Colchicine soluble microneedle patch and preparation method thereof

A technology of colchicine and micro-needle stickers, applied in sheet delivery, pharmaceutical formulations, organic active ingredients, etc., can solve the problems of unloaded colchicine research and patents, complex raw materials, slow onset time, etc. The effect of microneedle drug loading, bioavailability improvement, and elimination of bubble interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1 (preparation and effective puncture skin)

[0065] 1. Preparation of a soluble microneedle patch loaded with fluorescent substances

[0066] Preparation:

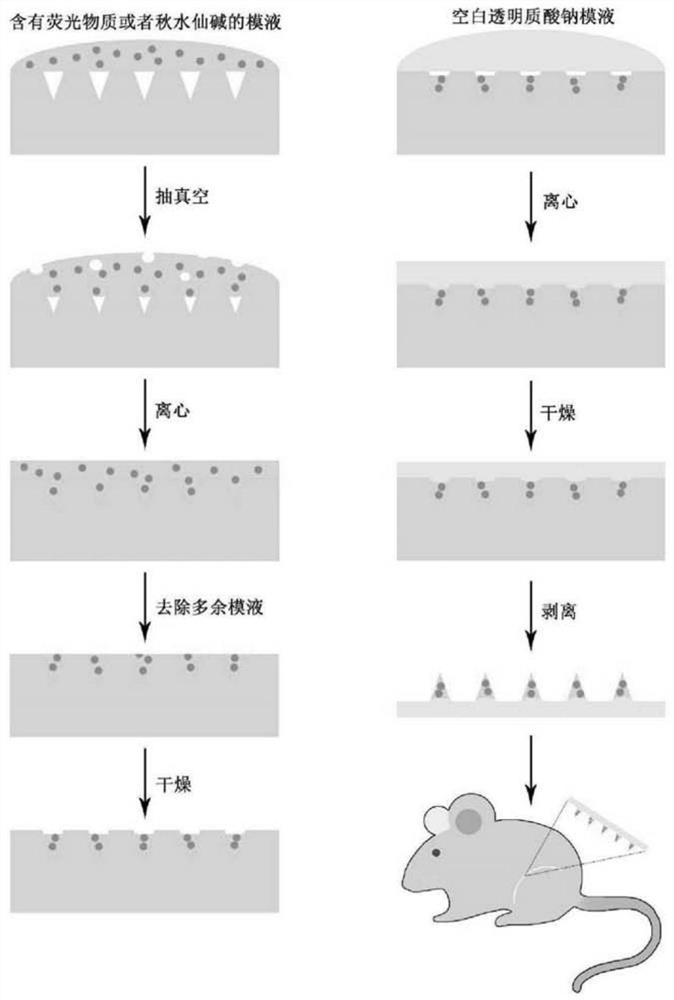

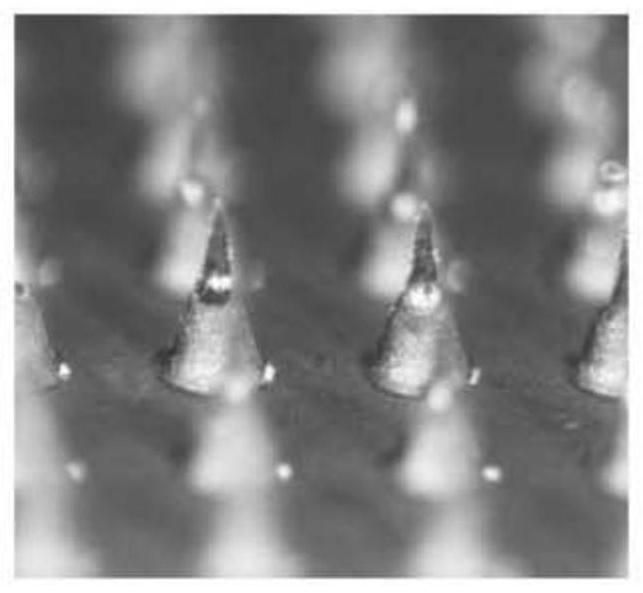

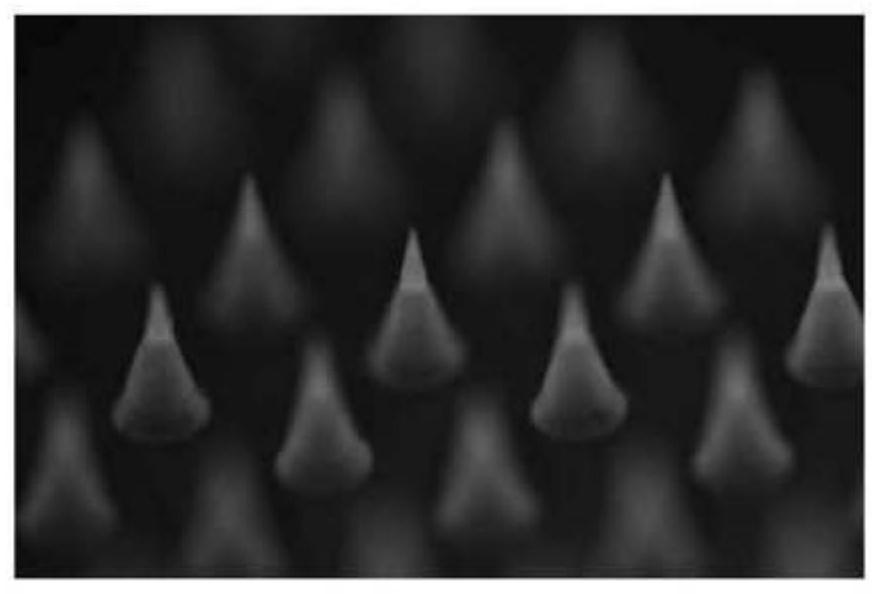

[0067] Add a magnetic stirrer in double distilled water and stir at 1000 rpm, and vacuumize at -0.1 MPa for 30 min. Add 320 mg of sodium hyaluronate (HA) and 8 mg of fluorescent substance sulforhodamine B (SRhB) into 8 mL of double-distilled water, and stir at room temperature at 400 rpm for 7 hours. Take 500μL of SRhB / HA mold solution and add it into the mold, vacuumize for 30min, and centrifuge at 3000rpm / 20min. Then add 300μL of SRhB / HA mold solution, vacuumize and centrifuge at 3000rpm / 10min. Remove excess mold liquid on the surface of the mold, centrifuge again at 3000rpm / 10min, and dry in an oven at 45°C for 1 hour.

[0068] Add 1.3mL blank HA mold liquid (concentration 0.04g / mL) to the mold with microneedle array, centrifuge at 3000rpm / 10min, dry at 45°C for 9h, peel off the microneedle from t...

Embodiment 2

[0075] Embodiment 2 (preparation and treatment on animal model)

[0076] 1. Preparation of a dissolvable microneedle patch loaded with colchicine

[0077] Add a magnetic stirrer in double distilled water and stir at 1000 rpm, and vacuumize at -0.1 MPa for 30 min. Add 320mg of sodium hyaluronate HA and 250mg of colchicine (Col) (the mass ratio of the two is 1.28:1) into 8mL of double-distilled water, and stir at room temperature at 400rpm for 7 hours. Take 500μL of Col / HA mold solution and add it into the mold, vacuumize for 30min, and centrifuge at 3000rpm / 20min. Then add 300μL of Col / HA mold liquid, vacuumize and centrifuge at 3000rpm / 10min. Remove excess mold liquid on the surface of the mold, centrifuge again at 3000rpm / 10min, and dry in an oven at 45°C for 1 hour.

[0078] Add 1.3mL blank HA mold liquid (concentration 0.04g / ml) to the mold with microneedle array, centrifuge at 3000rpm / 10min, dry at 45°C for 9h, peel off the microneedle from the mold and stick it on medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com