Preparation method of anti-corrosion finger joint laminated board wood

A finger-jointed board and wood technology, which is applied in wood processing equipment, manufacturing tools, adhesive types, etc., can solve the problems of unstable structure and physical and chemical properties of finger-jointed boards, affecting indoor environmental quality, and large material loss, etc. , achieve the effect of reducing flammability risk, short curing time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing anti-corrosion finger-jointed wood, comprising the following steps:

[0033] S1: Drying and peeling the fresh Eucalyptus grandis logs, sawing them into spare sawn timber, and then drying them to a moisture content of 10%;

[0034] S2: Cut the spare sawn timber into finger-joints of the required size with fixed width and length, tenon the finger-joints with a tenoning machine, and then vertically join the tenoned finger-joints with a docking machine growth bar;

[0035] S3: Apply glue to the side of the finger-jointed strips, and use a jigsaw machine to splice the finger-joined strips in parallel to form a board. After the board is assembled, dry it to a moisture content of 8%;

[0036] S4: Sand and edge-cut the finger-joint board with a sander and a fine-cut saw; pack the qualified products into storage;

[0037] The adhesive used for gluing is prepared from raw materials including the following parts by weight: 300 parts of formaldehyde, 150 pa...

Embodiment 2

[0045] A method for preparing anti-corrosion finger-jointed wood, comprising the following steps:

[0046] S1: Drying and peeling the fresh Eucalyptus grandis log, sawing it into spare sawn timber, and then drying it to a moisture content of 11%;

[0047] S2: Cut the spare sawn timber into finger-joints of the required size with fixed width and length, tenon the finger-joints with a tenoning machine, and then vertically join the tenoned finger-joints with a docking machine growth bar;

[0048] S3: Apply glue to the side of the finger-jointed strips, and use a jigsaw machine to splice the finger-joined strips in parallel to form a board. After the board is assembled, dry it to a moisture content of 10%;

[0049] S4: Sand and edge-cut the finger-joint board with a sander and a fine-cut saw; pack the qualified products into storage;

[0050] The adhesive used for gluing is prepared from raw materials including the following parts by weight: 400 parts of formaldehyde, 250 parts ...

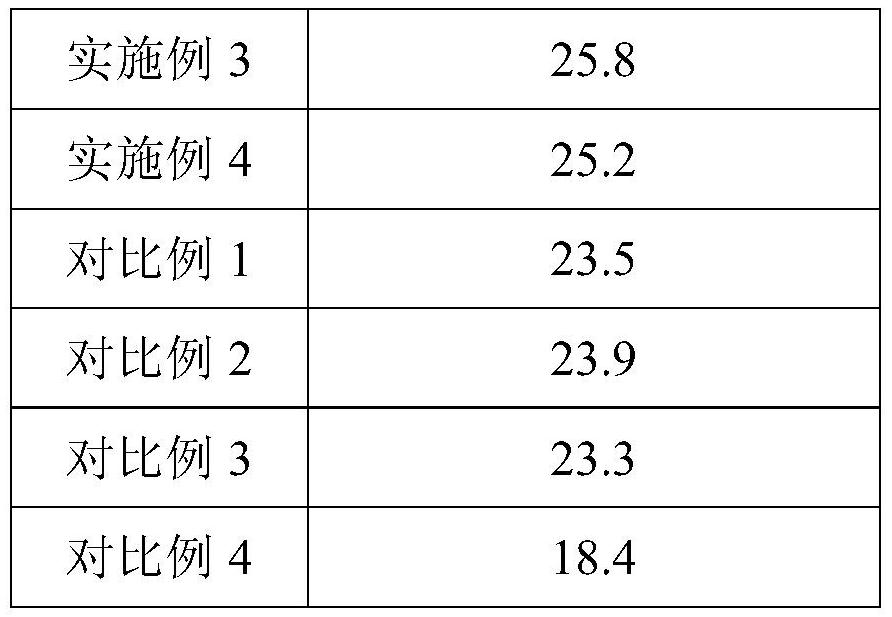

Embodiment 3

[0058] A method for preparing anti-corrosion finger-jointed wood, comprising the following steps:

[0059] S1: Drying and peeling the fresh Eucalyptus grandis log, sawing it into spare sawn timber, and then drying it to a moisture content of 12%;

[0060] S2: Cut the spare sawn timber into finger-joints of the required size with fixed width and length, tenon the finger-joints with a tenoning machine, and then vertically join the tenoned finger-joints with a docking machine growth bar;

[0061] S3: Apply glue to the side of the finger-jointed strips, and use a jigsaw machine to splice the finger-joined strips in parallel to form a board. After the board is assembled, dry it to a moisture content of 10%;

[0062] S4: Sand and edge-cut the finger-joint board with a sander and a fine-cut saw; pack the qualified products into storage;

[0063] The adhesive used for gluing is prepared from raw materials including the following parts by weight: 600 parts of formaldehyde, 220 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com