A kind of high melt index high modulus asphalt mixture additive and its preparation method and application

A kind of asphalt mixture, high modulus technology, applied in the direction of building insulation materials, building components, construction, etc., can solve the problems of unstable source of raw materials, poor product performance stability, high application cost, etc., achieve excellent melt dispersion, improve resistance Rutting performance, effect of improving low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

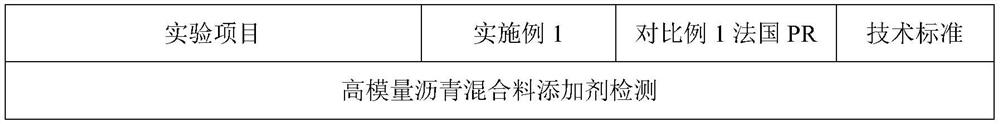

Embodiment 1

[0031] (1) First weigh 1000g of anti-rutting masterbatch, 100g of Xinjiang rock asphalt, 100g of high-melting index POE VM8380, 100g of high-density polyethylene HDPE, 1g of lubricant oleic acid amide, 2,5-dimethyl-2,5 Put 1 g of di-tert-butyl peroxide hexane into a high-speed mixer to stir the mixture rapidly, and release it after stirring for 5 minutes.

[0032] (2) Add the mixed materials in step (1) into the feeding hopper of the twin-screw extruder for extrusion and granulation. The temperature of the feed port is 80°C, the melting temperature is 200°C, and the die temperature is 140°C , the speed of the host machine is 200r / min, and the cutting speed is 1500r / min. After underwater granulation, the high-melting index and high modulus asphalt mixture additive 1 is obtained.

[0033] Application of high melting point high modulus asphalt mixture additive:

[0034] S1. Heat the base asphalt to 140°C, according to the EME-14 gradation, weigh a certain mass of aggregates in a...

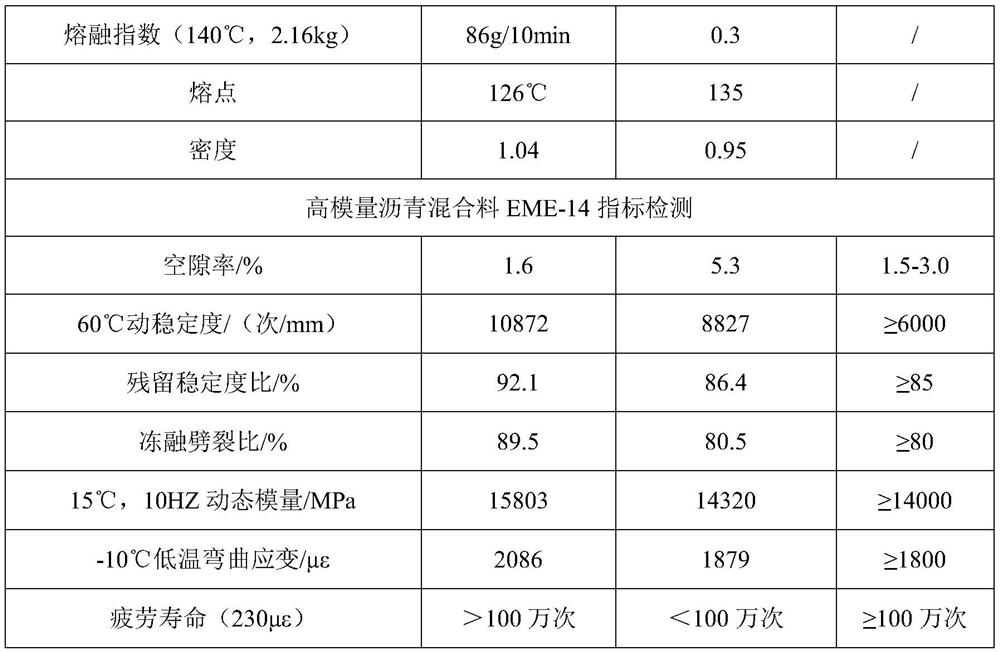

Embodiment 2

[0043] (1) First weigh 1000g of anti-rutting masterbatch, 150g of Xinjiang rock asphalt, 200g of high-melting index POE VM8780, 200g of high-density polyethylene HDPE, 2g of lubricant oleic acid amide, 2,5-dimethyl-2,5 3g of di-tert-butyl peroxide hexane is put into a high-speed mixer to stir the mixed material rapidly, and release after stirring for 5min.

[0044] (2) Add the mixed materials in step (1) into the feeding hopper of the twin-screw extruder for extrusion and granulation. The inlet temperature is 50°C, the melting temperature is 260°C, and the die temperature is 130°C. The rotation speed of the host machine is 300r / min, and the cutting speed is 2000r / min. After underwater granulation, the high-melt index and high modulus asphalt mixture additive 2 is obtained.

[0045] Application of high melting point high modulus asphalt mixture additive:

[0046] S1. Heat the base asphalt to 150°C, according to the EME-14 gradation, weigh a certain mass of aggregates in an exo...

Embodiment 3

[0053] (1) First weigh 1000g of anti-rutting masterbatch, 200g of North American rock asphalt, 150g of high-melting index POE VM8880, 150g of high-density polyethylene HDPE, 2g of lubricant erucamide, 2,5-dimethyl-2,5 Put 2 g of di-tert-butyl peroxide hexane into a high-speed mixer to stir the mixture rapidly, and release it after stirring for 5 minutes.

[0054] (2) Add the mixed materials in step (1) into the feeding hopper of the twin-screw extruder for extrusion and granulation. The inlet temperature is 70°C, the melting temperature is 240°C, and the die temperature is 120°C. The rotation speed of the host machine is 300r / min, and the cutting speed is 2500r / min. After underwater granulation, the high-melt index and high modulus asphalt mixture additive 3 is obtained.

[0055] Application of high melting point high modulus asphalt mixture additive:

[0056] S1. Heat the SBS modified asphalt to 150°C, according to the EME-14 gradation, weigh a certain quality of aggregate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com