid esters, strawberry powder and steviol glycosides in water, shear at 2800r / min until uniformly dispersed, and obtain a water phase solution.

[0042] (2) Weighing the tributyrin of the recipe amount and slowly adding it to the aqueous phase solution described in step (1), and shearing at 2800r / min for 15min to prepare the primary emulsion.

[0043] (3) Homogeneously emulsifying the primary emulsion obtained in step (2) for 5 minutes under 20Mpa high pressure to obtain a uniform emulsion.

[0044] (4) Put the homogeneous emulsion homogenized in step (3) into the centrifugal spray drying tower for spray granulation. 15HZ, prepared into microcapsule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com