Coating for improving wear resistance of PVC (polyvinyl chloride) whole-core flame-retardant conveyor belt and preparation method of coating

A conveyor belt and wear-resistant technology, applied in the field of wear-resistant coating and its preparation, can solve the problems of poor wear resistance, loss of use value of the conveyor belt, large wear of the conveyor belt, etc., and achieve flame retardancy and antistatic properties Excellent, flexible and convenient treatment method, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

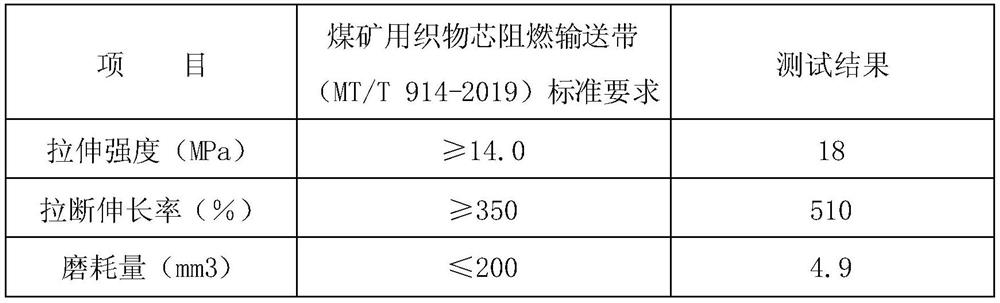

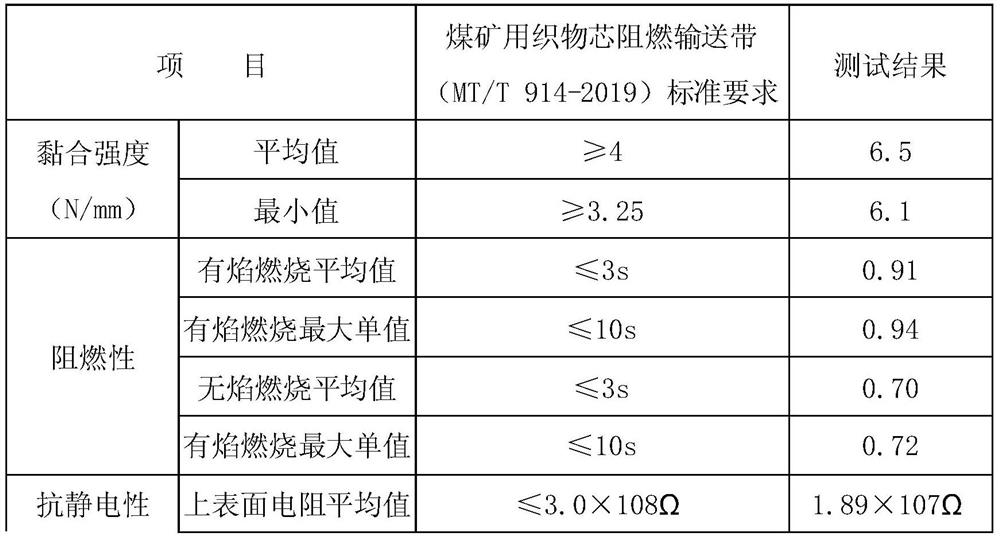

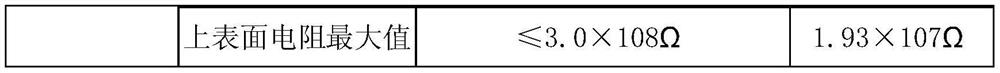

Examples

Embodiment 1

[0026] 1.1) Preparation of active interface treatment agent

[0027] Add 28kg of methyl ethyl ketone, 10kg of isopropanol, 15kg of propylene glycol diacetate, 12kg of dimethyl nylon acid and 35kg of polyester diol L3025 into the dispersing tank, stir until uniform with a disperser, and finally use a 200-mesh wire After mesh filtration, the active interface treatment agent is obtained and set aside.

[0028] 1.2) Composition of component A and component B of modified polyurethane coating

[0029] Component A is a semi-prepolymer synthesized from the following raw materials: 55kg polyester diol L3025, 35kg aromatic isocyanate MDI50, 10kg propylene carbonate;

[0030] Component B is composed of the following raw materials: 15kg dimethylthiotoluenediamine DMTDA, 55kg polytetramethylene ether glycol PTMG2000, 18kg halogen-free environmental protection liquid flame retardant FR-633, 3kg antistatic agent Basionics LQ01, 5kg Molecular sieve SYLOSIV A3, 0.1kg organic bismuth catalyst...

Embodiment 2

[0050] 1.1) Composition of component A and component B of modified polyurethane coating

[0051] Component A is a semi-prepolymer synthesized from the following raw materials: 50kg polyester diol L3025, 42kg aromatic isocyanate MDI100, 8kg propylene carbonate;

[0052] Component B is composed of the following raw materials: 15kg dimethylthiotoluenediamine DMTDA, 5kg diethyltoluenediamine DETDA, 15kg polytetramethylene ether glycol PTMG1000, 35kg polytetramethylene ether glycol PTMG2000, 9kg halogen-free environmentally friendly liquid flame retardant FR-633, 9kg halogen-free environmentally friendly liquid flame retardant FR-632, 3kg antistatic agent Basionics LQ01, 5kg molecular sieve SYLOSIV A3, 0.1kg organic bismuth catalyst BiCAT8118, 3.8kg polyurethane universal red paste ( Its water content ≤0.5%), 0.1kg defoamer BYK023.

[0053] 1.2) Preparation of component A and component B of modified polyurethane coating

[0054] The preparation process of component A is as follow...

Embodiment 3

[0071] 1.1) Composition of component A and component B of modified polyurethane coating

[0072] Component A is a semi-prepolymer synthesized from the following raw materials: 52kg polyester diol L3025, 48kg aromatic isocyanate MDI50;

[0073] Component B is composed of the following raw materials: 15kg dimethylthiotoluenediamine DMTDA, 10kg diethyltoluenediamine DETDA, 10kg polytetramethylene ether glycol PTMG1000, 35kg polytetramethylene ether glycol PTMG2000, 18kg halogen-free environment-friendly liquid flame retardant FR-632, 3kg antistatic agent Basionics LQ01, 5kg molecular sieve SYLOSIV A3, 0.1kg organic bismuth catalyst BiCAT8118, 3.8kg polyurethane universal black paste (water content ≤ 0.5%), 0.1kg Defoamer BYK023.

[0074] 1.2) Preparation of component A and component B of modified polyurethane coating

[0075] The preparation process of component A is as follows:

[0076] Put 52kg of polyester diol L3025 in the reactor, start stirring, heat to 100-120°C, dehydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com