Lightweight concrete

A lightweight concrete, high-quality technology, applied in the field of concrete, can solve the problems of unstable foam, high price, insufficient compressive strength, etc., and achieve the effect of simple and convenient operation method, reduction of production cost, and reduction of raw material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

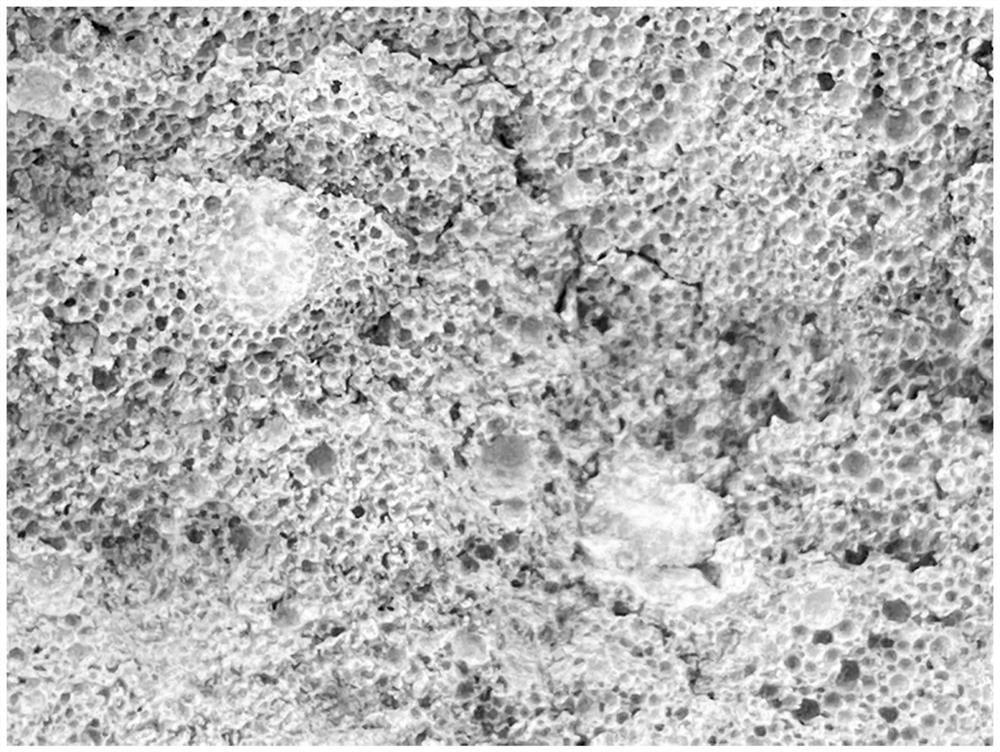

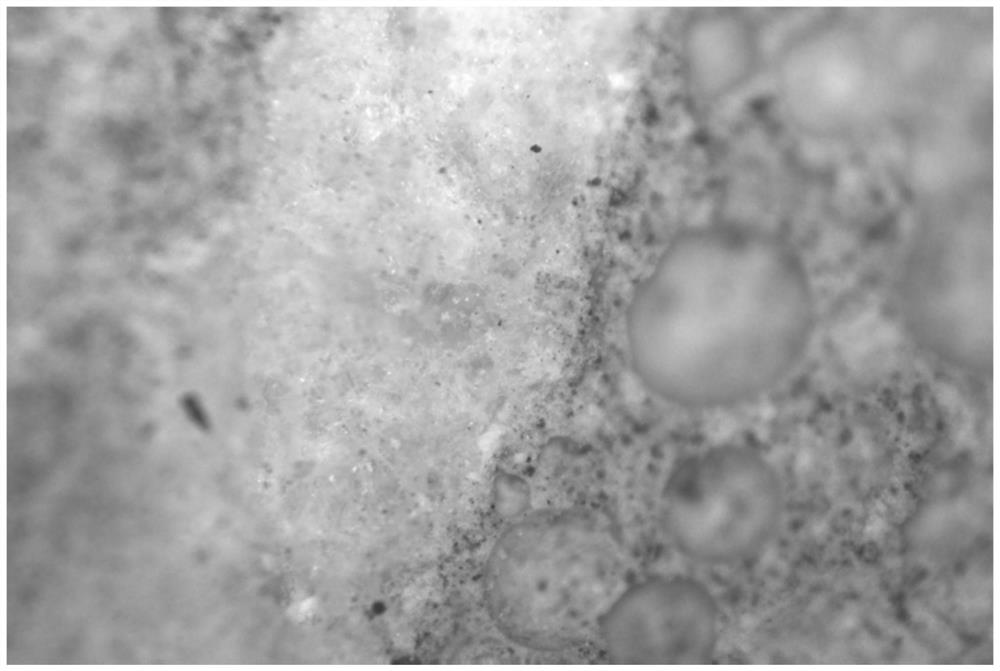

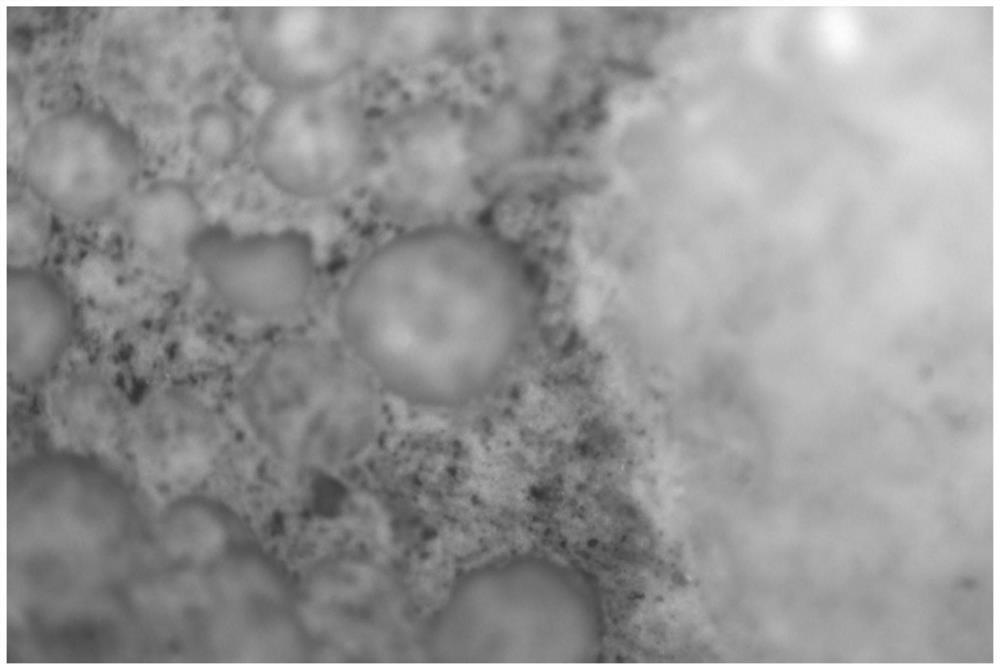

Image

Examples

Embodiment 1

[0077] The raw material composition of the lightweight concrete in this example can be seen in Table 1.

[0078] The preparation method of this example lightweight concrete comprises the following steps:

[0079] Weigh 400g of cement, 4g of perlite and 180mL of water and mix to obtain a slurry.

[0080] Mix the surface hydrophilic modified nano-attapulgite powder, sodium dodecylbenzenesulfonate, polyacrylamide, polyethyleneimine, polyvinylpyrrolidone, methylcellulose and triethanolamine in proportion, and then mix them according to the mass ratio 1:300 is mixed with water to obtain a blowing agent solution; the mass content of each raw material of the prepared blowing agent solution is as follows: 0.06% of nano-attapulgite powder with hydrophilic modification on the surface of silane coupling agent, dodecylbenzenesulfonate Sodium phosphate 0.08%, polyacrylamide 0.016%, polyethyleneimine 0.016%, polyvinylpyrrolidone 0.04%, methylcellulose 0.18%, triethanolamine 0.008%, and the...

Embodiment 2

[0083] The raw material composition of the lightweight concrete in this example can be seen in Table 1. The only difference between this example and Example 1 is that the amount of perlite is 12g, that is, the addition amount relative to cement is changed from 1wt% to 3wt%, and the rest of the raw material composition and preparation method are the same as in Example 1.

Embodiment 3

[0085] The raw material composition of the lightweight concrete in this example can be seen in Table 1.

[0086] The preparation method of this example lightweight concrete comprises the following steps:

[0087] Weigh 250g of cement, 150g of fly ash, 4g of perlite and mix with 180mL of water to obtain a slurry.

[0088] Mix the surface hydrophilic modified nano-attapulgite powder, sodium dodecylbenzenesulfonate, polyacrylamide, polyethyleneimine, polyvinylpyrrolidone, methylcellulose and triethanolamine in proportion, and then mix them according to the mass ratio 1:300 is mixed with water to obtain a blowing agent solution; the mass content of each raw material of the prepared blowing agent solution is as follows: 0.06% of nano-attapulgite powder with hydrophilic modification on the surface of silane coupling agent, dodecylbenzenesulfonate Sodium phosphate 0.08%, polyacrylamide 0.016%, polyethyleneimine 0.016%, polyvinylpyrrolidone 0.04%, methylcellulose 0.18%, triethanolami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wet density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap