Application of nickel-based catalyst with high-specific-surface-area hydrophilic activated carbon as carrier in catalytic hydrogenation hydrolysis

A high specific surface area, nickel-based catalyst technology, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrolysis preparations, etc., can solve the problems of improving atomic utilization, difficulty, etc. The effect of high selectivity, high yield and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

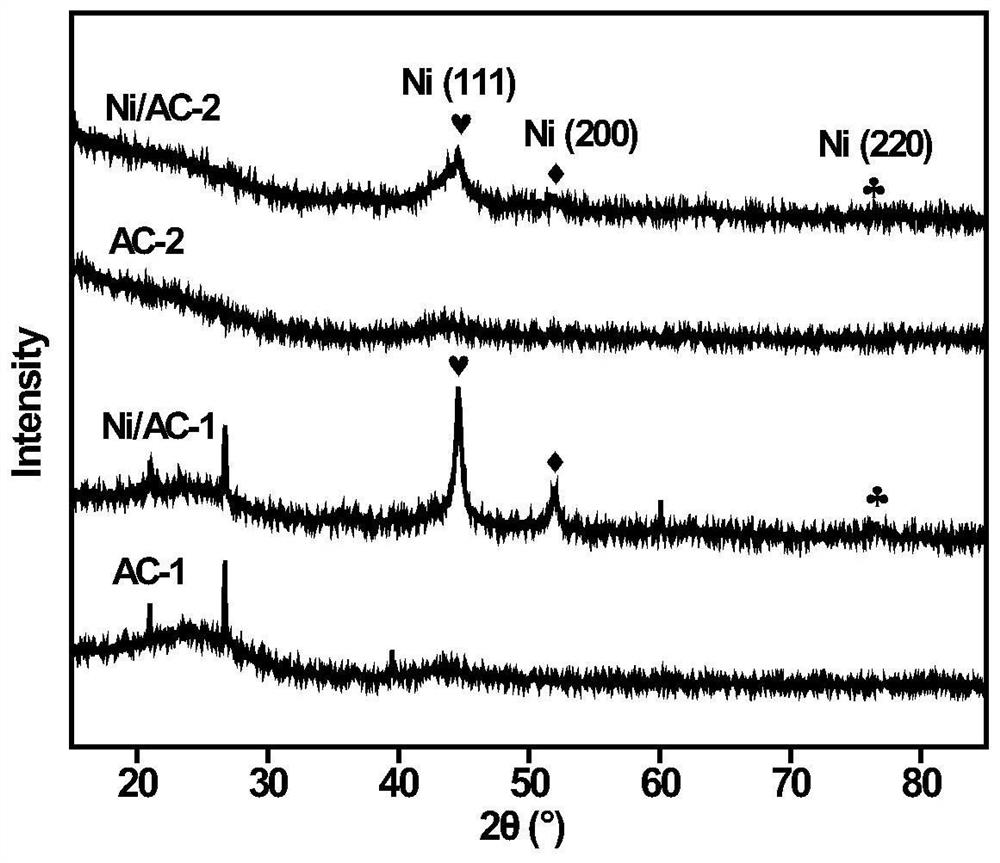

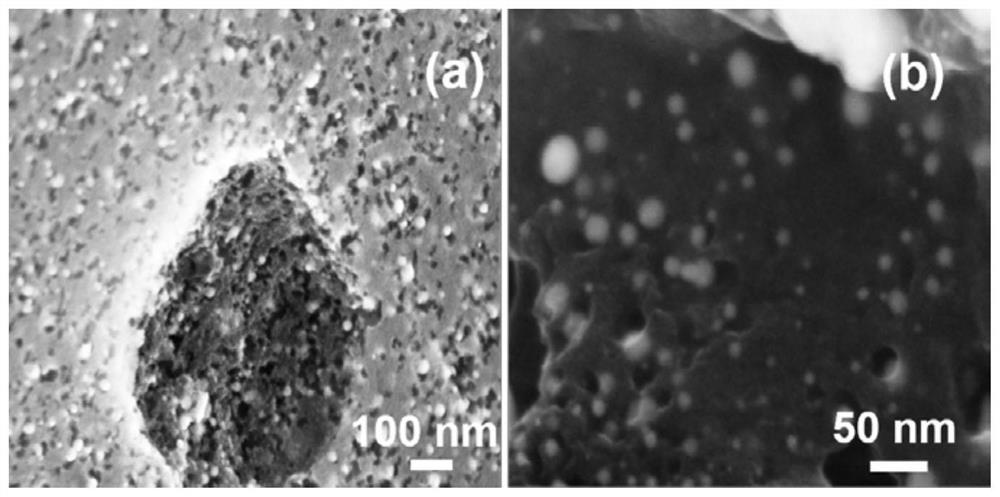

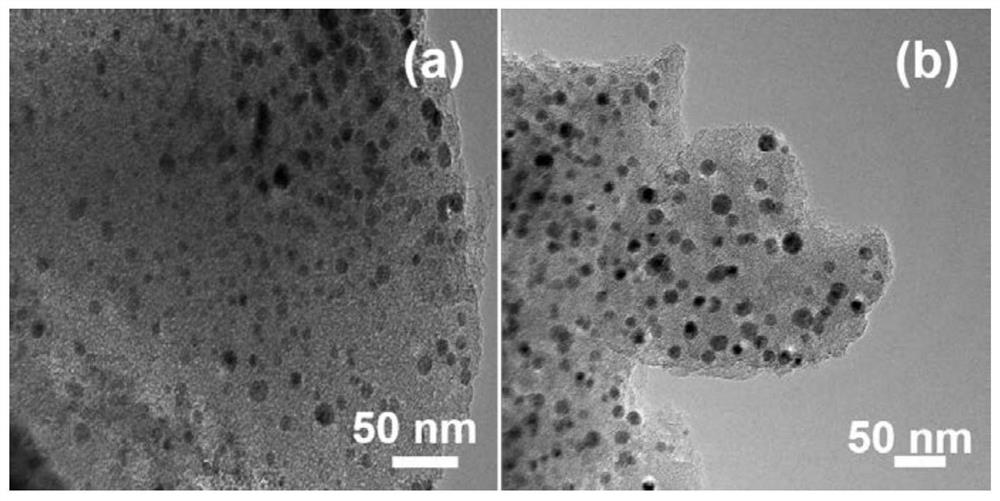

[0025] Embodiment: preparation catalyst Ni / AC-2

[0026] 1.65g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) put into beaker, add 5mL deionized water. After stirring until it is completely dissolved, add 3 g of high specific surface area hydrophilic activated carbon (AC-2) carrier into the above solution, and continue stirring to ensure a high degree of dispersion. Then the mixed solution was vacuum impregnated in a vacuum box for 24 h. The impregnated mixture was dried at 105°C for 12h, then calcined in an argon (Ar) atmosphere at 450°C for 3h at a gas flow rate of 70mL / min, followed by hydrogen (H at 450°C) 2 ) atmosphere for 3 hours, and the gas flow rate is also 70mL / min. After the reduction, the gas flow rate is 70mL / min under an argon (Ar) atmosphere, cooled to room temperature, and sealed for storage. The obtained Ni / AC catalyst was named Ni / AC-2.

Embodiment 2

[0040] Embodiment 2: the catalytic reaction of diphenyl ether (DPE)

[0041] (1) Put 100mg of reaction substrate diphenyl ether, 50mg of catalyst and 20mL of isopropanol together into a 100mL stainless steel autoclave, seal and pass through hydrogen to remove the residual air in the reactor;

[0042] (2) Continuously feed hydrogen at room temperature to pressurize the reactor to 1MPa, then raise the temperature to the required reaction temperature of 180°C, and stir the reaction for 120min at a vigorous stirring speed of 800rpm;

[0043] (3) After the reaction, the reaction system was naturally cooled to room temperature and the pressure was released, the catalyst was removed by filtration, and the obtained organic phase was analyzed by GC-MS and GC.

[0044]Activated carbon samples AC-1, AC-2 and the Ni / AC-1 catalyst prepared by the comparative example were respectively subjected to the catalytic reaction of diphenyl ether, the reaction conditions were the same as in Example ...

Embodiment 3

[0050] The Ni / AC-2 catalyst prepared in Step 1 was used to catalyze the reaction of diphenyl ether. The reaction conditions were the same as in Example 2 except that the temperature was 160° C. and the reaction time was kept different, and the product was analyzed at the same time.

[0051] Such as Figure 6 Shown, by Ni / AC-2 catalyst catalyzed diphenyl ether C-O bond cracking effect with reaction time change result, in the reaction process, strengthen the hydrophilicity of catalyst, can obtain the hydrolysis reaction product of more than 20%, improved hydrolysis Efficiency also significantly improves the selectivity of cyclohexanol in the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com