Radiation-resistant lead-containing transparent plastic and preparation method thereof

A transparent plastic, radiation-resistant technology, used in the reduction of greenhouse gases, nuclear power generation, climate sustainability, etc. Radiation performance, controllable polymerization, good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

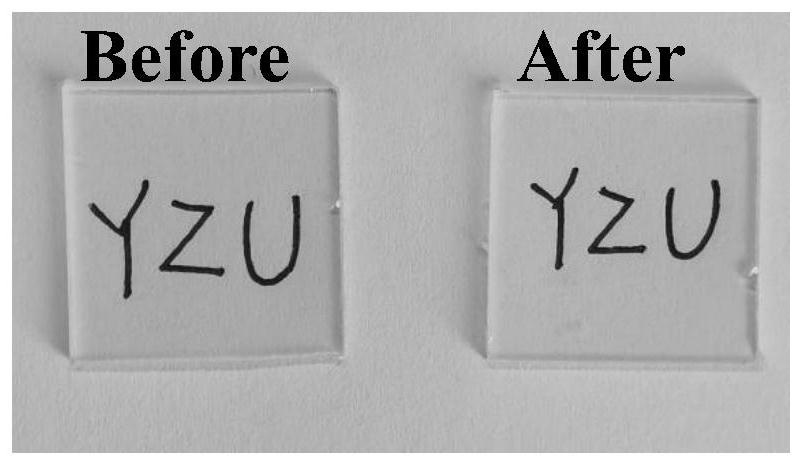

Image

Examples

preparation example Construction

[0023] (1) Preparation of the mould: wash and dry two pieces of toughened glass, and use a silica gel strip as a gasket to make a mould;

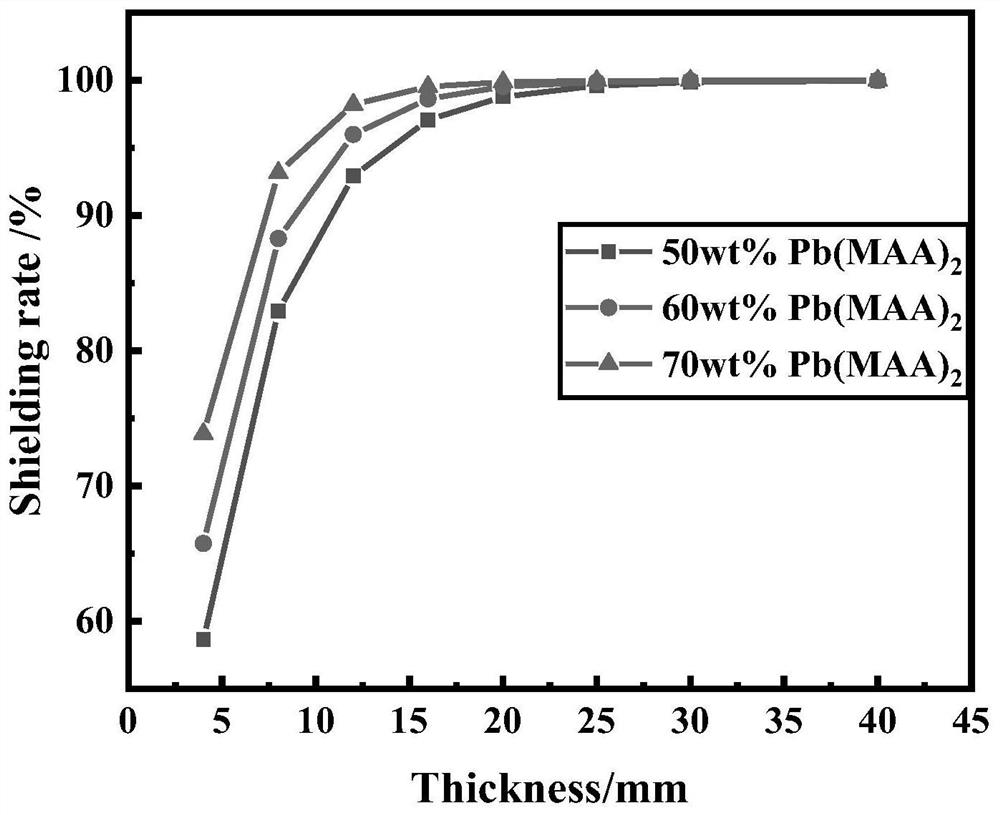

[0024] (2) Dissolving: 50.0~70.0wt% unsaturated lead carboxylate (lead methacrylate / lead acrylate), 15.0~45.0wt% optical performance modifier (acetic acid / propionic acid / butyric acid / valeric acid / caproic acid / heptanoic acid / caprylic acid / nonanoic acid), 5.0~45.0wt% acrylate monomer (methyl methacrylate / ethyl methacrylate / butyl methacrylate / methyl acrylate / ethyl acrylate / butyl acrylate One of them) into a three-necked flask, heated in a water bath to 80±5°C, stirred and dissolved until the system is clear and transparent;

[0025] (3) Prepolymerization: add 0.1wt% initiator (AIBN / AVBN), raise the temperature to 80±5°C, and prepolymerize for 1-9 minutes. At this time, the system has a certain viscosity, and then pour the prepolymer into a flat glass mold;

[0026] (4) Gradient heating polymerization: first polymerize at 50±5°C for 12 hours,...

Embodiment 1

[0029] According to the mass ratio of unsaturated lead carboxylate, optical performance modifier, and acrylic monomers, the mass ratio of 60.0wt%: 15.0wt%: 25.0wt%, weigh Pb(MAA) 2 18.0g, 4.5g of n-octanoic acid OA, 7.5g of butyl acrylate BA, and 0.03g of initiator AIBN were weighed, and the radiation-resistant transparent plastic was obtained according to the above technical scheme.

Embodiment 2

[0031] According to the mass ratio of unsaturated lead carboxylate, optical performance modifier, and acrylic monomers, the mass ratio of 60.0wt%: 20.0wt%: 20.0wt%, weigh Pb (MAA) 2 18.0g, OA 6.0g, BA 6.0g, weigh 0.03g of initiator AIBN, and make radiation-resistant transparent plastic according to the above technical scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com