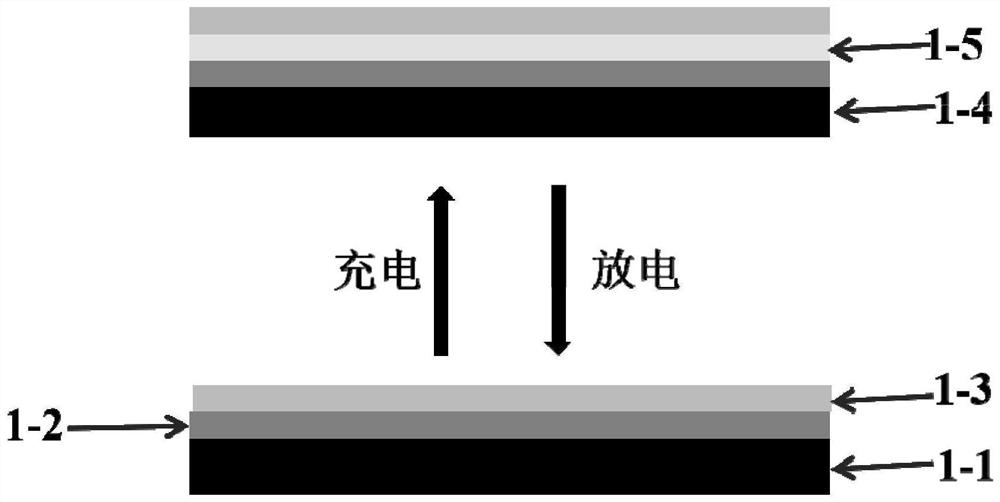

All-solid-state lithium battery and preparation method thereof

A lithium battery, all-solid-state technology, applied in the field of all-solid-state lithium batteries and their preparation, can solve problems such as reducing battery safety, and achieve the effects of improving energy density and safety, improving cycle life, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

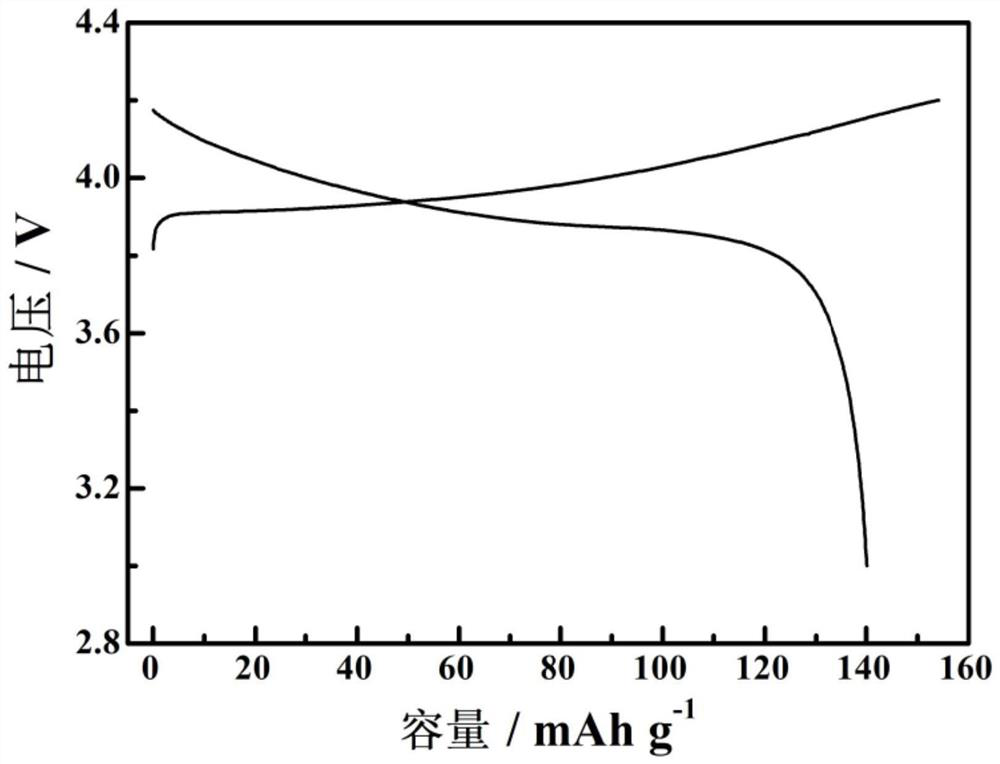

Embodiment 1

[0108] Lithium bistrifluoromethanesulfonylimide, lithium difluorooxalate borate and lithium hexafluorophosphate (molar ratio 8:2:0.5), polyethylene glycol methyl ether methyl methacrylate monomer and polyethylene glycol diglycidyl ether The monomer (the molar ratio of the two monomers is 4:1), the azobisisobutyronitrile initiator is mixed and fully stirred to obtain a polymer electrolyte precursor, wherein the weight ratio of the lithium salt to the polymer monomer is 1: 7. The weight ratio of initiator and polymer monomer is 1:100; LiCoO with a weight ratio of 4:100 2 Powder and Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The ceramic precursor powder is uniformly mixed, and then physically fused by a fusion machine, and heat-treated (air atmosphere, 700 ° C, 4 hours), and the surface is coated with Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 LiCoO 2 powder; the coated LiCoO 2 Powder, conductive agent carbon black and polyvinylidene fluoride binder are mixed in N-methylpyrrolidone, and LiCoO...

Embodiment 2

[0124] Lithium trifluoromethanesulfonate, lithium bisoxalate borate and lithium hexafluorophosphate (molar ratio 3:1:0.2), tetraethylene glycol dimethacrylate monomer and 1,4-butanediol glycidyl ether monomer (two The molar ratio of the first monomer is 3:1), the azobisisobutyronitrile initiator is mixed and fully stirred uniformly to obtain the polymer electrolyte precursor, wherein the weight ratio of the lithium salt to the polymer monomer is 1:4, and the initiator The weight ratio of the polymer monomer to the polymer monomer is 1:100; the LiNi with a weight ratio of 4:100 0.7 co0.15 mn 0.15 o 2 Powder and Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The ceramic precursor powder is uniformly mixed, and then physically fused by a fusion machine, and heat-treated (air atmosphere, 700 ° C, 4 hours), and the surface is coated with Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 LiNi 0.7 co 0.15 mn 0.15 o 2 powder; the coated LiNi 0.7 co 0.15 mn 0.15 o 2 Powder, conductive agent and polyvi...

Embodiment 3

[0127] Lithium bisfluorosulfonyl imide, lithium difluorooxalate borate and lithium hexafluorophosphate (molar ratio 5:1:0.3), 2-acrylic acid-(5-ethyl-1,3-dioxan-5-yl ) methyl ester monomer and polypropylene glycol diglycidyl ether monomer (the molar ratio of the two monomers is 5:1), azobisisobutyronitrile initiator is mixed and fully stirred to obtain a polymer electrolyte precursor, wherein The weight ratio of lithium salt and polymer monomer is 1:10, and the weight ratio of initiator and polymer monomer is 1:100; LiNi with a weight ratio of 4:100 0.6 co 0.2 mn 0.2 o 2 Powder and Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The ceramic precursor powder is evenly mixed, and the fusion machine is used for physical fusion and heat treatment (air atmosphere, 700 ° C, 4 hours), and the surface is coated with Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 LiNi 0.6 co 0.2 mn 0.2 o 2 powder; the coated LiNi 0.6 co 0.2 mn 0.2 o 2 Powder, conductive agent and polyvinylidene fluoride binder are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com