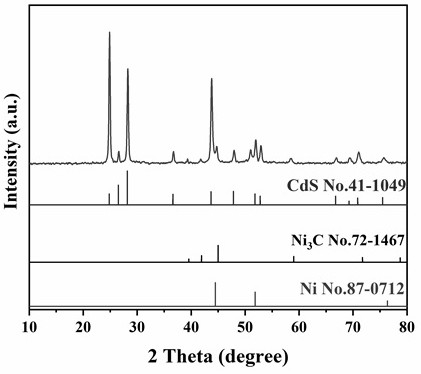

Preparation method and application of Ni/Ni3C/CdS nanowire catalyst with photocatalytic performance

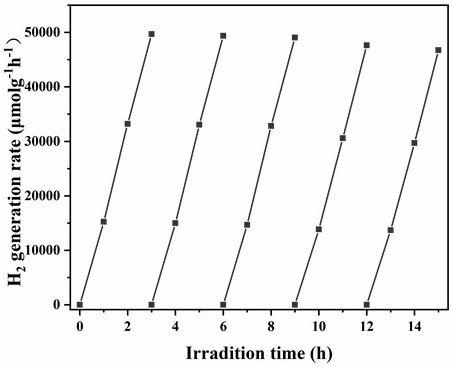

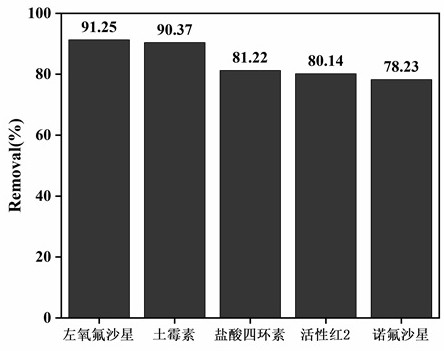

A photocatalyst and nanowire technology, applied in the field of photocatalysis, can solve the problems of limiting the photocatalytic performance of cadmium sulfide, being easy to be corroded by light, and unable to exist stably for a long time, and achieving excellent hydrogen production performance, easy recovery and stability. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a Ni / Ni3C / CdS nanowire catalyst with photocatalytic performance, and its preparation method comprises the following steps:

[0025] (1) Cadmium chloride 0.685g, sodium diethyldithiocarbamate trihydrate 1.35g. Dissolve them in 50ml of deionized water respectively, add the cadmium chloride solution dropwise into the sodium diethyldithiocarbamate trihydrate solution, and stir while dropping. After stirring for 1 h, wash with deionized water and absolute ethanol, centrifuge and dry.

[0026] (2) Dissolve the obtained solid in 40ml of ethylenediamine, and stir until dissolved. The solution was transferred to a 60ml reaction kettle, and reacted for 24h in an oven at 180°C. After the reactor was cooled to room temperature, it was washed with deionized water, centrifuged, and freeze-dried. CdS in the form of nanofibers was obtained.

[0027] (3) 100mg of CdS, 0.2mmol of nickel nitrate hexahydrate and 0.4mmol of hexamethylenetetramine were dissolved ...

Embodiment 2

[0030] This embodiment provides a Ni / Ni3C / CdS nanowire catalyst with photocatalytic performance, and its preparation method comprises the following steps:

[0031] (1) Cadmium chloride 0.685g, sodium diethyldithiocarbamate trihydrate 1.35g. Dissolve them in 50ml of deionized water respectively, add the cadmium chloride solution dropwise into the sodium diethyldithiocarbamate trihydrate solution, and stir while dropping. After stirring for 1 h, wash with deionized water and absolute ethanol, centrifuge and dry.

[0032] (2) Dissolve the obtained solid in 40ml of ethylenediamine, and stir until dissolved. The solution was transferred to a 60ml reaction kettle, and reacted for 24h in an oven at 180°C. After the reactor was cooled to room temperature, it was washed with deionized water, centrifuged, and freeze-dried. CdS in the form of nanofibers was obtained.

[0033] (3) 100mg of CdS, 0.3mmol of nickel nitrate hexahydrate and 0.6mmol of hexamethylenetetramine were dissolved ...

Embodiment 3

[0036] This embodiment provides a Ni / Ni3C / CdS nanowire catalyst with photocatalytic performance, and its preparation method comprises the following steps:

[0037] (1) Cadmium chloride 0.685g, sodium diethyldithiocarbamate trihydrate 1.35g. Dissolve them in 50ml of deionized water respectively, add the cadmium chloride solution dropwise into the sodium diethyldithiocarbamate trihydrate solution, and stir while dropping. After stirring for 1 h, wash with deionized water and absolute ethanol, centrifuge and dry.

[0038] (2) Dissolve the obtained solid in 40ml of ethylenediamine, and stir until dissolved. The solution was transferred to a 60ml reaction kettle, and reacted for 24h in an oven at 180°C. After the reactor was cooled to room temperature, it was washed with deionized water, centrifuged, and freeze-dried. CdS in the form of nanofibers was obtained.

[0039](3) 100mg of CdS, 0.4mmol of nickel nitrate hexahydrate and 0.8mmol of hexamethylenetetramine were dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com