Monocrystalline silicon growth control process

A technology of growth control and monocrystalline silicon, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems affecting the production efficiency and production quality of monocrystalline silicon, low coaxiality, troublesome calibration work, etc., to achieve The effects of improving production efficiency and quality, improving coaxiality, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

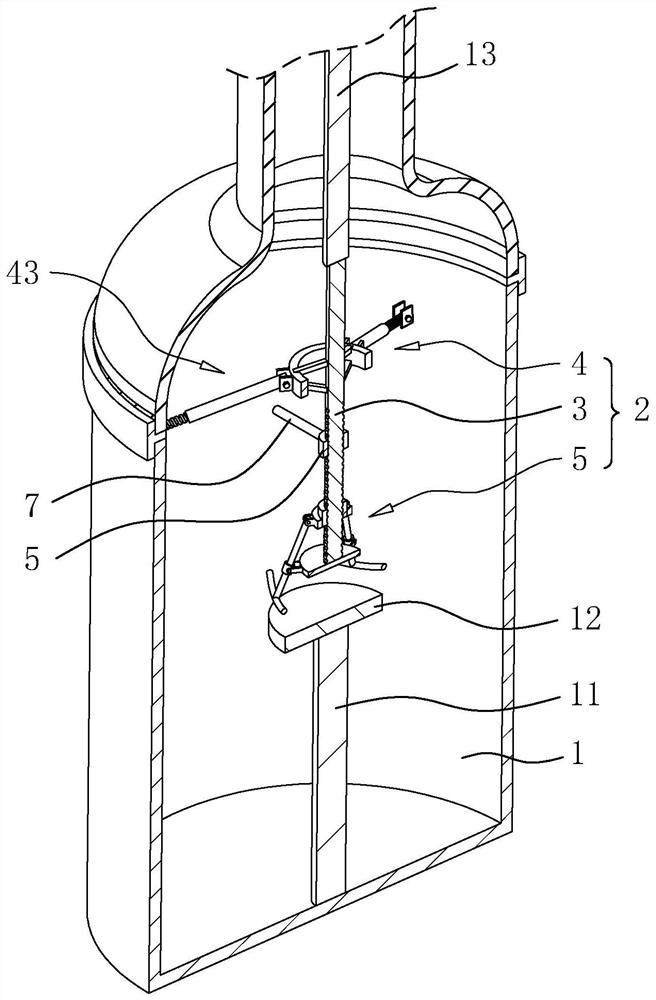

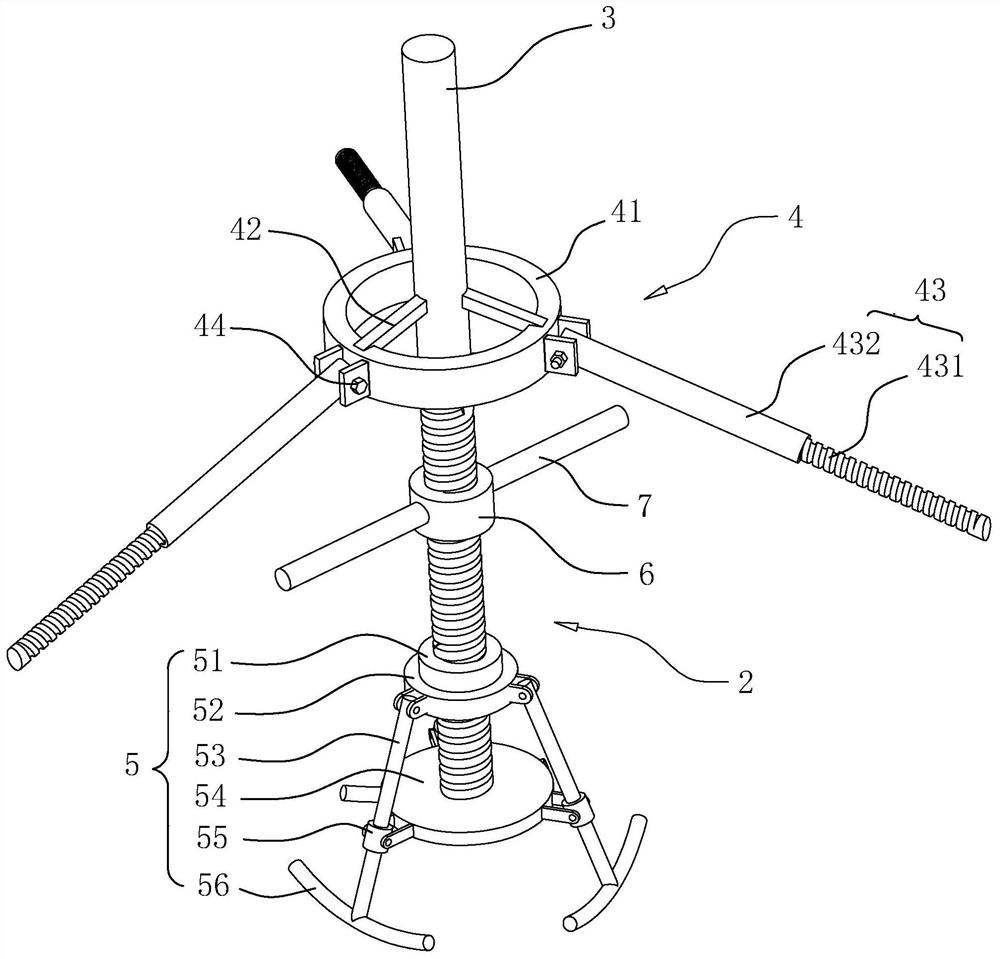

[0042] The following is attached Figure 1-2 The application is described in further detail.

[0043] The embodiment of the present application discloses a single crystal silicon growth control process. Single crystal silicon growth control process, the specific steps are as follows:

[0044] S1: A magnetic field device is erected outside the furnace tube 1 of the single crystal furnace, and a magnetic field is applied to the inside of the furnace tube 1 . According to different magnetic field devices, the magnetic field can be set as a transverse magnetic field, a hook magnetic field or a rotating magnetic field, which is used to suppress the heat convection phenomenon of the solution inside the furnace barrel 1, thereby improving the crystallization quality of single crystal silicon.

[0045] S2: charging;

[0046] S21: Refer to figure 1 , a coaxial alignment device 2 is arranged in the furnace drum 1, a graphite crucible is installed in the furnace drum 1, and a quartz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com