Rubidium and tungsten co-doped titanium dioxide photocatalytic material and preparation method thereof

A photocatalytic material, titanium dioxide technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of limited photocatalytic performance of titanium dioxide materials, etc. The effect of catalytic degradation performance, easy control of conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

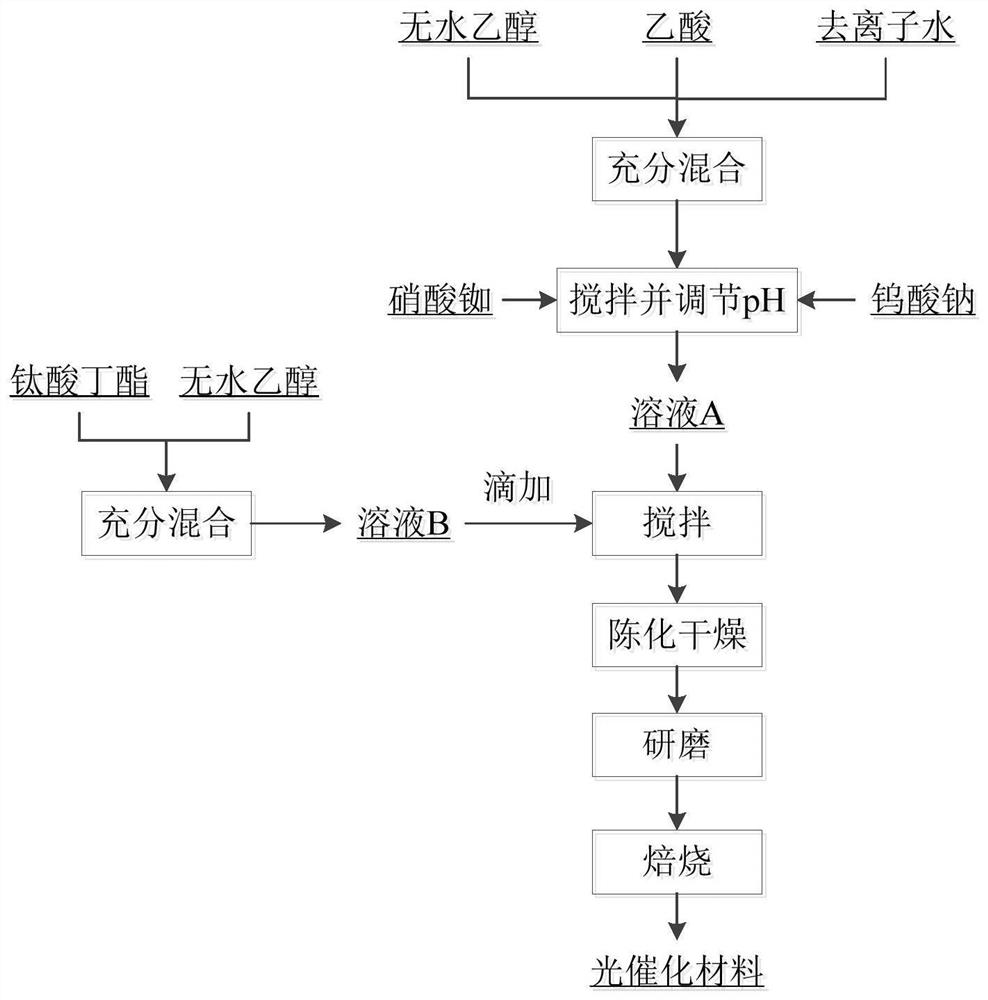

[0029] The specific operation steps for preparing rubidium and tungsten co-doped titania photocatalytic materials are as follows:

[0030] (1) Solution A preparation

[0031] Mix 70mL of absolute ethanol, 10mL of acetic acid and 20mL of deionized water evenly, then add 0.0174g of rubidium nitrate and 0.0388g of sodium tungstate, and start stirring. After they are fully dissolved, add nitric acid drop by drop to adjust the pH value of the mixed solution was 2.0, solution A was prepared.

[0032] (2) Solution B preparation

[0033] Slowly add 20 mL of butyl titanate into 70 mL of absolute ethanol and stir thoroughly to obtain solution B.

[0034] (3) Gel preparation and drying

[0035] Add solution B to solution A dropwise, and control the dropping rate to 0.75 mL / min. After the solution B was added dropwise, it was stirred for 15 min to obtain a gel. The gel was transferred into a watch glass, and placed in a fume hood to age and air-dry at a temperature of 25°C for 48 hou...

Embodiment 2

[0039] The difference between this example and Example 1 is that in step (4), the calcination temperature is 550°C. Others are the same as in Example 1. In the prepared titanium dioxide photocatalytic material co-doped with rubidium and tungsten, the molar doping ratios of rubidium and tungsten are both 0.2%.

Embodiment 3

[0041] The difference between this example and Example 1 is that in step (1), 70mL of absolute ethanol, 10mL of acetic acid and 20mL of deionized water are uniformly mixed, nitric acid is added dropwise, and the pH value of the mixed solution is adjusted to 2.0 to obtain a solution a. Others are the same as in Example 1.

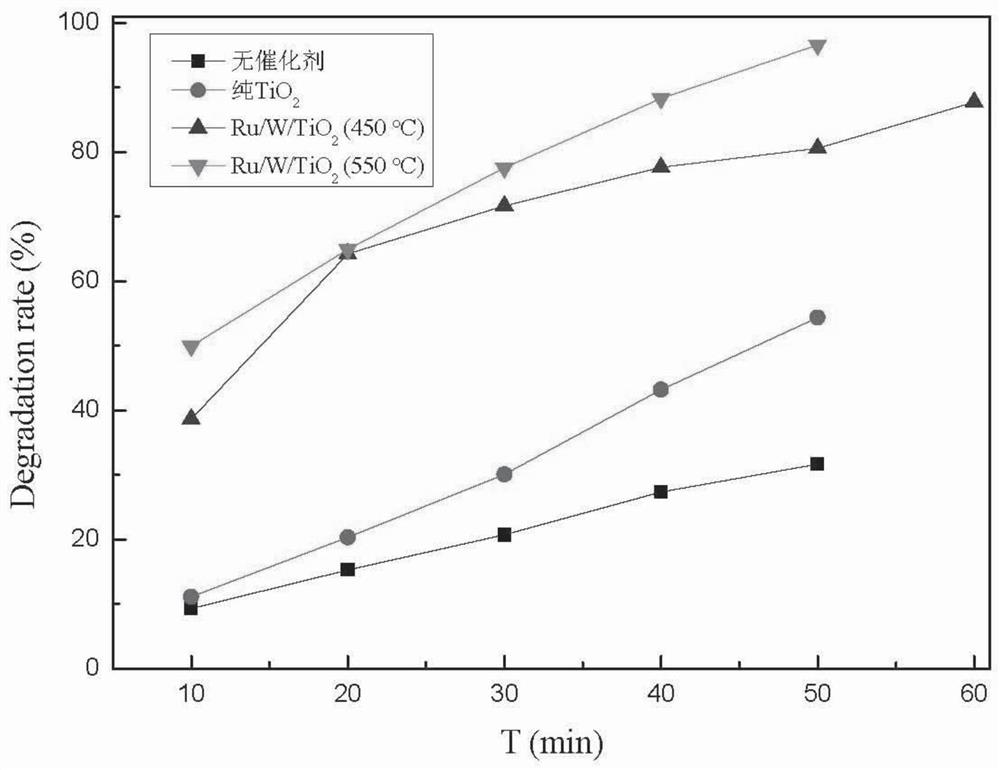

[0042] Characterization of photocatalytic performance of photocatalytic materials

[0043] With reference to the national standard GBT23762-2009 photocatalytic material aqueous solution system purification test method, the photocatalytic effect of the rubidium and tungsten co-doped titanium dioxide material obtained in embodiment 1 and embodiment 2 is evaluated, and compared with the pure titanium dioxide obtained in example 3 comparing. A 10mg / L methylene blue solution was used as the degradation solution for testing the photocatalytic effect, the light source was provided by a 300W xenon lamp, and the catalyst concentration was 1.0g / mL. The concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com