Nano bionic enhanced gram-positive bacterium capturing-separating agent as well as preparation method and application thereof

A Gram-positive bacteria and nano-bionic technology, applied in the field of nano-magnetic separation, can solve the problems of bacterial lysis residue, complex equipment, and quality change of sterilization technology, and achieve the effect of rapid selectivity, simple operation, and broad application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

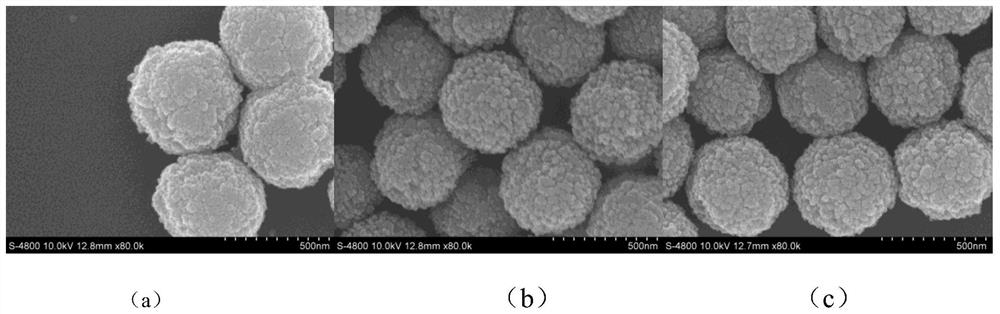

[0053] Step 1, synthesize ferroferromagnetic nanomaterials (Fe 3 o 4 NPs). Fully and uniformly dissolve 2.72g of ferric chloride hexahydrate and 7.20g of sodium acetate in 80mL of ethylene glycol. Add 0.25 g of polyacrylic acid, and fill with nitrogen for 2 hours under magnetic stirring. The mixture was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and the autoclave was heated to 120 °C for 2 hours, then heated to 200 °C for 10 hours. After the reaction kettle is naturally cooled to room temperature, the obtained black product is washed with absolute ethanol until the supernatant is clear and transparent, and vacuum-dried at 60°C to obtain Fe 3 o 4 Magnetic Nanomaterials.

[0054] Step 2, 200mg Fe 3 o 4 Sonicate in 200mL deionized water for 15min to disperse evenly, add 252mg oxalic acid to etch for 23min under mechanical stirring, wash the obtained material with deionized water, and vacuum dry to obtain viral vFe 3 o 4 Magnetic Nanomateri...

Embodiment 2

[0077] 1. Synthesis of Fe3O4 magnetic nanomaterials by solvothermal method 3 o 4 NPs). Fully and uniformly dissolve 2.72g of ferric chloride hexahydrate and 7.20g of sodium acetate in 80mL of ethylene glycol. Add 0.25 g of polyacrylic acid, and fill with nitrogen for 2 hours under magnetic stirring. The mixture was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and the autoclave was heated to 120 °C for 2 hours, then heated to 200 °C for 10 hours. After the reaction kettle is naturally cooled to room temperature, the obtained black product is washed with absolute ethanol until the supernatant is clear and transparent, and vacuum-dried at 60°C to obtain Fe 3 o 4 Magnetic Nanomaterials.

[0078] 2. Sonicate 200mg in 200mL deionized water for 15min to disperse evenly, Fe 3 o 4 The mass ratio to deionized water is 1:1; add 252 mg oxalic acid to the dispersion under mechanical stirring for 25 min, Fe 3 o 4 The mass ratio of oxalic acid to oxalic...

Embodiment 3

[0080] 1. Synthesis of Fe3O4 magnetic nanomaterials by solvothermal method 3 o 4 NPs). Fully and uniformly dissolve 2.72g of ferric chloride hexahydrate and 7.20g of sodium acetate in 80mL of ethylene glycol. Add 0.25 g of polyacrylic acid, and fill with nitrogen for 2 hours under magnetic stirring. The mixture was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and the autoclave was heated to 110°C for 2 hours, then heated to 190°C for 10 hours. After the reaction kettle is naturally cooled to room temperature, the obtained black product is washed with absolute ethanol until the supernatant is clear and transparent, and vacuum-dried at 60°C to obtain Fe 3 o 4 magnetic nanomaterials.

[0081] 2. Sonicate 200mg in 200mL deionized water for 15min to disperse evenly, Fe 3 o 4 The mass ratio to deionized water is 1:1; add 252 mg oxalic acid to the dispersion under mechanical stirring for 22 min, Fe 3 o 4 The mass ratio of oxalic acid to oxalic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com