Preparation method of in-situ Al2O3 particle reinforced aluminum-based composite material

A particle-reinforced aluminum and composite material technology, which is applied in the field of aluminum-based composite materials, can solve the problems of difficult control of the reaction process, high reaction temperature, and difficult dispersion of particles, achieving environmental protection, good controllability, simple preparation process, and high performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

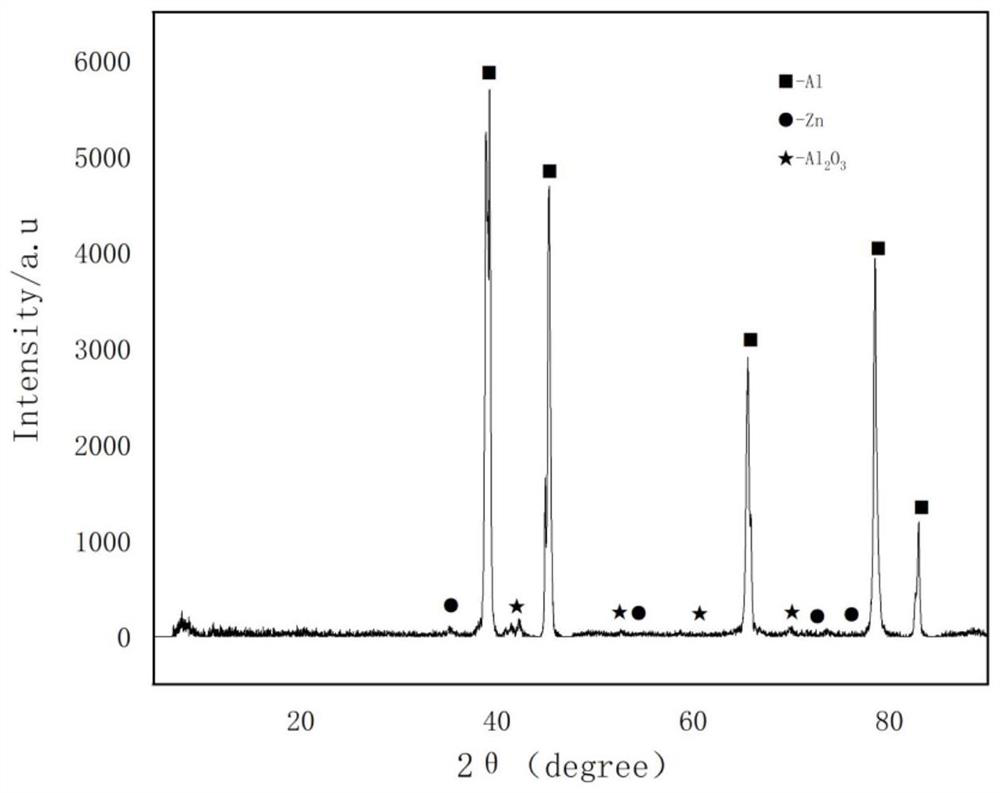

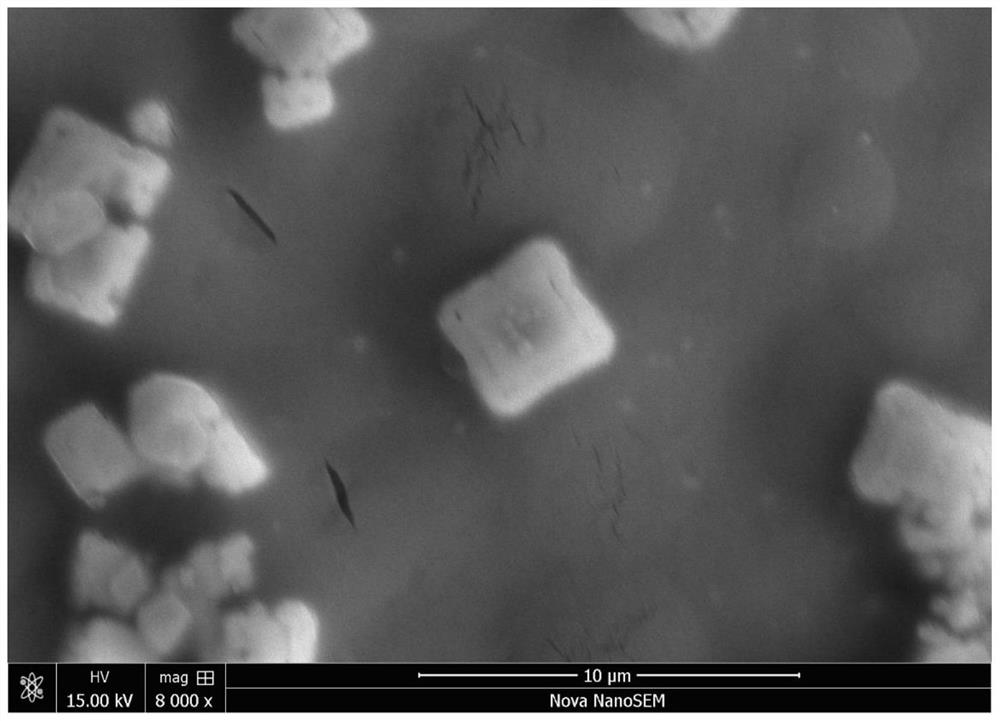

[0022] Embodiment 1 prepares 0.5vol% Al 2 o 3 / 7085 aluminum matrix composite material (Al 2 o 3 Particles account for 0.5% of the volume of the entire aluminum-based composite material, hereinafter the same) The preparation process is as follows

[0023] Mix the dried aluminum powder and nano-zinc oxide powder (20nm in diameter) in a mass ratio of 1:1, and then add them to a ball mill for ball milling at a speed of 250r / min and a ball-to-material ratio of 10:1. The ball milling time is 12 hours. Dry and preheat the mixed powder at 150°C for 2 hours, melt the 7085 aluminum alloy, cool it down to 720°C, refine and remove slag, keep it for 10 minutes, cool it down to 625°C in a semi-solid state, and carry out mechanical stirring While adding the mixed powder after ball milling, the rotation speed of the stirring paddle is 800-1200rpm, and the stirring time is 5-8min. After the mechanical stirring is completed, the melt temperature is raised to 850°C and kept for 1h, then cool...

Embodiment 2

[0024] Embodiment 2 prepares 1vol% Al 2 o 3 The preparation process of / 7085 aluminum matrix composite material is as follows

[0025] Mix the dried aluminum powder and nano-zinc oxide powder (20nm in diameter) in a mass ratio of 1:1, then add them to a ball mill for ball milling at a speed of 250r / min, and a ball-to-material ratio of 10:1. The time is 12 hours, the mixed powder after ball milling is dried and preheated at 150°C for 2 hours, the 7085 aluminum alloy is melted, the temperature is lowered to 720°C, the refining slag is removed, and after 10 minutes of heat preservation, the temperature is lowered to 625°C in a semi-solid state, and mechanical stirring is performed While adding the mixed powder after ball milling, the rotation speed of the stirring paddle is 800-1200rpm, and the stirring time is 5-8min. After the mechanical stirring is completed, the melt temperature is raised to 850°C and kept for 1h, then cooled to 750°C, and ultrasonic treatment is applied. T...

Embodiment 3

[0026] Embodiment 3 prepares 3vol%Al 2 o 3 The preparation process of / 7085 aluminum matrix composite material is as follows

[0027] Mix the dried aluminum powder and nano-zinc oxide powder (20nm in diameter) in a mass ratio of 1:1, then add them to a ball mill for ball milling at a speed of 250r / min, and a ball-to-material ratio of 10:1. The time is 12 hours, the mixed powder after ball milling is dried and preheated at 150°C for 2 hours, the 7085 aluminum alloy is melted, the temperature is lowered to 720°C, the refining slag is removed, and after 10 minutes of heat preservation, the temperature is lowered to 625°C in a semi-solid state, and mechanical stirring is performed While adding the mixed powder after ball milling, the rotation speed of the stirring paddle is 800-1200rpm, and the stirring time is 5-8min. After the mechanical stirring is completed, the melt temperature is raised to 850°C and kept for 1h, then cooled to 750°C, and ultrasonic treatment is applied. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com