A method for preparing flaky alumina based on liquid metal

A flake alumina, liquid metal technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of inconvenient removal, residual sintered mixture, etc., to reduce the introduction of impurities, reduce the generation of impurities, ensure The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

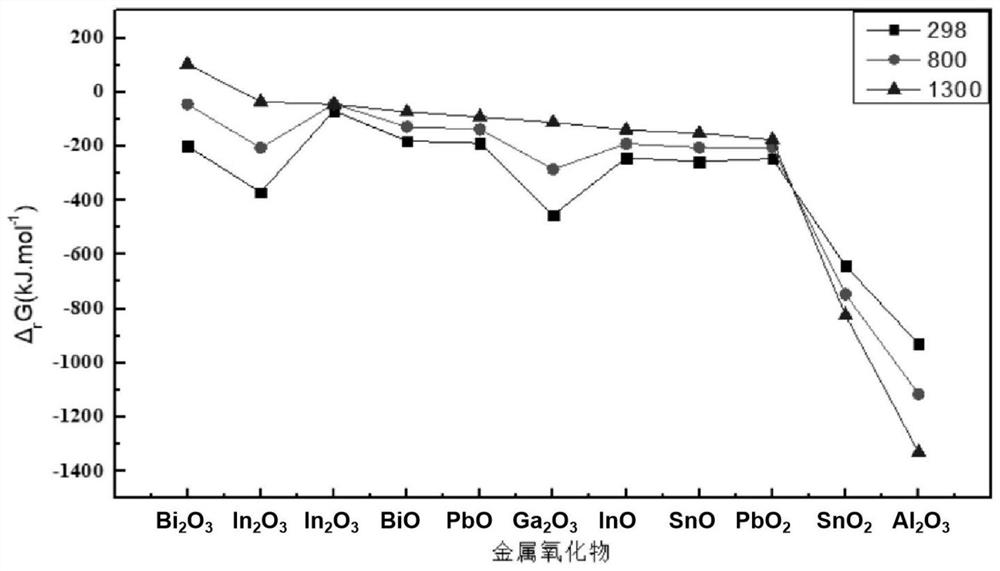

Problems solved by technology

Method used

Image

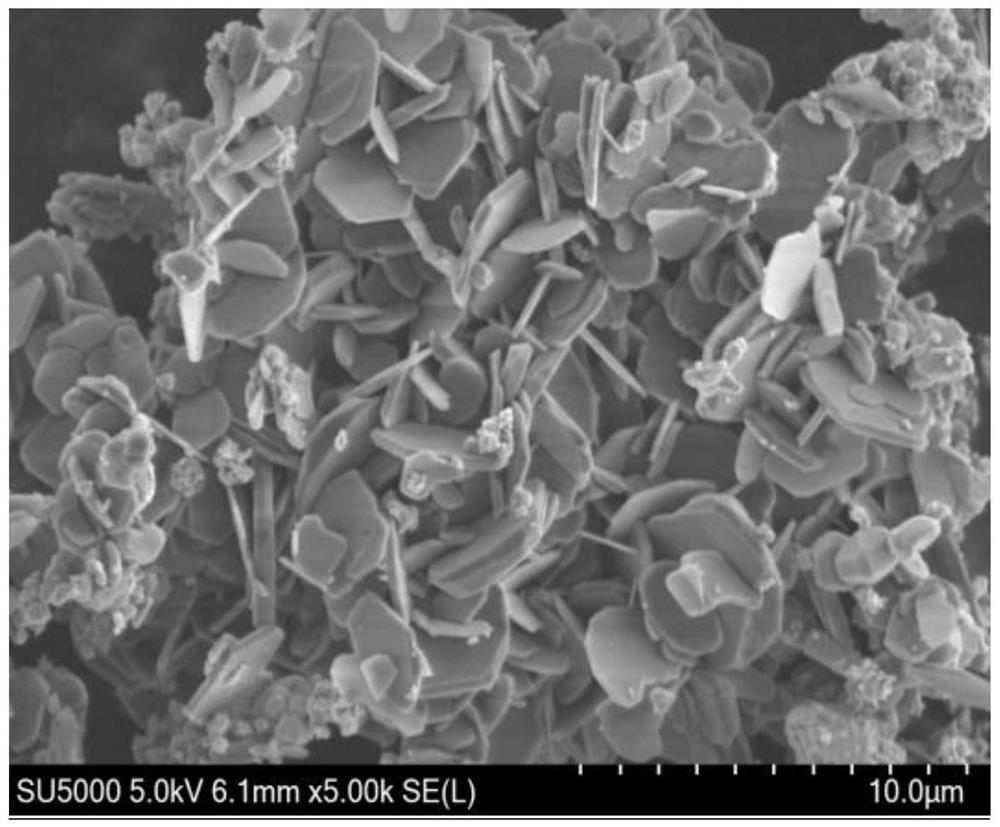

Examples

example 1

[0031] A method for preparing flaky alumina based on liquid metal, comprising the following steps:

[0032] (1) get the mixed molten salt that the mass ratio of sodium chloride and potassium chloride is 1:1 and add spherical alumina, the ratio of the amount of the molten salt to the amount of the spherical alumina is 4, and the spherical alumina is 5g ;

[0033] (2) then get 50g of bismuth-tin aluminum alloy (bismuth-tin eutectic point is 139 ℃), wherein aluminum content is less than 3at%, join in alumina crucible, then add sodium chloride, potassium chloride and spherical alumina The mixture is heated to 100-150 ℃ in a blast drying oven to dry, and kept for 1 hour to remove the moisture; the content of aluminum in bismuth-tin aluminum alloy is less than 3at% will not have a great impact on the melting point of liquid metal, such as bismuth-tin alloy. The melting point is 139°C, adding too much aluminum will raise the melting point a lot;

[0034] (3) Then put the dried cruc...

example 2

[0036] A method for preparing flaky alumina based on liquid metal, comprising the following steps:

[0037] (1) Mix 0.01mol spherical alumina and 0.05mol sodium chloride evenly.

[0038] (2) Take 30g of gallium-tin-aluminum alloy (melting point of gallium-tin eutectic is 20.5°C) or gallium-aluminum eutectic (melting point of gallium-aluminum eutectic is 26.6°C), wherein the aluminum content is less than 3at%, and add it into an alumina crucible, Then add a mixture of sodium chloride, potassium chloride and spherical alumina, put it into a blast drying oven and heat it to 100-150 ° C for drying, keep it for 1 hour, and remove the moisture; the aluminum content in the gallium-tin-aluminum alloy is less than 3at% Great influence on the melting point of liquid metal;

[0039] (3) then put the dried crucible in step (2) into a heating furnace, heat it to 1000°C, keep the temperature for 3h, cool down to 5°C above the melting point of the liquid metal, take out the calcined mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com