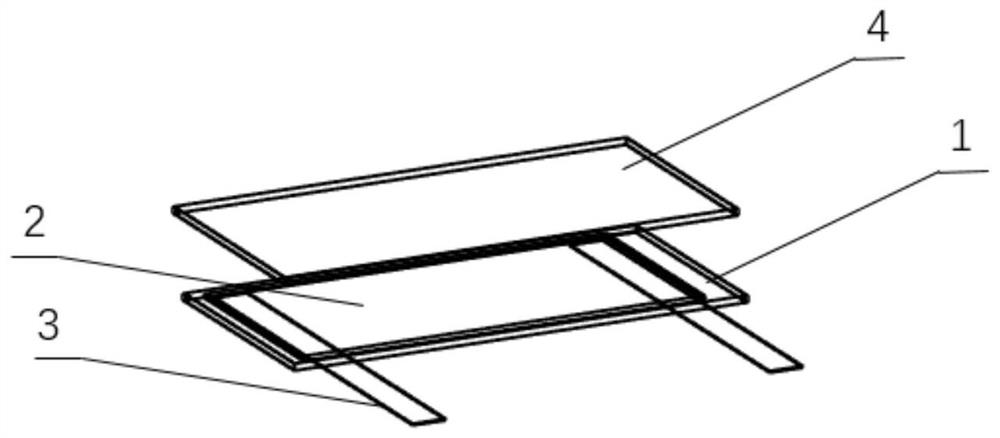

Self-repairing flexible strain sensor based on electrospun fibers and preparation method thereof

A strain sensor and electrospun fiber technology, applied in the field of sensors, can solve the problems of low sensitivity of flexible strain sensors, lack of additional functions, complex production process, etc., achieve good self-healing performance and compression resistance, improve repeatability, production simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

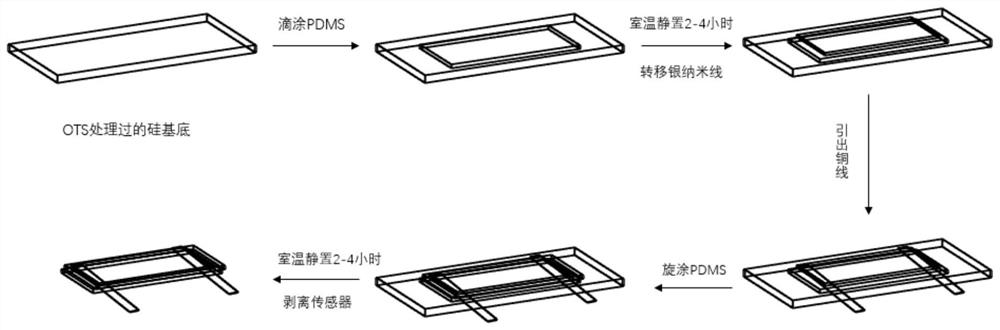

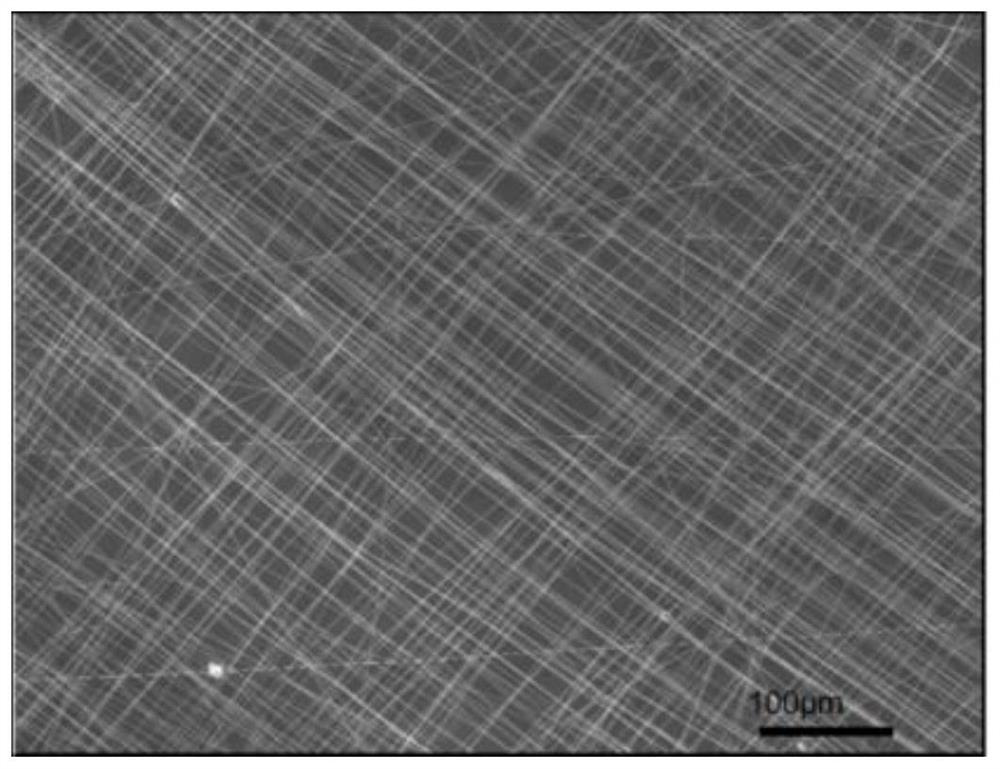

Method used

Image

Examples

Embodiment 1

[0047] 1. Place the 10 g of diamino-encapsulated polydimethylsiloxane in 100 ml of chloroform solution to form a polydimethylsiloxane solution with a mass fraction of 10%, and stir for 1 hour while keeping the temperature at 0°; Then add 0.27g isophorone diisocyanate and 0.2g 4'-methylene bis(phenyl isocyanate) dropwise and stir for 1 hour; add 10ml methanol after fully reacting to remove excess isophorone diisocyanate, and let it stand for 4 Hours until a white precipitate occurs; chloroform is evaporated above 80° to obtain a viscous solution of self-healing polydimethylsiloxane.

[0048] 2. Add the self-healing polydimethylsiloxane viscous solution dropwise onto the silicon substrate, and heat it to 80°C for two hours to cure;

[0049] 3. Dissolve 8g of polyvinyl alcohol 1788 in deionized water and configure a polyvinyl alcohol aqueous solution with a mass fraction of 10%. Stir and heat in a 70° water bath for more than 8 hours until the solution is clear and transparent; ...

Embodiment 2

[0055] 1. Place the 13 g of diamino-encapsulated polydimethylsiloxane in 150 ml of chloroform solution to form a polydimethylsiloxane solution with a mass fraction of 13%, and stir for 1.5 hours, keeping the temperature at 2°; Add 0.31g of isophorone diisocyanate and 0.22g of 4'-methylene bis(phenyl isocyanate) dropwise and stir for 1.5 hours; add 15ml of methanol after fully reacting to remove excess isophorone diisocyanate, and let stand for 4 Hours until a white precipitate occurs; chloroform is evaporated above 80° to obtain a viscous solution of self-healing polydimethylsiloxane.

[0056] 2. Add the self-healing polydimethylsiloxane viscous solution dropwise onto the silicon substrate, and heat it to 60°C for two hours before curing;

[0057] 3. Dissolve 10g of polyvinyl alcohol 1788 in deionized water to configure a polyvinyl alcohol aqueous solution with a mass fraction of 13%, stir and heat in an 80° water bath for more than 8 hours until the solution is clear and tran...

Embodiment 3

[0063] 1. Put the 15 g of diamino-encapsulated polydimethylsiloxane in 150 ml of chloroform solution to form a polydimethylsiloxane solution with a mass fraction of 15%, and stir for 2 hours while maintaining the temperature at 5°; Add 0.35g of isophorone diisocyanate and 0.25g of 4'-methylene bis(phenyl isocyanate) dropwise and stir for 2 hours; add 20ml of methanol after fully reacting to remove excess isophorone diisocyanate, and let stand for 6 Hours until a white precipitate occurs; chloroform is evaporated above 80° to obtain a viscous solution of self-healing polydimethylsiloxane.

[0064] 2. Add the self-healing polydimethylsiloxane viscous solution dropwise onto the silicon substrate, and heat it to 80°C for two hours to cure;

[0065] 3. Dissolve 15g of polyvinyl alcohol 1788 in deionized water to configure a polyvinyl alcohol aqueous solution with a mass fraction of 15%. Stir and heat in a 90° water bath for more than 8 hours until the solution is clear and transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com