A kind of polyurethane with pH response and self-healing properties and preparation method thereof

A self-healing, polyurethane material technology, applied in the field of polymer materials to achieve the effect of improving damage recovery and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

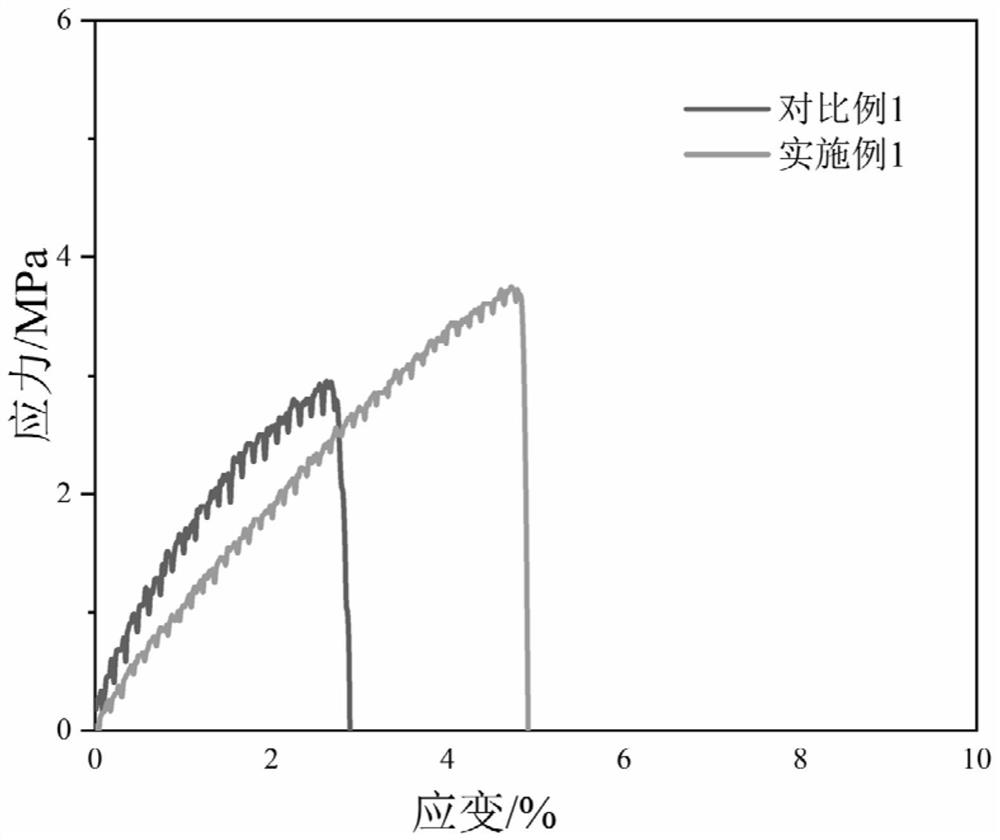

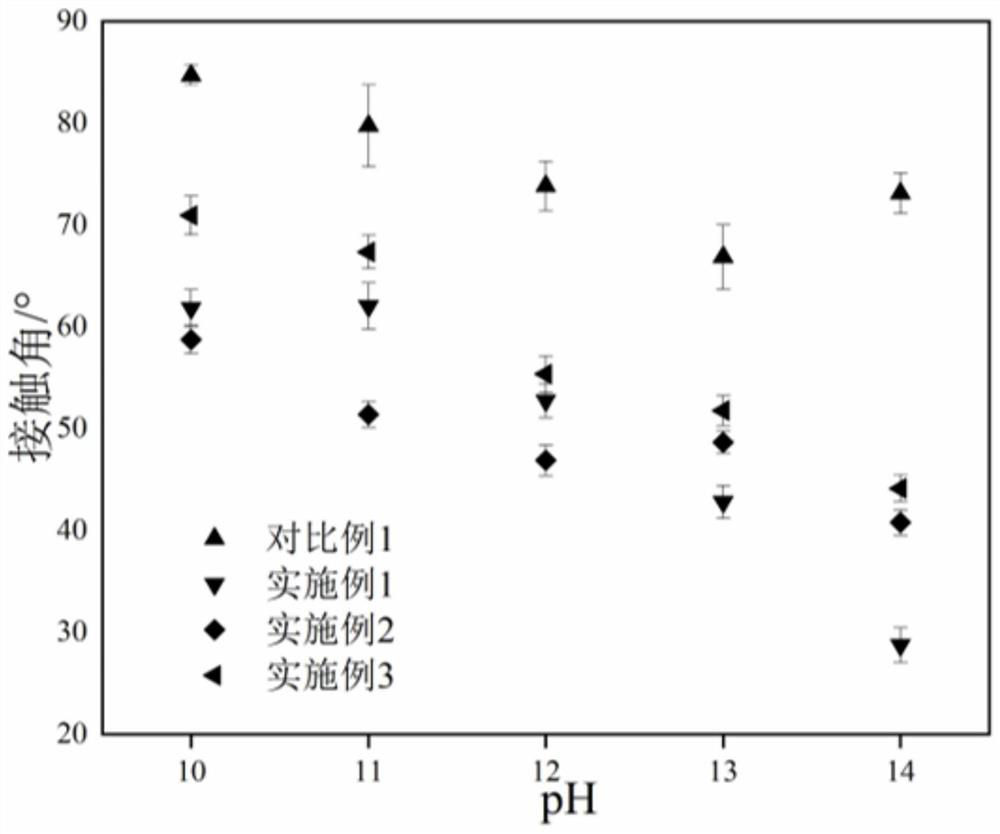

Embodiment 1

[0040] The present embodiment adopts the following raw materials:

[0041] 20g polycaprolactone diol (Mn~2000)

[0042] 160mL Tetrahydrofuran (THF)

[0043] 0.04g Dibutyltin dilaurate (DBTDL)

[0044] 0.856g Bis(2-hydroxyethyl)disulfide (SS)

[0045] 0.7408g 2,2-Dimethylolbutyric acid (DMBA)

[0046] 3.383g hexamethylene diisocyanate (HDI)

[0047] The preparation method of the present embodiment is:

[0048]In a three-necked flask equipped with an electric stirrer, a condenser tube and a vacuum tailpiece, polycaprolactone diol was added, and after vacuum dehydration at 110-120 °C for 2 hours, the temperature was lowered to about 60 °C, and HDI and an appropriate amount of tetrahydrofuran were added. Under nitrogen protection, the reaction was stirred at 60° C. for 1 hour to obtain a prepolymer. Add 0.856g bis(2-hydroxyethyl) disulfide (SS) and 0.7408g 2,2-dimethylolbutyric acid (DMBA) to the prepolymer to continue the reaction until the isocyanate is consumed completely...

Embodiment 2

[0073] The present embodiment adopts the following raw materials:

[0074] 10g polycaprolactone diol (Mn~1000)

[0075] 160mL N,N-Dimethylformamide (DMF)

[0076] 0.04g Dibutyltin dilaurate (DBTDL)

[0077] 0.8569g Bis(2-hydroxyethyl)disulfide (SS)

[0078] 0.7408g 2,2-Dimethylolbutyric acid (DMBA)

[0079] 3.3837g hexamethylene diisocyanate (HDI)

[0080] The preparation method of the present embodiment is:

[0081] In a three-necked flask equipped with an electric stirrer, a condenser tube and a vacuum tailpiece, polycaprolactone diol was added, and after vacuum dehydration at 110-120°C for 2 hours, the temperature was lowered to about 60°C, and HDI and an appropriate amount of N,N were added. -Dimethylformamide, stirred and reacted at 60°C for 1 hour under nitrogen protection to obtain a prepolymer. Add 0.856g bis(2-hydroxyethyl) disulfide (SS) and 0.7408g 2,2-dimethylolbutyric acid (DMBA) to the prepolymer to continue the reaction until the isocyanate is completely c...

Embodiment 3

[0097] The present embodiment adopts the following raw materials:

[0098] 10.6g polycaprolactone diol (Mn~530)

[0099] 160mL N,N-Dimethylformamide (DMF)

[0100] 0.04g Dibutyltin dilaurate (DBTDL)

[0101] 1.7138g Bis(2-hydroxyethyl)disulfide (SS)

[0102] 1.4966g 2,2-Dimethylolbutyric acid (DMBA)

[0103] 6.9654g hexamethylene diisocyanate (HDI)

[0104] The preparation method of the present embodiment is:

[0105] In a three-necked flask equipped with an electric stirrer, a condenser tube and a vacuum tailpiece, polycaprolactone diol was added, and after vacuum dehydration at 110-120°C for 2 hours, the temperature was lowered to about 60°C, and HDI and an appropriate amount of N,N were added. - Dimethylformamide, stirred and reacted at 60° C. for 1 hour under nitrogen protection to obtain a prepolymer. Add 0.856g bis(2-hydroxyethyl) disulfide (SS) and 0.7408g 2,2-dimethylolbutyric acid (DMBA) to the prepolymer to continue the reaction until the isocyanate is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com