Carbon nitride composite photocatalyst based on oxygen doping as well as preparation method and application thereof

A carbon nitride and composite light technology, applied in the directions of carbon monoxide, physical/chemical process catalysts, chemical instruments and methods, can solve the problems of cumbersome preparation process, waste of time, poor catalytic performance, etc., and achieve simple and easy post-processing, Excellent performance and improved carrier transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 5.0 mmol of 1,3,5-trichlorotriazine CC in 50 mL of acetonitrile containing 0.5 mmol of dicyandiamide DCNA, subject the mixture to ultrasonic stirring for 10 min, and then transfer to a 100 mL Teflon-lined autoclave In the sterilizer, the autoclave was sealed and subjected to hydrothermal reaction at 180 °C for 22 h, cooled to room temperature after the reaction, washed with distilled water and ethanol, and vacuum-dried at 60 °C for 12 h to obtain the oxygen-doped nitriding Carbon composite photocatalyst, denoted as O-CN- 0.1 , where 0.1 is the raw material molar ratio of DCNA and CC.

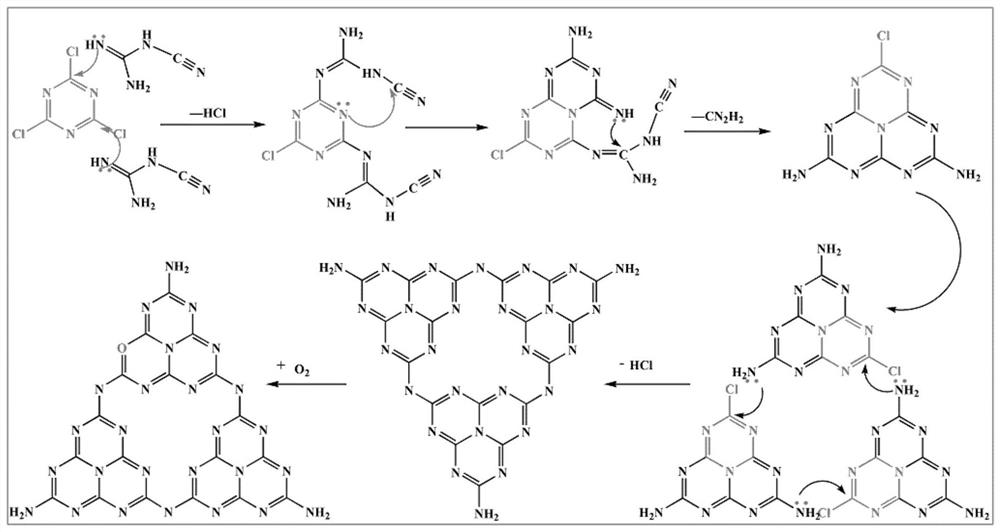

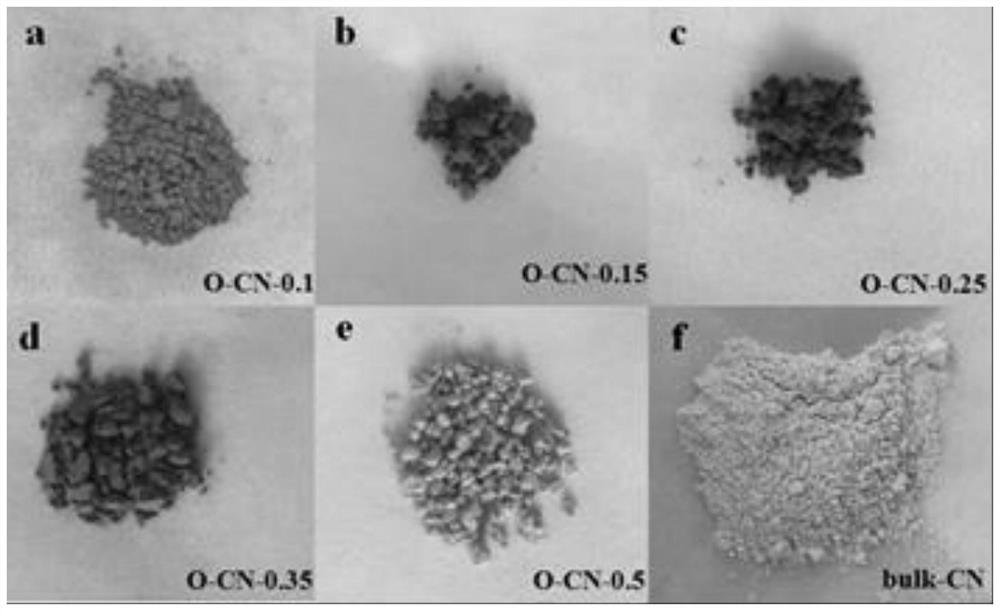

[0039] figure 1 Schematic diagram of the process based on oxygen-doped carbon nitride composite photocatalyst, figure 2 It is the physical picture of the carbon nitride composite photocatalyst based on oxygen doping. As can be seen from the figure, figure 2 O-CN- prepared in c 0.25 The red is the deepest, which indicates that the content of CC has a great influence on the ...

Embodiment 2

[0041] Dissolve 5.0 mmol of 1,3,5-trichlorotriazine CC in 50 mL of acetonitrile containing 0.75 mmol of dicyandiamide DCNA, subject the mixture to ultrasonic stirring for 20 min, and then transfer to a 100 mL Teflon-lined autoclave In a sterilizer, the autoclave was sealed and subjected to hydrothermal reaction at 200 °C for 24 h, cooled to room temperature after the reaction, washed with distilled water and ethanol, and vacuum-dried at 60 °C for 12 h to obtain the oxygen-doped nitriding Carbon composite photocatalyst, denoted as O-CN- 0.15 .

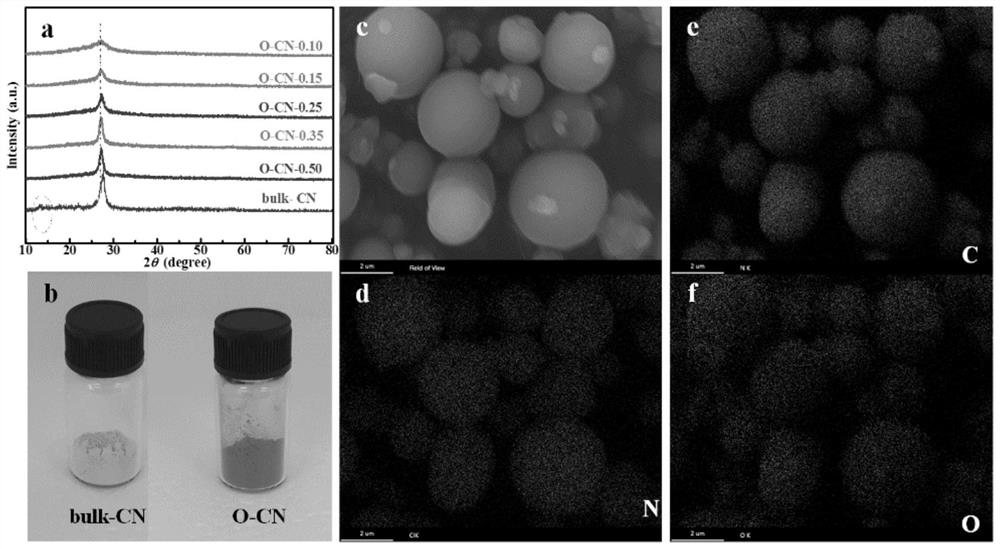

[0042] image 3 a is the XRD spectrum of prepared different samples, as can be seen from the figure, pure g-C 3 N 4 There are two distinct peaks at 13.0 and 27.4, corresponding to the (100) and (002) planes, respectively, the diffraction peak at 27.4° of O-CN-x shifts to lower diffraction angles, and the peak at 13.0° Significantly weakened, indicating that O was successfully embedded in the CN lattice. This is because the electron...

Embodiment 3

[0044] Dissolve 5.0 mmol 1,3,5-trichlorotriazine CC in 50 mL acetonitrile containing 1.25 mmol dicyandiamide DCNA, subject the mixture to ultrasonic stirring for 20 min, and then transfer to a 100 mL polytetrafluoroethylene-lined autoclave In a sterilizer, hydrothermally reacted at 200 °C for 24 h, cooled to room temperature after the reaction, washed with distilled water and ethanol and dried in vacuum at 60 °C for 12 h to obtain the oxygen-doped carbon nitride composite photocatalyst, denoted as O -CN- 0.25 .

[0045] Figure 4 a is pure g-C 3 N 4 and O-CN- 0.25 The XPS figure, it can be seen from the figure that pure g-C 3 N 4 and O-CN- 0.25 The elements C, N and O can be detected in all, but O-CN- 0.25 The O 1s peak intensity of the O 1s is significantly higher than that of pure g-C 3 N 4 , which shows that O-CN- 0.25 Surface O atoms are more abundant. Figure 4 b is O-CN- 0.25 It can be seen from the figure that the peaks at 284.6 eV, 286.8 eV and 288.9 eV ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com