System and method for purifying high-temperature household garbage pyrolysis oil gas

A technology for pyrolysis of oil and gas and high-temperature life, applied in chemical instruments and methods, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of secondary generation of dioxin, blockage of corrosion equipment pipelines, etc., to reduce corrosion, Improve the calorific value, ensure the effect of stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

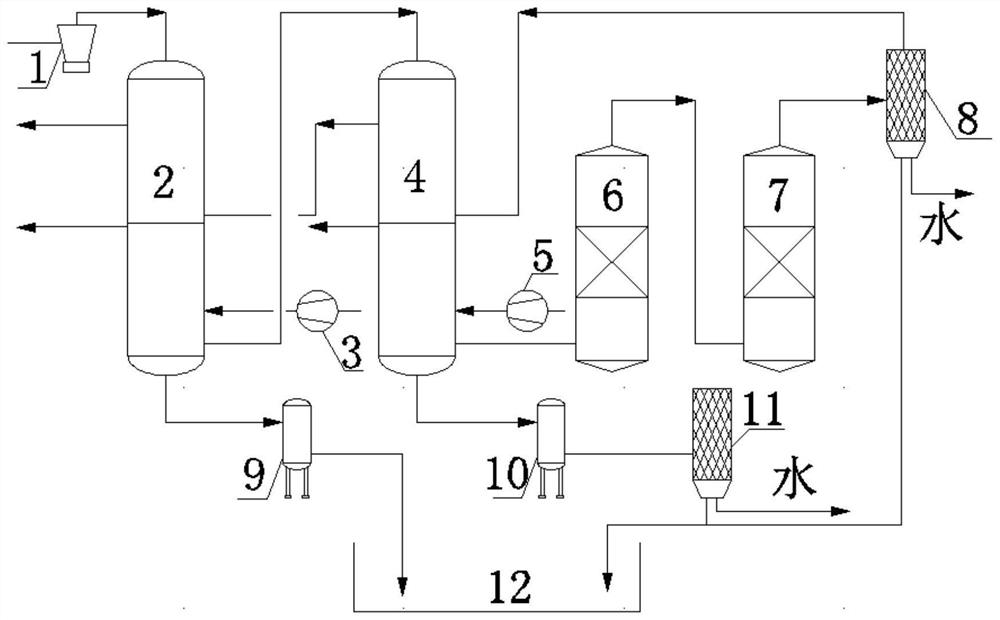

[0036] The system and method for pyrolyzing oil and gas purification of high-temperature domestic waste according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Such as figure 1 As shown, a purification system for pyrolysis oil and gas of high-temperature domestic waste of the present invention comprises a cyclone dust collector 1, a decoking cooler A2, a fan A3, a decoking cooler B4, a fan B5, a water washing tower 6, an alkali washing tower 7, Tar coalescer A8, tar filter A9, tar filter B10, tar coalescer B11 and tar storage tank 12;

[0038] Among them, the pyrolysis gas first enters the cyclone dust collector 1, the top of the cyclone dust collector 1 is connected to the top of the decoking cooler A2, the bottom of the decoking cooler A2 is connected to the upper part of the tar filter A9, and the lower part of the tar filter A9 is connected to to the tar storage tank 12;

[0039]The bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com