Low-density high-strength tempered glass for bathroom and preparation method of low-density high-strength tempered glass

A tempered glass, high-strength technology, used in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of tempered glass bursting, serrated edges, damage and loss, etc., to isolate moisture, reduce glass density, The effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

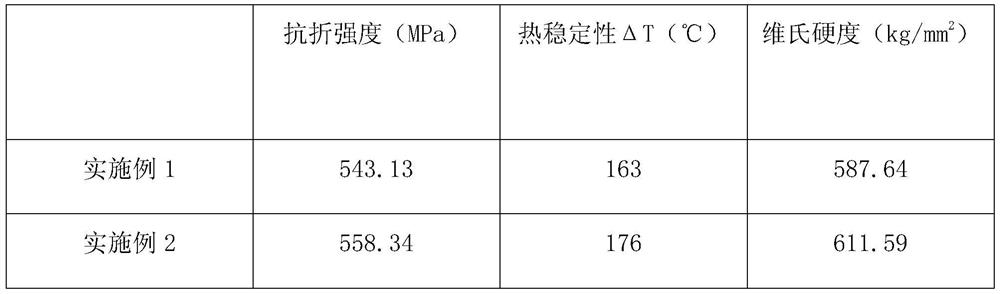

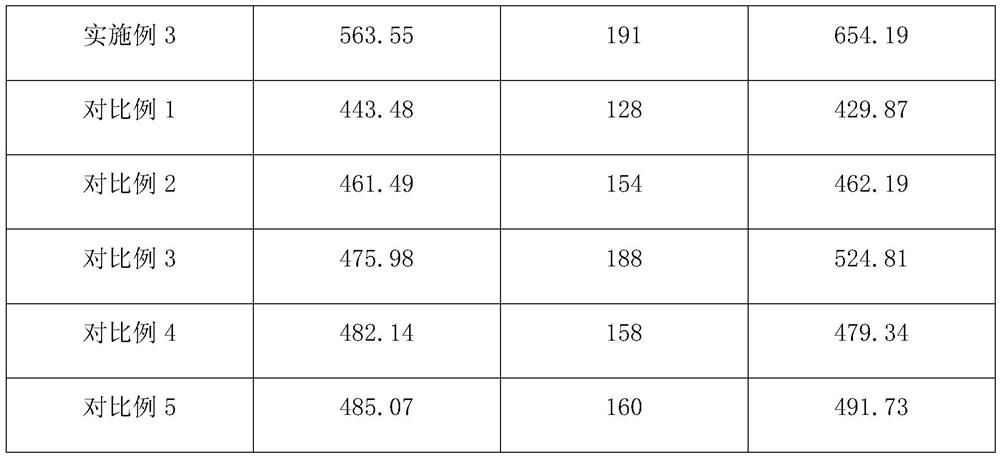

Embodiment 1

[0054] A method for preparing low-density high-strength tempered glass for bathroom, comprising the following steps:

[0055] S1: Smelting raw materials to obtain molten glass:

[0056] (1) Put 30 parts of quartz sand, 10 parts of borax, 25 parts of sodium oxide, 1 part of potassium oxide, and 1.5 parts of lithium oxide in a ball mill, grind for 20 minutes, place in an oven, dry at 60°C for 20 minutes, and place in a ball mill , grind for 40min to obtain mixture A powder;

[0057] (2) Put 2 parts of magnesium oxide, 3 parts of calcium oxide, and 12 parts of aluminum oxide in a ball mill, and grind for 35 minutes to obtain mixture B powder;

[0058] (3) Put 55 parts of waste glass and 0.5 parts of sodium chloride in a silicon-molybdenum furnace, heat up to 950°C at a rate of 3°C / min, keep it warm for 40min, add powder of mixture B, and heat up to 950°C at a rate of 2°C / min Stir at 1350°C for 10min, keep warm for 1h, add the powder of mixture A, raise the temperature to 1650°C...

Embodiment 2

[0069] A method for preparing low-density high-strength tempered glass for bathroom, comprising the following steps:

[0070] S1: Smelting raw materials to obtain molten glass:

[0071] (1) Put 35 parts of quartz sand, 13 parts of borax, 30 parts of sodium oxide, 2 parts of potassium oxide, and 2.5 parts of lithium oxide in a ball mill, grind for 25 minutes, place in an oven, dry at 60°C for 20 minutes, and place in a ball mill , grind for 50min to obtain mixture A powder;

[0072] (2) 4 parts of magnesium oxide, 4 parts of calcium oxide, and 14 parts of aluminum oxide were placed in a ball mill, and ground for 40 minutes to obtain mixture B powder;

[0073] (3) Put 50 parts of waste glass and 0.7 parts of sodium chloride in a silicon-molybdenum furnace, raise the temperature to 950°C at a rate of 3°C / min, keep it warm for 40min, add powder of mixture B, and heat up to 950°C at a rate of 2°C / min Stir at 1350°C for 10min, keep warm for 1h, add the powder of mixture A, raise t...

Embodiment 3

[0084] A method for preparing low-density high-strength tempered glass for bathroom, comprising the following steps:

[0085] S1: Smelting raw materials to obtain molten glass:

[0086] (1) Put 40 parts of quartz sand, 15 parts of borax, 35 parts of sodium oxide, 3 parts of potassium oxide, and 3 parts of lithium oxide in a ball mill, grind for 30 minutes, place in an oven, dry at 60°C for 20 minutes, and place in a ball mill , grind for 60min to obtain mixture A powder;

[0087] (2) 6 parts of magnesium oxide, 5 parts of calcium oxide, and 16 parts of aluminum oxide were placed in a ball mill, and ground for 45 minutes to obtain mixture B powder;

[0088] (3) Put 45 parts of waste glass and 0.9 parts of sodium chloride in a silicon-molybdenum furnace, raise the temperature to 950°C at a rate of 3°C / min, keep it warm for 40min, add powder of mixture B, and heat up to 950°C at a rate of 2°C / min Stir at 1350°C for 10min, keep warm for 1h, add the powder of mixture A, raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com