Method for treating washing liquid in vat olive green T-T imine condensation section

A treatment method and T-T technology, applied in multi-stage water treatment, filtration treatment, precipitation treatment, etc., can solve the problems of waste of raw materials, high production costs, and reduced yield of restored olive green T, reducing energy consumption and evaporation. The technology is mature and the effect of easy filtration and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

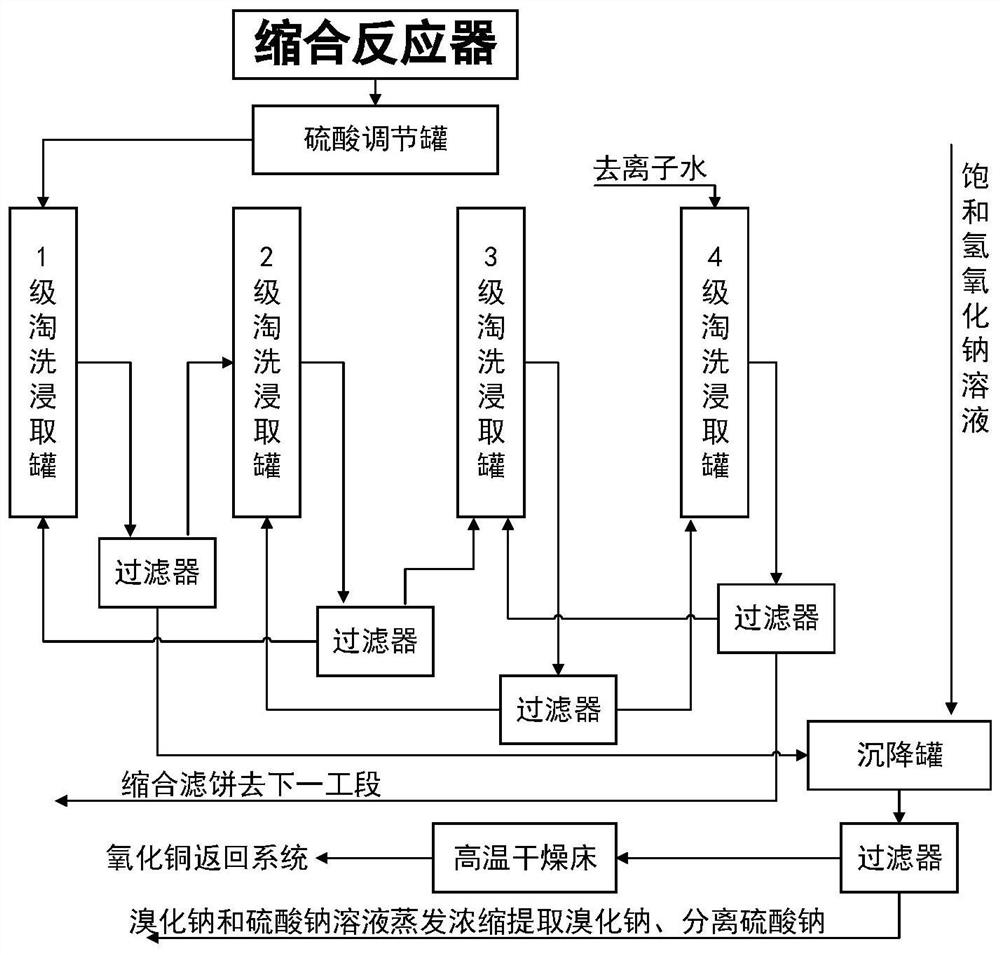

[0049] The principle diagram of the processing method of the present invention, as figure 1 shown. Pour the T-imine condensation reactant into the sulfuric acid regulating tank, add dilute sulfuric acid solution or concentrated sulfuric acid, so that all the copper oxide in the T-imine condensate is converted into copper sulfate.

[0050] Add the solid-liquid mixture in the sulfuric acid adjustment tank to the first-stage elutriation and extraction tank, use the separation liquid of the second-stage elutriation and extraction tank for leaching and elutriation, and further elutriate and leaching, and the mixture after leaching and elutriation passes through the first-stage The filter (using a filter press, the same below) is used for filtration and separation, the liquid state enters the settling tank, and the solid state (filter cake) enters the 2-stage elutriation and extraction tank.

[0051] Enter the solid state in the second-stage elutriation and extraction tank, use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com