Wet etching process modeling method and manufacturing method of semiconductor device

A technology of wet etching and modeling method, applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve problems such as complex reaction mechanism, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

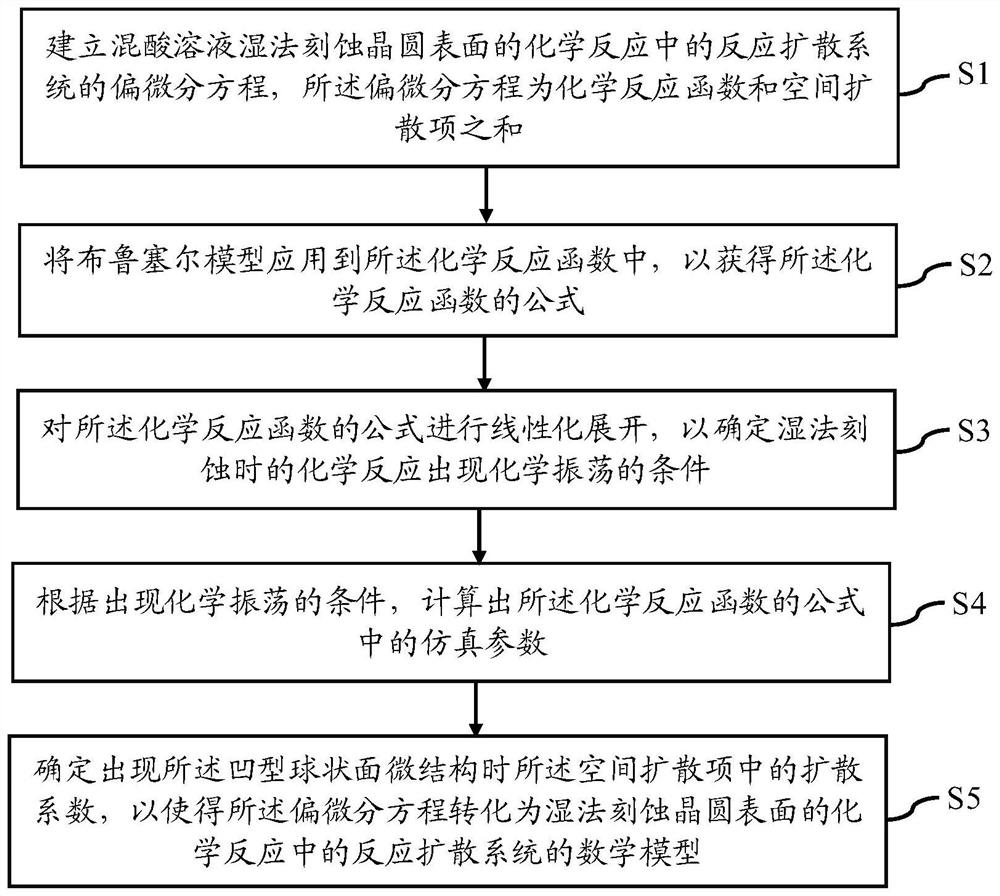

Method used

Image

Examples

Embodiment Construction

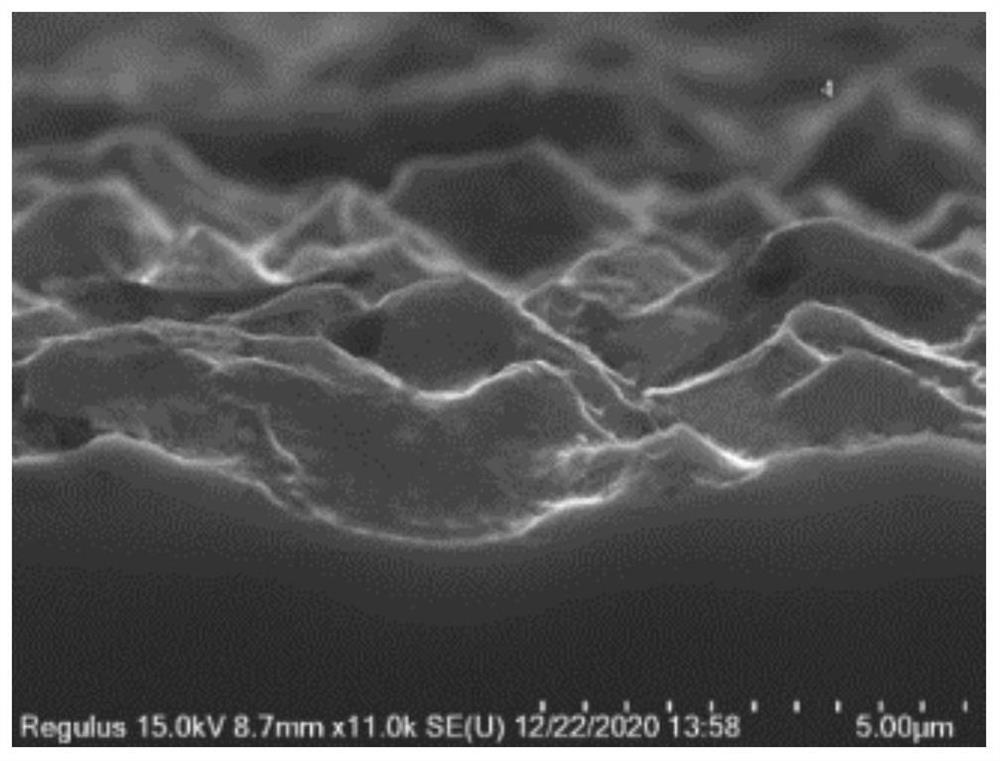

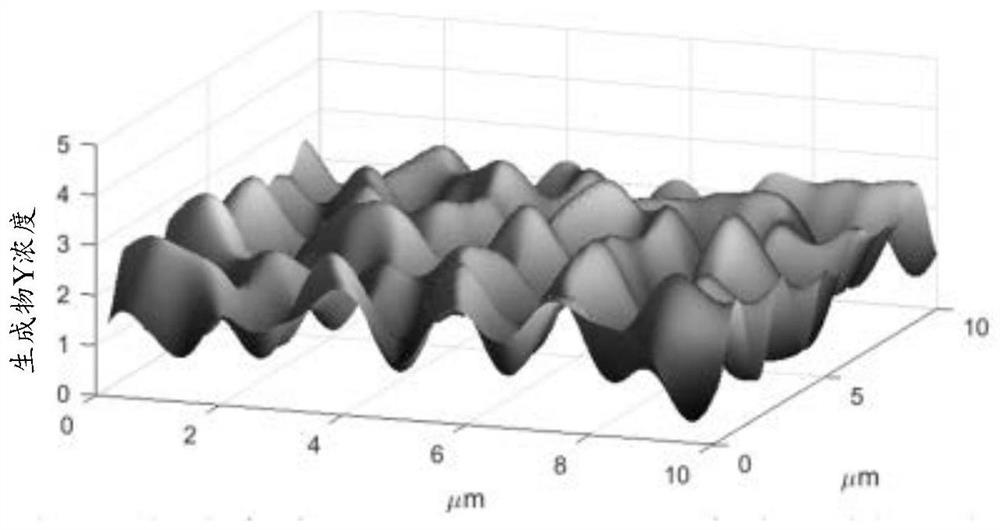

[0065] Take the wet etching of the silicon substrate on the back of the wafer with a mixed acid solution to form a concave spherical surface on the surface of the silicon substrate, thereby increasing the contact area with the metal electrode formed by sputtering metal to improve the overall adhesion of the interface , to explain the principle of wet etching to form a concave spherical surface:

[0066] Place the wafer in the acid tank of the cleaning machine or in the single wafer cleaning chamber to treat the silicon surface on the back of the wafer; during the reaction process, the temperature, the uniformity of mixed acid and the fluidity of the liquid are well controlled. In the system described above, reactants are transported from the main fluid to the boundary layer, diffuse to the silicon surface, and react, and products diffuse from the silicon surface to the boundary layer, and then transported to the main fluid.

[0067] At a set temperature, the microscopic moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com