Method for controllably preparing amorphous-polycrystalline hybrid bismuth telluride base film by adopting vacuum evaporation coating

A bismuth telluride-based film and vacuum evaporation technology, which is applied in vacuum evaporation plating, chemical instruments and methods, polycrystalline material growth, etc., to achieve the effects of simple method, loose production environment conditions, and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

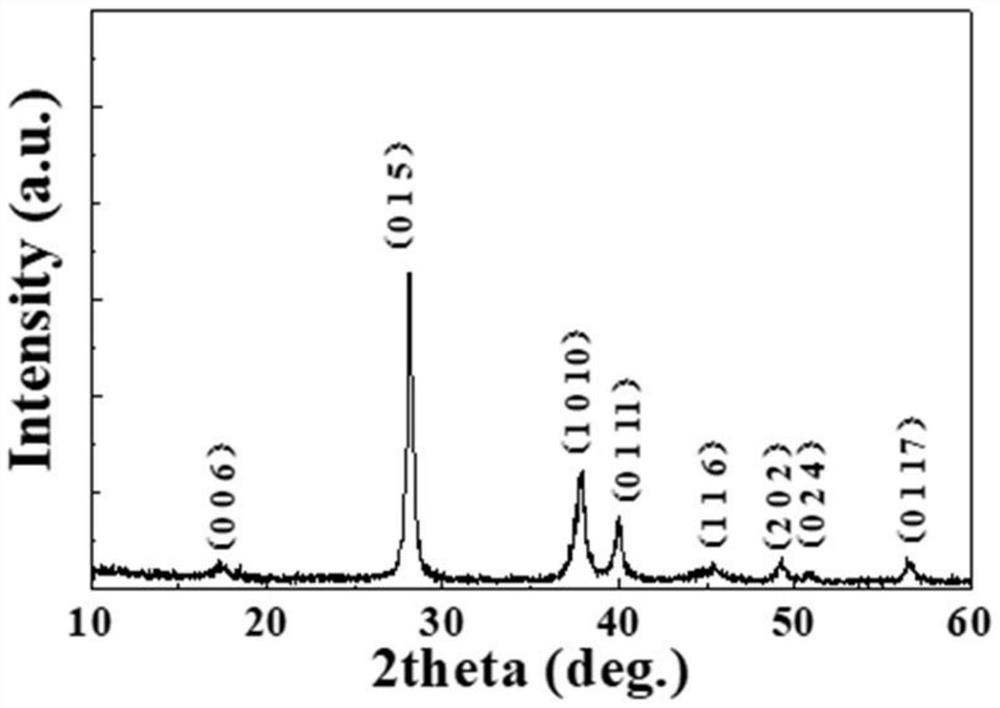

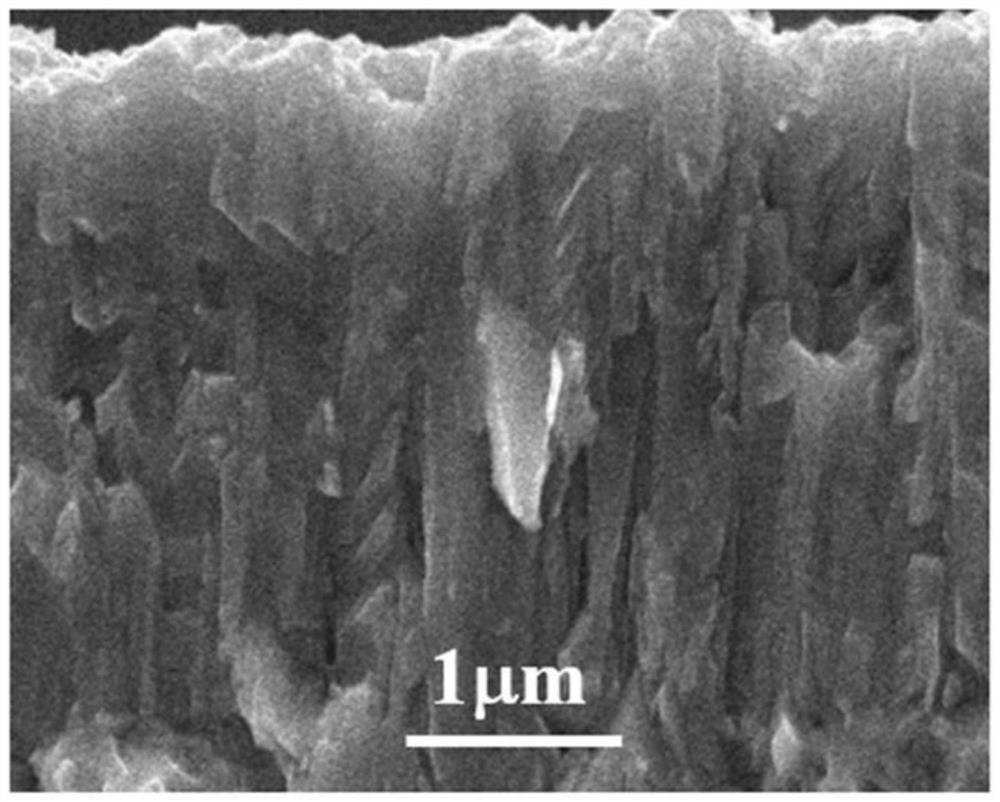

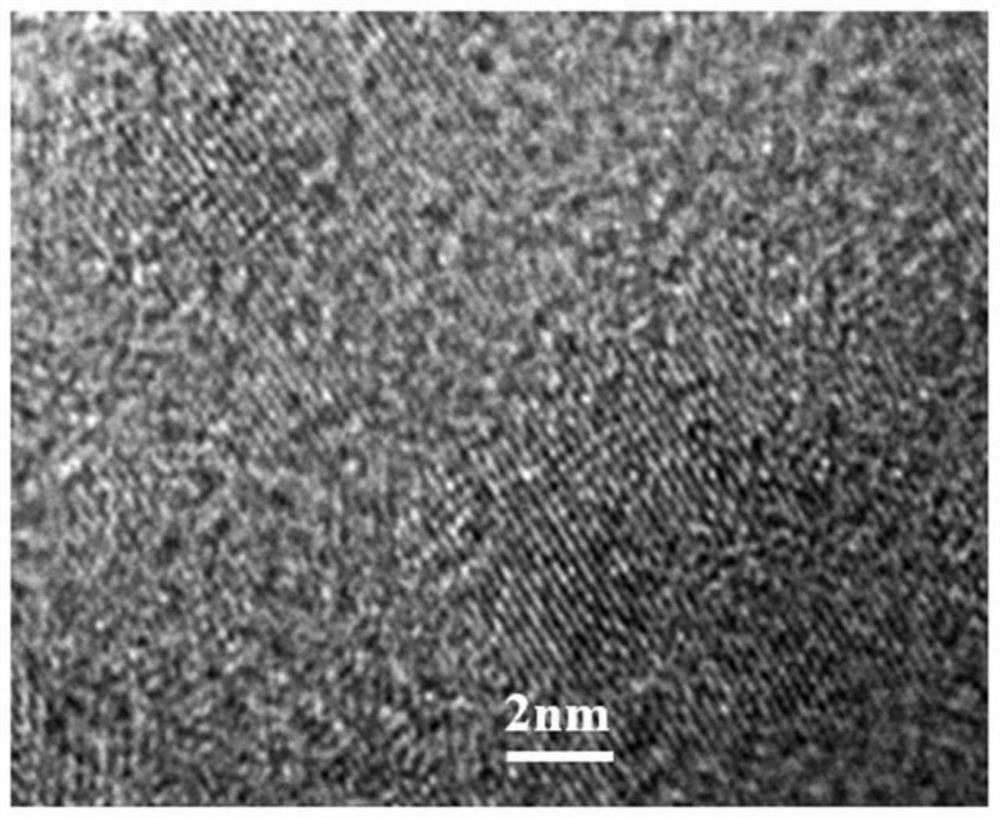

[0044] Preparation of Amorphous-Polycrystalline Hybrid Bi by Evaporation Coating on Substrate 0.5 Sb 1.5 Te 3 membrane:

[0045] (1) Bi with a mass percent purity of 99.99% 0.5 Sb 1.5 Te 3 The powder is compressed into a block under a pressure of 4MPa; the Bi 0.5 Sb 1.5 Te 3 The average particle size of the powder is less than 50 μm;

[0046] (2) The substrate was ultrasonically cleaned in absolute ethanol and deionized water for 10 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0047] (3) 0.15g of Bi 0.5 Sb 1.5 Te 3 Put the block made of the material into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the substrate on the sample stage, and adjust the distance d=8cm between the substrate and the tungsten boat;

[0048] (4) Fill the vacuum chamber with nitrogen for 3 minutes and stop, then evacuate the vacuum chamber so that the vacuum degree in the vacuum chamber reaches 3.0×10 -4 Pa;

[0049] (5) The vacuum ...

Embodiment 2

[0057]Preparation of Amorphous-Polycrystalline Hybrid Bi by Evaporation Coating on Substrate 0.5 Sb 1.5 Te 3 Membrane: (preferable)

[0058] (1) Bi with a mass percent purity of 99.99% 0.5 Sb 1.5 Te 3 The powder is compressed into a block under a pressure of 5 MPa; the Bi 0.5 Sb 1.5 Te 3 The average particle size of the powder is less than 50 μm;

[0059] (2) The substrate was ultrasonically cleaned in absolute ethanol and deionized water for 8 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0060] (3) 0.15g of Bi 0.5 Sb 1.5 Te 3 Put the block made of material into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the substrate on the sample stage, and adjust the distance d=9cm between the substrate and the tungsten boat;

[0061] (4) Fill the vacuum chamber with nitrogen for 6 minutes and stop, then evacuate the vacuum chamber so that the vacuum degree in the vacuum chamber reaches 4.0×10 -4 Pa;

[0062] (5) The...

Embodiment 3

[0070] Preparation of Amorphous-Polycrystalline Hybrid Bi by Evaporation Coating on Substrate 0.5 Sb 1.5 Te 3 membrane:

[0071] (1) Bi with a mass percent purity of 99.99% 0.5 Sb 1.5 Te 3 The powder is compressed into a block under a pressure of 5 MPa; the Bi 0.5 Sb 1.5 Te 3 The average particle size of the powder is less than 50 μm;

[0072] (2) The substrate was ultrasonically cleaned in absolute ethanol and deionized water for 5 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0073] (3) Add 0.2g of Bi 0.5 Sb 1.5 Te 3 Put the block made of material into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the substrate on the sample stage, and adjust the distance d=10cm between the substrate and the tungsten boat;

[0074] (4) Fill the vacuum chamber with nitrogen for 8 minutes and then stop, then evacuate the vacuum chamber so that the vacuum degree in the vacuum chamber reaches 5.0×10 -4 Pa;

[0075] (5) The va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com