Active composition for improving skin barrier function and preparation method thereof

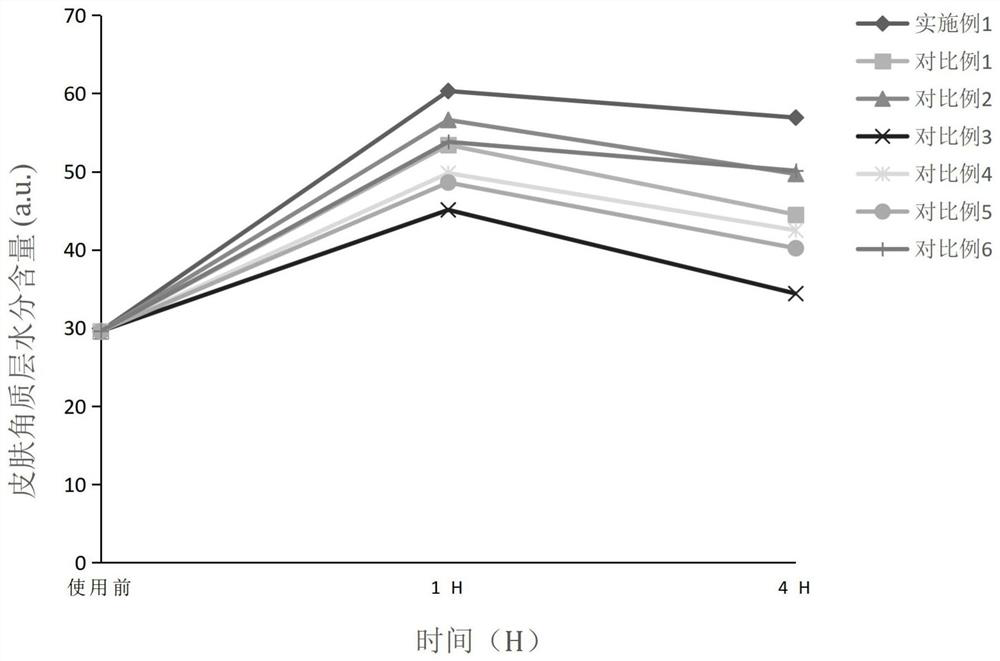

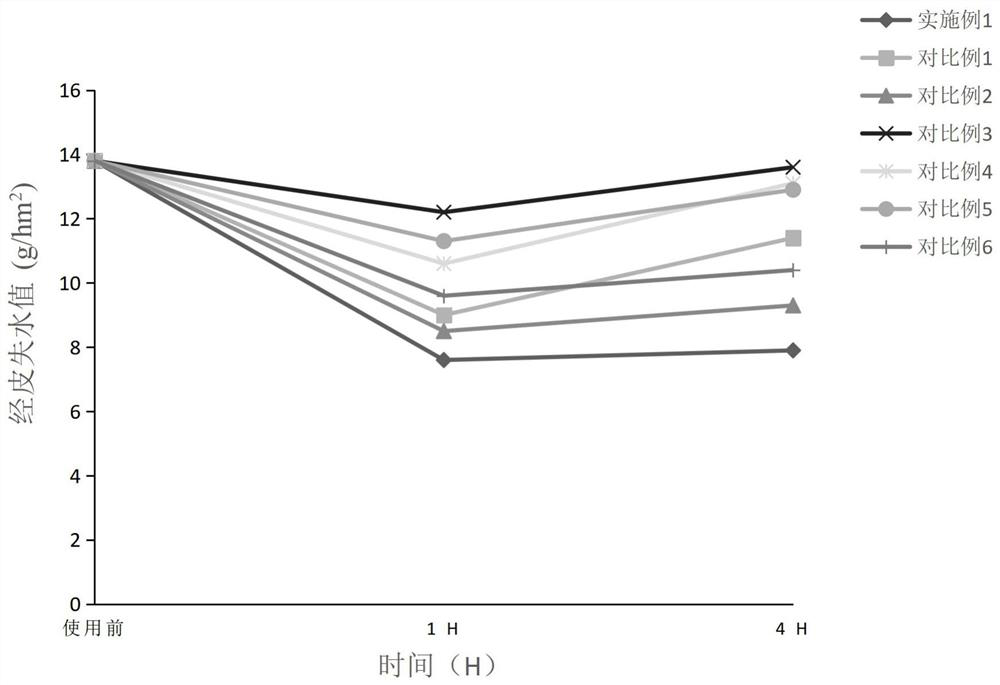

A technology for improving skin and composition, applied in the field of hand cream, which can solve the problems of easy infection by bacteria and fungi, damage of skin barrier function, rough and peeling skin, etc., so as to reduce transepidermal water loss and enhance long-term moisturizing effect, the effect of enhancing skin permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

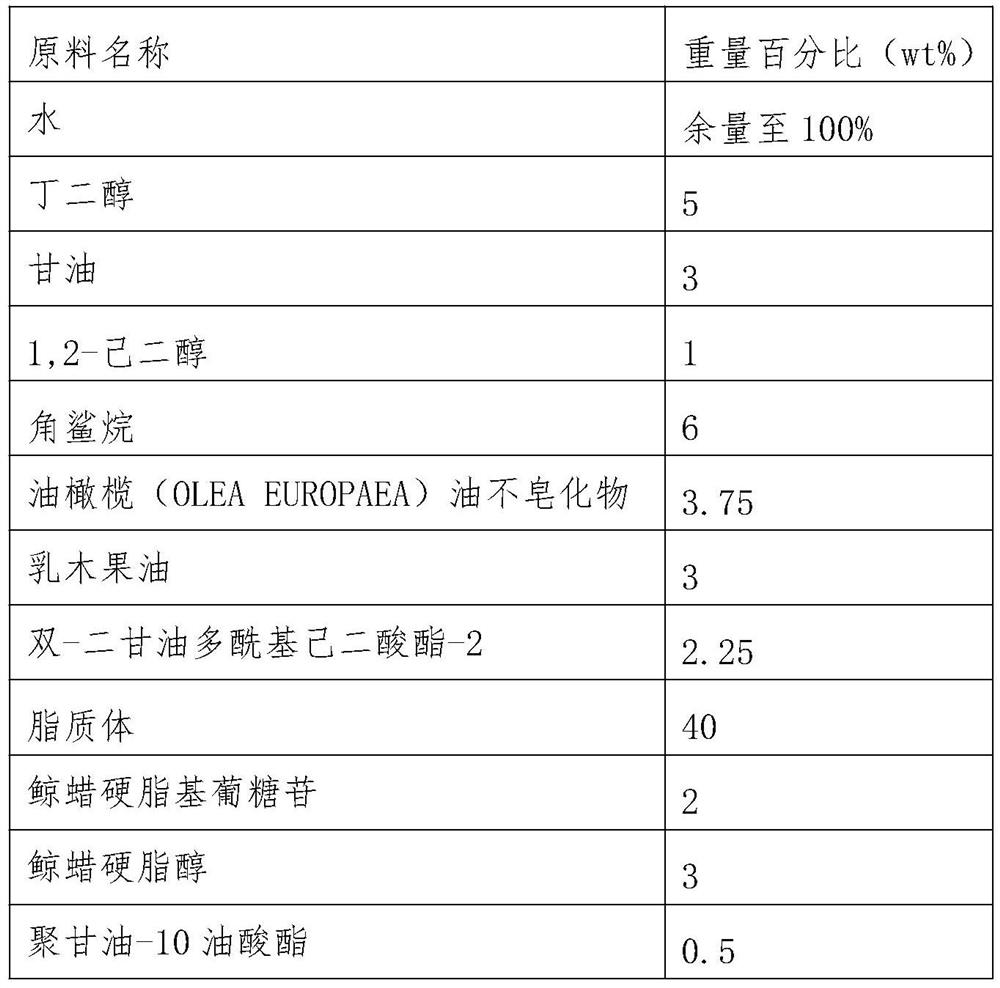

Embodiment 1

[0026] Preparation of liposomes: Dissolve 4 parts of hydrogenated lecithin, 2 parts of ceramide 3, and 2 parts of cholesterol in 10 parts of ethanol, heat to 80° C. as oil phase; 1 part of small molecule sodium hyaluronate (molecular weight 40,000 ), 1 part of hydroxyethylpiperazine ethanesulfonic acid, dissolved in 80 parts of deionized water, heated to 80 ° C as the water phase; the oil phase and the water phase were loaded into glass syringes, and the syringes passed through the microtube and the microfluidic Control chip connection, adjust the injection flow rate of the syringe pump (model WZ-50C2): the ratio of the volume flow rate of the water phase channel on both sides of the microfluidic chip to the volume flow rate of the central oil phase channel V 水相 / V 油相 =8, the injection flow rate of the central oil phase channel is set to 0.2mg / min, liposomes are collected at the outlet, diafiltration is used to remove ethanol, and sterilized by filtration with a 0.22 μm filter...

Embodiment 2

[0037] Preparation of liposomes: Dissolve 6 parts of hydrogenated lecithin, 3 parts of ceramide 3, and 2 parts of cholesterol in 9 parts of ethanol, heat to 90 ° C, as the oil phase; 1.5 parts of small molecule sodium hyaluronate (molecular weight 40,000 ), 1.5 parts of hydroxyethylpiperazine ethanesulfonic acid, dissolved in 80 parts of deionized water, heated to 90 ° C as the water phase; the oil phase and the water phase were loaded into glass syringes, and the syringes passed through the microtube and microfluidic Control chip connection, adjust the injection flow rate of the syringe pump (WZ-50C2): the ratio of the volume flow rate of the water phase channel on both sides of the microfluidic chip to the volume flow rate of the central oil phase channel V 水相 / V 油相 =10, the injection flow rate of the central oil phase channel was set at 0.4 mg / min, liposomes were collected at the outlet, ethanol was removed by diafiltration, and sterilized by filtration with a 0.22 μm filte...

Embodiment 3

[0042] Preparation of liposome: Dissolve 5 parts of hydrogenated lecithin, 3 parts of ceramide 3, and 2 parts of cholesterol in 10 parts of ethanol, heat to 80° C., as oil phase; 2 parts of small molecule sodium hyaluronate (molecular weight 40,000 ), 2 parts of hydroxyethylpiperazine ethanesulfonic acid, dissolved in 80 parts of deionized water, heated to 80 ° C as the water phase; the oil phase and the water phase were loaded into glass syringes, and the syringes passed through the microtube and the microfluidic Control chip connection, adjust the injection flow rate of the syringe pump (WZ-50C2): the ratio of the volume flow rate of the water phase channel on both sides of the microfluidic chip to the volume flow rate of the central oil phase channel V 水相 / V 油相 =6, the injection flow rate of the central oil phase channel was set at 0.3 mg / min, liposomes were collected at the outlet, ethanol was removed by diafiltration, and sterilized by filtration with a 0.22 μm filter mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com