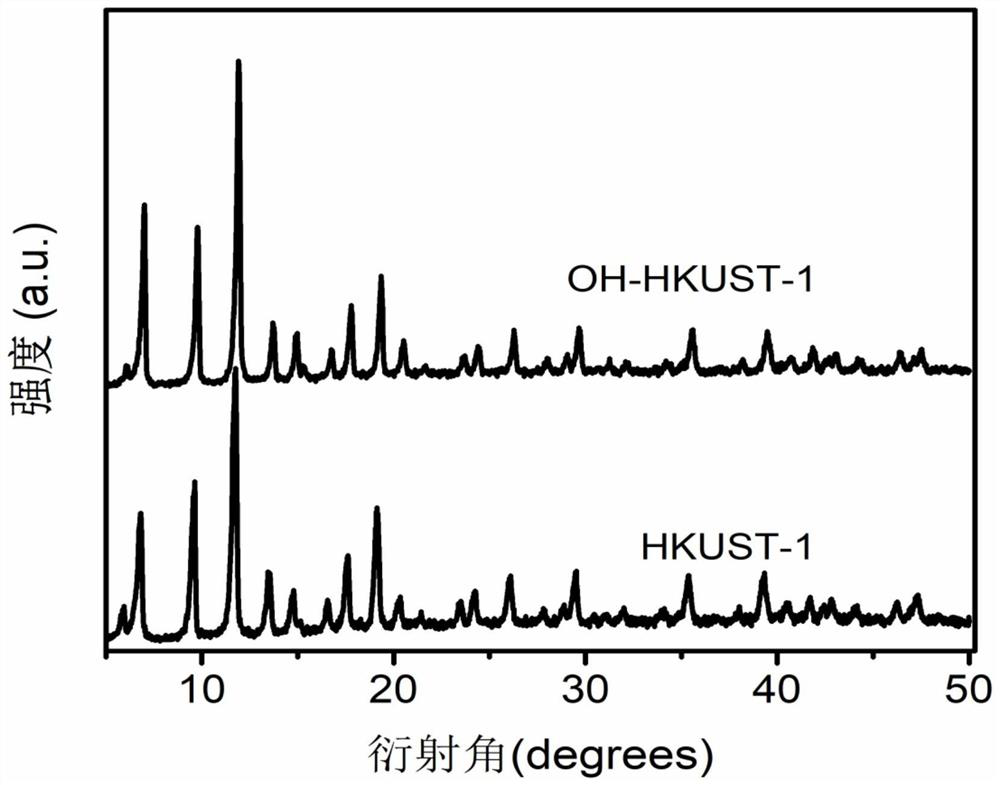

Defective metal-organic framework desulfurization adsorbent and preparation method and application thereof

An organic framework and adsorbent technology, applied in the field of defective metal-organic framework desulfurization adsorbent and its preparation, can solve the problems of short synthesis period, fast mass transfer rate, long synthesis period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

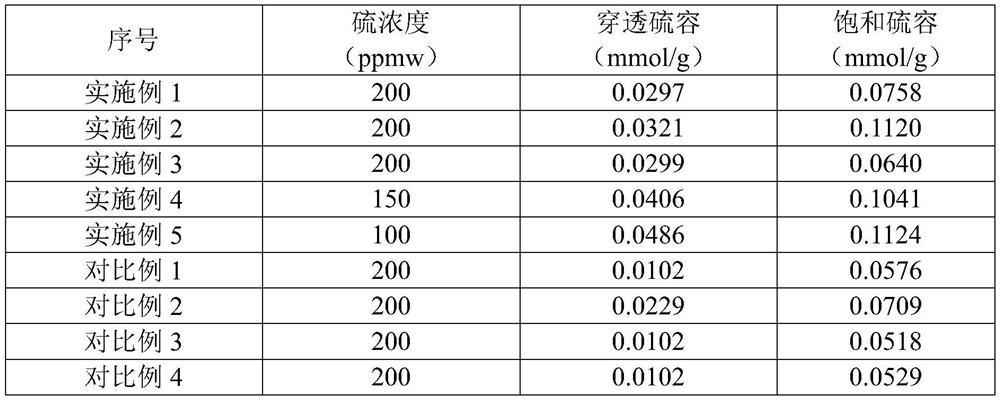

Embodiment 1

[0032] Trimellitic acid and 5-hydroxyisophthalic acid were mixed and dissolved in 15 mL ethanol solution at a ratio of 1:9, and ultrasonicated at room temperature for 15 min. Dissolve 2g of copper nitrate trihydrate in 15mL of deionized water, mix the two solutions evenly and place them in a polytetrafluoroethylene lining, place them in a microwave hydrothermal synthesizer, set the heating program to 5°C min -1 The heating rate is heated from 25°C to 100°C and kept for 15 minutes, then at 2°C min -1 The heating rate is heated to 120°C for 30min, and the power is 700W. After the reaction is completed, cool to room temperature, filter and wash with absolute ethanol and DMF solution several times, dry, extrude and grind to obtain defective metal-organic framework desulfurization adsorption agent.

[0033] On the fixed bed adsorption desulfurization device, use the adsorbent of this embodiment to evaluate the desulfurization of oil products. Use n-octane to configure simulated g...

Embodiment 2

[0035] Trimellitic acid and 5-hydroxyisophthalic acid were mixed and dissolved in 15 mL ethanol solution at a ratio of 1:4, and ultrasonicated at room temperature for 15 min. Dissolve 2g of copper nitrate trihydrate in 15mL of deionized water, mix the two solutions evenly and place them in a polytetrafluoroethylene lining, place them in a microwave hydrothermal synthesizer, set the heating program to 5°C min -1 The heating rate is heated from 25°C to 100°C and kept for 15 minutes, then at 2°C min -1 The heating rate is heated to 120°C for 30min, and the power is 700W. After the reaction is completed, cool to room temperature, filter and wash with absolute ethanol and DMF solution several times, dry, extrude and grind to obtain defective metal-organic framework desulfurization adsorption agent.

[0036]On the fixed bed adsorption desulfurization device, use the adsorbent of this embodiment to evaluate the desulfurization of oil products. Use n-octane to configure simulated ga...

Embodiment 3

[0038] Trimellitic acid and 5-hydroxyisophthalic acid were mixed and dissolved in 15 mL ethanol solution at a ratio of 3:7, and ultrasonicated for 15 min at room temperature. Dissolve 2g of copper nitrate trihydrate in 15mL of deionized water, mix the two solutions evenly and place them in a polytetrafluoroethylene lining, place them in a microwave hydrothermal synthesizer, set the heating program to 5°C min -1 The heating rate is heated from 25°C to 100°C and kept for 15 minutes, then at 2°C min -1 The heating rate is heated to 120°C for 30min, and the power is 700W. After the reaction is completed, cool to room temperature, filter and wash with absolute ethanol and DMF solution several times, dry, extrude and grind to obtain defective metal-organic framework desulfurization adsorption agent.

[0039] On the fixed bed adsorption desulfurization device, use the adsorbent of this embodiment to evaluate the desulfurization of oil products. Use n-octane to configure simulated g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com