Preparation method and application of copper-indium composite catalyst

A composite catalyst, copper indium technology, applied in the direction of electrodes, electrolytic organic production, electrolytic process, etc., can solve the problems of limiting the commercial application of copper-based catalysts, slow electron transfer kinetics, poor selectivity of specific products, etc., to achieve multi-reaction activity site, beneficial to adsorption, and the effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

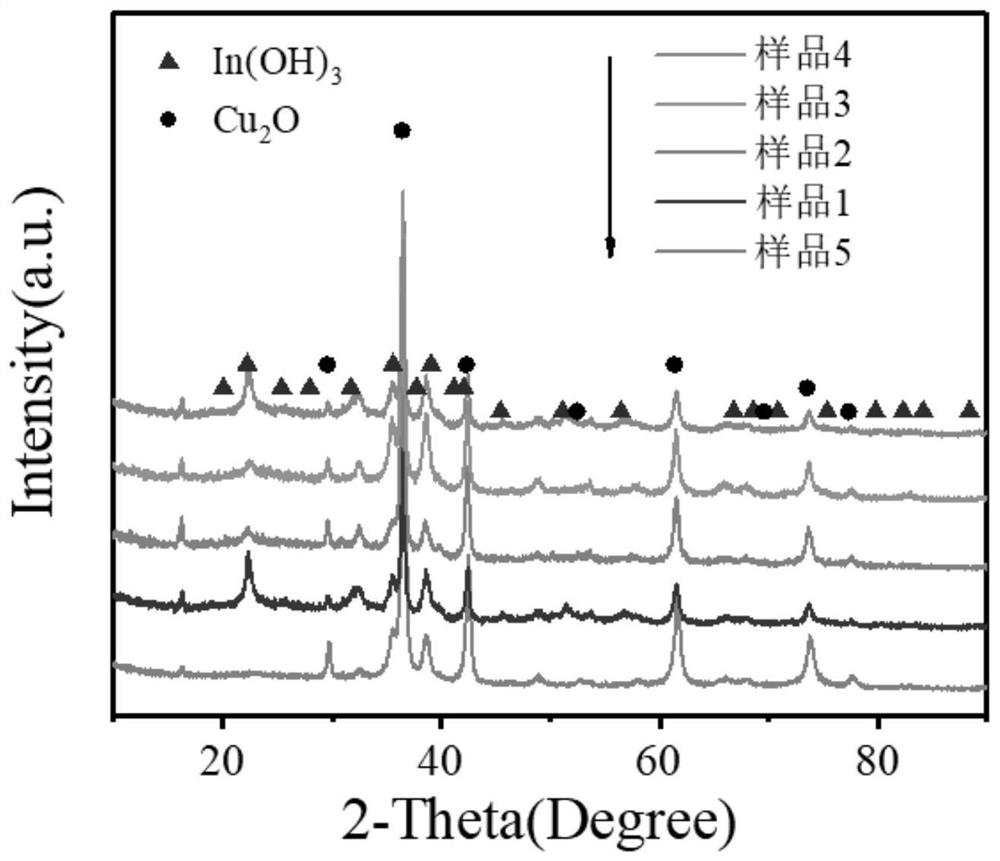

[0033] A preparation method of a copper-indium composite catalyst, specifically comprising the steps of:

[0034] (1) Weigh anhydrous indium chloride and copper chloride dihydrate with a raw material molar ratio of 1:5, wherein, anhydrous indium chloride InCl 3 0.221 g, copper chloride dihydrate CuCl 2 2H 2 O 0.852g, and placed in a container, add 100mL of deionized water, under normal temperature conditions, with a rotation speed of 400r / min, stir for 3min to dissolve, to obtain a mixed solution;

[0035] (2) Add 2.5mL of concentrated ammonia water with a concentration of 14M to the mixed solution in step (1), stir at room temperature at a speed of 800r / min for 2min, and mix well;

[0036] (3) Continue to dropwise add 10mL of sodium hydroxide solution with a concentration of 1M in the mixed solution, and stir for 10min at room temperature with a rotation speed of 800r / min;

[0037] (4) Finally, 1 mL of hydrazine solution was added dropwise to the mixed solution, and stirre...

Embodiment 2

[0040] A preparation method of a copper-indium composite catalyst, specifically comprising the steps of:

[0041] (1) Weigh anhydrous indium chloride and copper chloride dihydrate with a raw material molar ratio of 1:10, wherein anhydrous indium chloride InCl 3 0.111 g, copper chloride dihydrate CuCl 2 2H 2 O 0.852g, and placed in a container, add 100mL of deionized water, under normal temperature conditions, with a rotation speed of 400r / min, stir for 4min to dissolve, to obtain a mixed solution;

[0042] (2) Add 2.5mL of concentrated ammonia water with a concentration of 14M to the mixed solution in step (1), stir for 3min at room temperature at a speed of 800r / min, and mix well;

[0043] (3) Continue to add dropwise 10 mL of 1M sodium hydroxide solution in the mixed solution, and stir for 15 min at room temperature with a rotation speed of 800 r / min;

[0044] (4) Finally, 1 mL of hydrazine solution was added dropwise to the mixed solution, and stirred at room temperature...

Embodiment 3

[0047] A preparation method of a copper-indium composite catalyst, specifically comprising the steps of:

[0048] (1) Weigh anhydrous indium chloride and copper chloride dihydrate with a raw material molar ratio of 1:20, wherein anhydrous indium chloride InCl 3 0.055 g, copper chloride dihydrate CuCl 2 2H 2 O 0.852g, and placed in a container, add 100mL of deionized water, under normal temperature conditions, with a rotation speed of 400r / min, stir for 3min to dissolve, to obtain a mixed solution;

[0049] (2) Add 2.5mL of concentrated ammonia water with a concentration of 14M to the mixed solution in step (1), stir for 3min at room temperature at a speed of 800r / min, and mix well;

[0050] (3) Continue to dropwise add 12mL of sodium hydroxide solution with a concentration of 1M in the mixed solution, and stir for 15min at room temperature with a rotation speed of 800r / min;

[0051] (4) Finally, 1 mL of hydrazine solution was added dropwise to the mixed solution, and stirre...

PUM

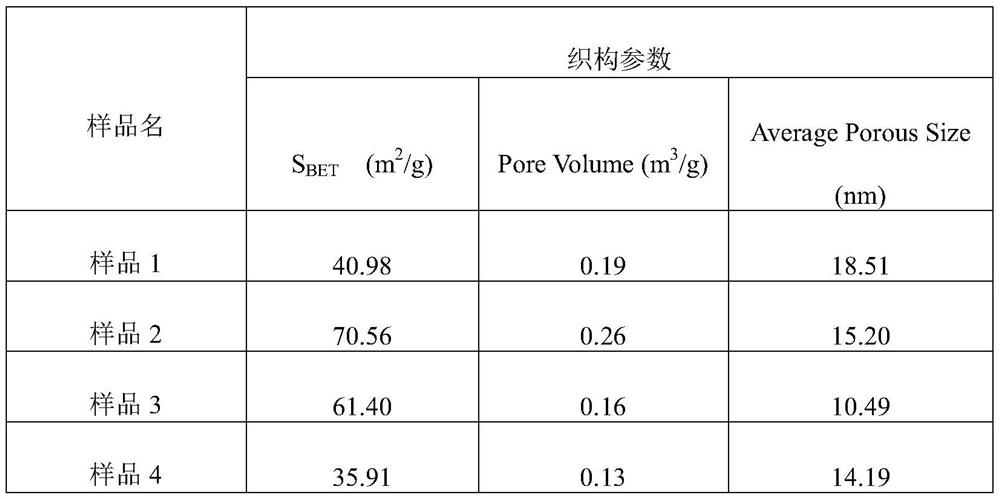

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com