Zirconolite glass ceramic curing base material and preparation method thereof

A technology for glass ceramics and perovskite zircon, which is applied in the field of perovskite zircon glass ceramic solidified substrates and their preparation, can solve difficult problems, affect the solidification effect of artificial rocks on radioactive waste, and the technology of artificial rocks solidifying high-level radioactive waste. Complicated and other problems, to achieve the effect of low cost, excellent mechanical properties, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

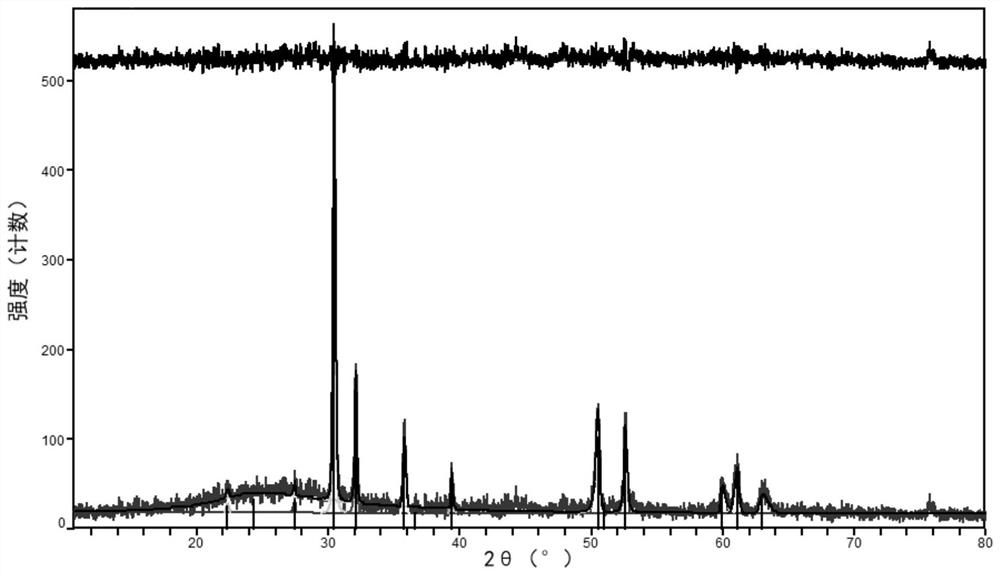

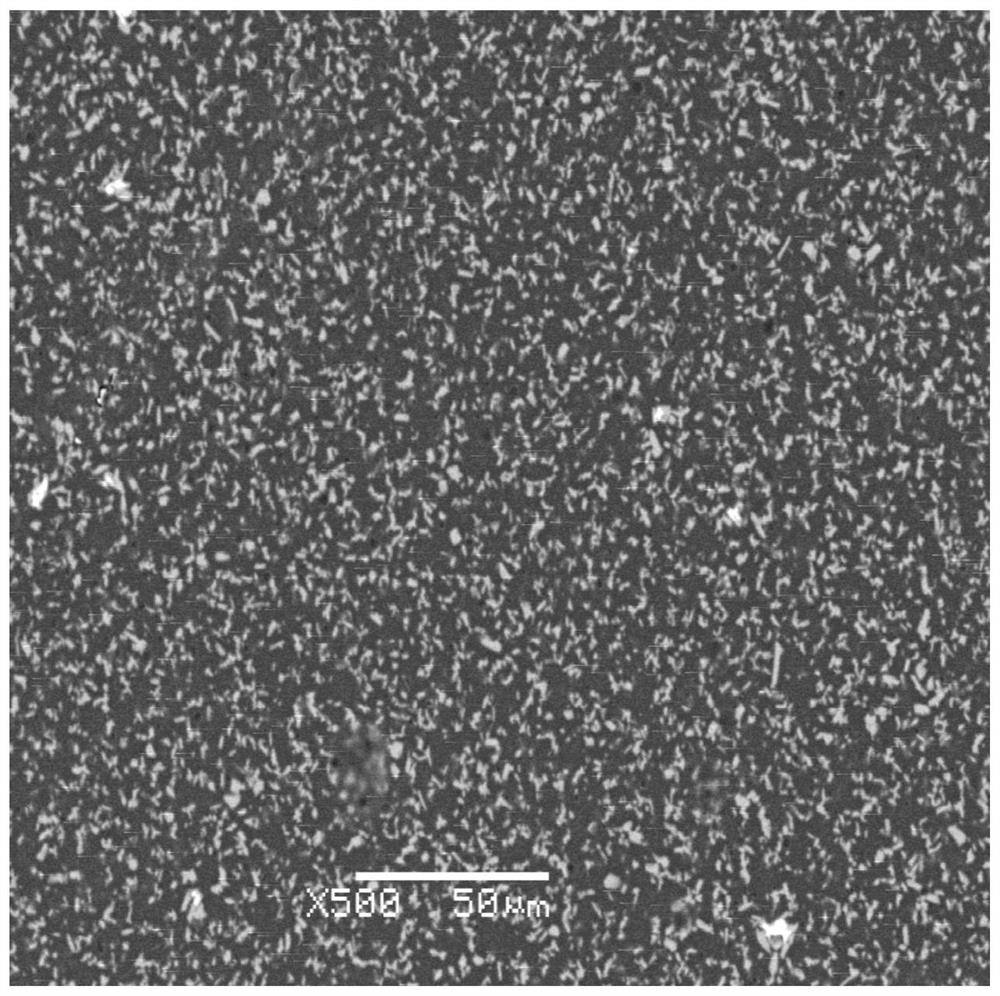

Embodiment 1

[0032] A perovskite zircon glass ceramic solidified substrate, the preparation method is as follows:

[0033] (1) Raw material preparation: Prepare the following raw materials by mass percentage: SiO 2 33%, B 2 o 3 10%, Na 2 CO 3 13%, Al 2 o 3 3.5%, CaO 10.3%, ZrO 2 11.4%, TiO 2 14.8% and CeO 2 4%, the above raw materials are powder raw materials, the particle size is less than 200 mesh;

[0034] (2) mixing and stirring: put each raw material into an alumina crucible and fully mix and stir evenly;

[0035] (3) thermal decomposition: put the crucible with raw materials into the muffle furnace and heat to 865°C, and heat at this temperature for 2 hours;

[0036] (4) High-temperature melting: continue to heat the temperature of the raw materials to 1400°C, and melt at this temperature for 3 hours to make a molten glass;

[0037] (5) Rapid cooling: Pour molten glass into a mold preheated to 500°C, and rapidly cool and solidify at room temperature to form a glass ...

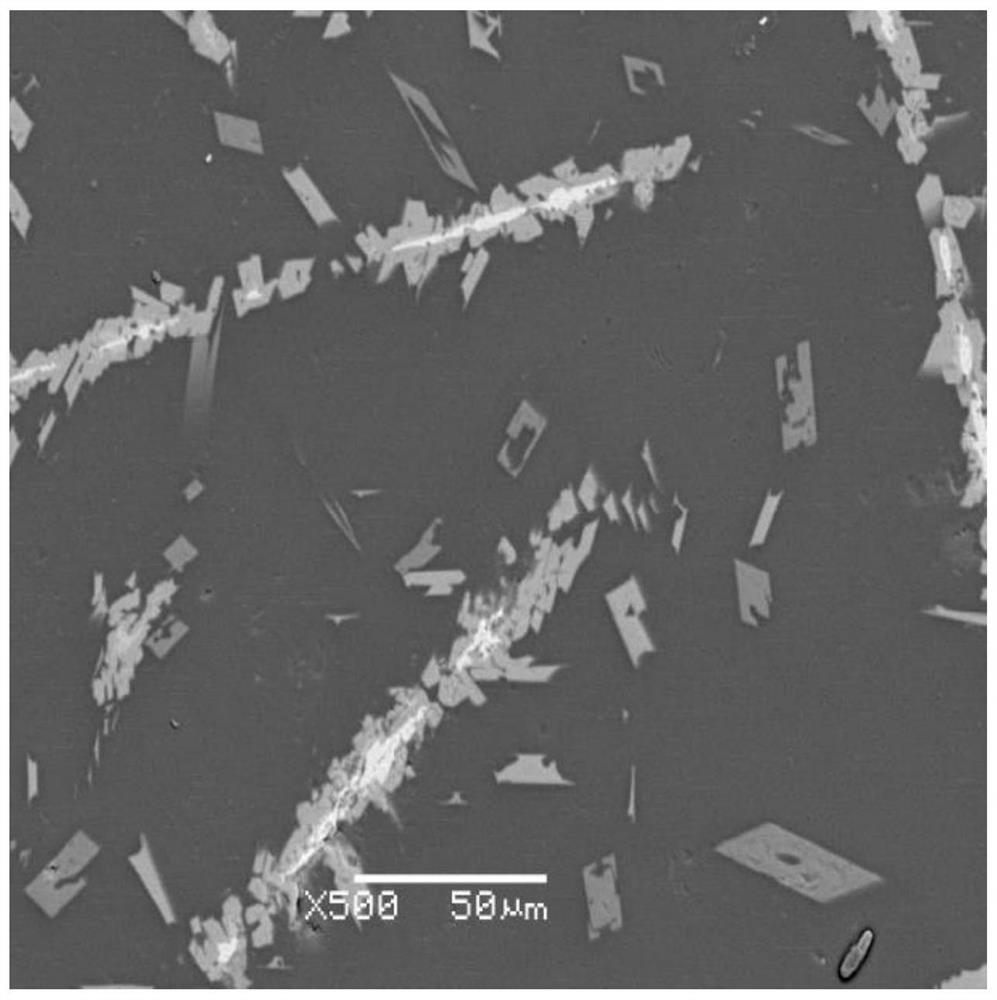

Embodiment 2

[0044] A perovskite zircon glass ceramic solidified substrate, the preparation method is as follows:

[0045] (1) Raw material preparation: Prepare the following raw materials by mass percentage: SiO 2 30%, B 2 o 3 11%, Na 2 CO 3 12.3%, Al 2 o 3 3%, CaO 9.8%, ZrO 2 10.9%, TiO 2 13% and CeO 2 10%, the above raw materials are powder raw materials, the particle size is less than 200 mesh;

[0046] (2) mixing and stirring: put each raw material into an alumina crucible and fully mix and stir evenly;

[0047] (3) thermal decomposition: put the crucible with raw materials into the muffle furnace and heat to 900°C, and heat at this temperature for 2 hours;

[0048] (4) High-temperature melting: continue to heat the temperature of the raw material to 1300°C, and melt at this temperature for 4 hours to make a molten glass;

[0049] (5) Rapid cooling: Pour molten glass into a mold preheated to 400°C, and rapidly cool and solidify at room temperature to form a glass mat...

Embodiment 3

[0055] A perovskite zircon glass ceramic solidified substrate, the preparation method is as follows:

[0056] (1) Raw material preparation: Prepare the following raw materials by mass percentage: SiO 2 35%, B 2 o 3 9%, Na 2 CO 3 13.5%, Al 2 o 3 4%, CaO 11%, ZrO 2 12%, TiO 2 13.5% and CeO 2 2%, the above raw materials are powder raw materials, the particle size is less than 200 mesh;

[0057] (2) mixing and stirring: put each raw material into an alumina crucible and fully mix and stir evenly;

[0058] (3) thermal decomposition: put the crucible with raw materials into the muffle furnace and heat to 850°C, and heat at this temperature for 3 hours;

[0059] (4) High-temperature melting: continue to heat the temperature of the raw material to 1300°C, and melt at this temperature for 4 hours to make a molten glass;

[0060] (5) Rapid cooling: Pour molten glass into a mold preheated to 450°C, and rapidly cool and solidify at room temperature to form a glass matrix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com