Heat-stress-resistant feeding additive, preparation method and application thereof

An anti-heat stress and additive technology, applied in the field of livestock and poultry breeding, can solve problems such as obstacles, and achieve the effects of improving the degradation rate, improving the metabolic energy of livestock and poultry feed, and increasing the utilization rate of sugar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of an anti-heat stress feed additive, which comprises the following steps: mixing the feed additive described in the invention, and passing through a 30-60 mesh sieve to obtain the feed additive.

[0030] The present invention also provides an application of an anti-heat stress feed additive, that is, adding the above-mentioned feed additive to livestock and poultry feed, preferably, adding 300-500 g of the feed additive per ton of livestock and poultry feed Add to.

Embodiment 1

[0034] Weigh 70g of γ-aminobutyric acid, 60g of L-arginine, 90g of α-ketoglutarate, 70g of taurine, ferulic acid esterase (1×10 5 U / kg) 250g, xylanase (5.5×10 6 U / kg) 300g, cellulase (6×10 5 U / kg) 100g and starch 60g, cross 40 mesh sieves after mixing, obtain 1kg feed additive, and add in the corn soybean meal ration of meat duck with the addition amount of 300g / t.

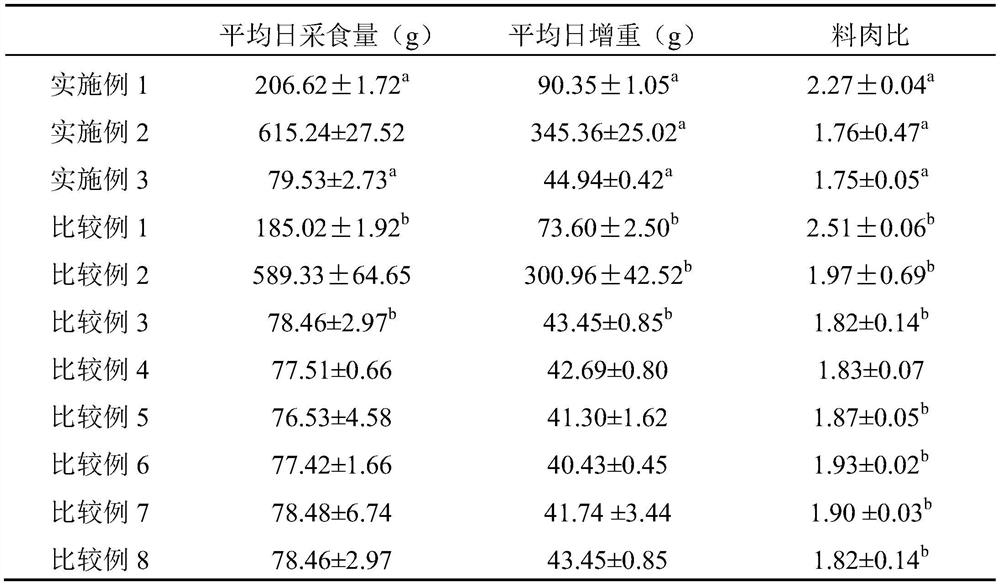

[0035] Select 105 healthy 1-day-old meat ducks with similar body weight and randomly divide them into 7 replicates according to the principle of similar body weight and half male and female. Each replicate has 16 ducks. They are fed with the same amount of the above-mentioned rations every day. The test lasts for 42 days. , Keep the temperature in the duck house at 31-33°C during the test. The production performance data of meat ducks are shown in Table 1.

Embodiment 2

[0037] Weigh respectively 40g of γ-aminobutyric acid, 80g of L-arginine, 90g of α-ketoglutarate, 80g of taurine, ferulic acid esterase (1×10 5 U / kg) 150g, xylanase (5.5×10 6 U / kg) 350g, cellulase (6×10 5 U / kg) 150g and starch 60g, pass through 40 mesh sieves after mixing, obtain 1kg feed additive, and add in the corn soybean meal ration of weaned piglet with the addition amount of 300g / t.

[0038] Select 7 healthy 21-day-old weaned piglets with similar body weight, randomly divide them into 7 replicates according to the principle of similar body weight, and feed one piglet with the same amount of the above-mentioned diet every day. The experiment lasts for 21 days. The temperature in the house is 31-33°C. The production performance data of weaned piglets are shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap