Preparation method and application of supported catalyst for catalyzing dimethyl oxalate hydrogenation

A technology for catalyzing dimethyl oxalate and supported catalysts, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as catalyst deactivation, and achieve Improve catalytic performance, improve stability and selectivity, reduce the effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

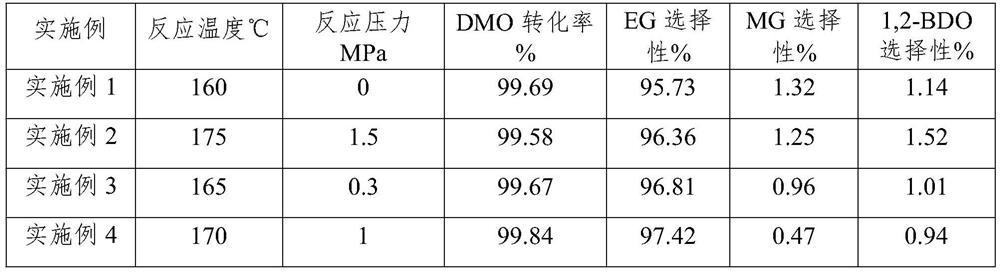

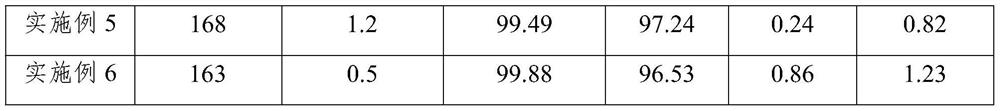

Examples

Embodiment 1

[0028] The preparation method of the supported catalyst for catalyzing the hydrogenation of dimethyl oxalate of the present embodiment, the method is:

[0029] S1, dissolving copper nitrate in deionized water a, then adding an ammonia solution whose mass fraction is 25% to obtain a precursor solution; the consumption ratio of the copper nitrate, deionized water a and the ammonia solution is 7.6g:30mL:25mL ; copper in the precursor solution exists in the form of copper ammine complex, Cu(NH 3 ) 4 (NO 3 ) 2 It is conducive to ion exchange with silanol on the surface of the carrier, and finally forms Cu-O-Si units;

[0030] S2, using the carrier (nano silica) to make the carrier absorb moisture until the water mass fraction is 1% under the conditions of constant temperature and constant humidity with a temperature of 20° C. and a relative humidity of 50% to obtain a wet carrier;

[0031] Sufficient water molecules on the wet carrier surface and the silicon-oxygen bond on the ...

Embodiment 2

[0040] The preparation method of the supported catalyst for catalyzing the hydrogenation of dimethyl oxalate of the present embodiment, the method is:

[0041] S1, copper nitrate is dissolved in deionized water a, then add the ammonia solution whose mass fraction is 28% to obtain precursor solution; the consumption ratio of described copper nitrate, deionized water a and ammonia solution is 7.6g:30mL:40mL ;

[0042] S2, under the condition of constant temperature and constant humidity of the temperature of 40 ℃ and the relative humidity of 80% of the carrier (nano silica), the carrier is hygroscopic until the water mass fraction is 3% to obtain a wet carrier;

[0043] S3, after dissolving the soluble metal salt (cerium nitrate) in deionized water b, add the wet carrier obtained in S2, stir and disperse to obtain a suspension; the consumption ratio of the soluble metal salt, deionized water b and the wet carrier is 0.4g: 100mL: 5.97g; the amount of the wet carrier is SiO 2 co...

Embodiment 3

[0048] The preparation method of the supported catalyst for catalyzing the hydrogenation of dimethyl oxalate of the present embodiment, the method is:

[0049] S1, copper nitrate is dissolved in deionized water a, then adding mass fraction is 25%~28% ammonia solution, obtains precursor solution; The consumption ratio of described copper nitrate, deionized water a and ammonia solution is 7.6g: 30mL: 30mL;

[0050] S2, the carrier (pure silicon molecular sieve molecular sieve MCM-41) at a temperature of 20 ° C and a relative humidity of 50% under the conditions of constant temperature and constant humidity, the carrier is hygroscopic until the water mass fraction is 1% to obtain a wet carrier;

[0051] S3, after dissolving the soluble metal salt (calcium nitrate) in deionized water b, add the wet carrier obtained in S2, stir and disperse to obtain a suspension; the consumption ratio of the soluble metal salt, deionized water b and the wet carrier It is 0.5g: 100mL: 6.0g; the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com