Nanoparticle composite magnetic core film and preparation method thereof

A nanoparticle and composite film technology, applied in magnetic thin films, nanostructure applications, transformer/inductor cores, etc., can solve the problems of reducing saturation magnetization and magnetic permeability, achieve low coercivity and improve resistivity , the effect of excellent soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a nanoparticle composite magnetic core film, specifically comprising the following steps:

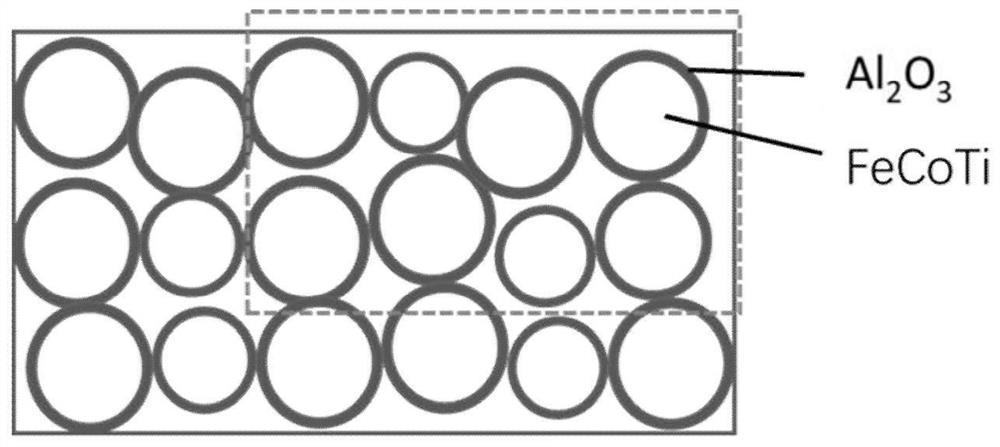

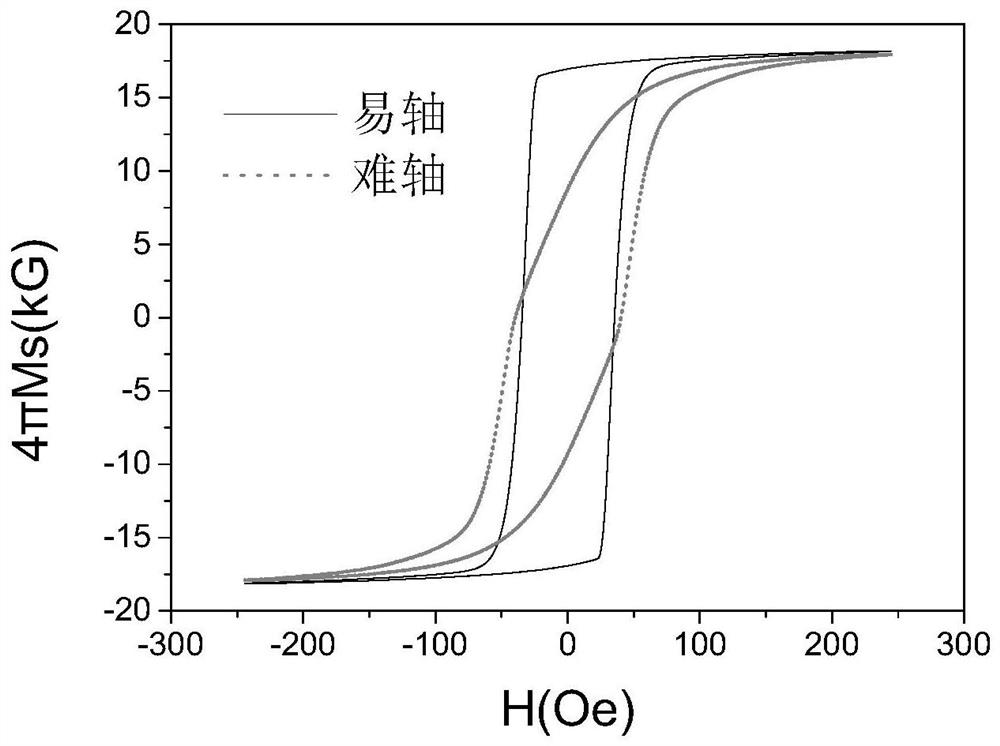

[0025] Step 1, adopt radio frequency magnetron sputtering method, with Fe 65 co 35 Alloys, Ti and Al 2 o 3 The patch is a composite target (through the Fe 65 co 35 3 pieces of Ti and 2 pieces of Al are pasted on the target 2 o 3 chip implementation), the target diameter is 3 inches, and FeCoTi / Al is prepared on Si(100) substrate 2 o 3 Composite thin film, sputtering power is 6W / cm 2 , the sputtering pressure is 0.17Pa, a 200Oe magnetic field is applied to induce in-plane uniaxial anisotropy, the direction of the magnetic field is parallel to the film plane, and the deposition time is controlled so that the thickness of the composite film is 200nm.

[0026] Step 2. Before annealing, Ti is not oxidized, the insulating phase content is relatively low, and the growth inhibition effect on FeCo particles is relatively weak, and the FeCo particles are rel...

Embodiment 2

[0033] A method for preparing a nanoparticle composite magnetic core film, specifically comprising the following steps:

[0034] Step 1, adopt radio frequency magnetron sputtering method, with Fe 65 co 35 Alloys, Ti and Al 2 o 3 The patch is a composite target (through the Fe 65 co 35 3 pieces of Ti and 2 pieces of Al are pasted on the target 2 o 3 chip implementation), the target diameter is 3 inches, and FeCoTi / Al is prepared on Si(100) substrate 2 o 3 Composite thin film, sputtering power is 6W / cm 2 , the sputtering pressure is 0.17Pa, a 200Oe magnetic field is applied to induce in-plane uniaxial anisotropy, the direction of the magnetic field is parallel to the film plane, and the deposition time is controlled so that the thickness of the composite film is 200nm.

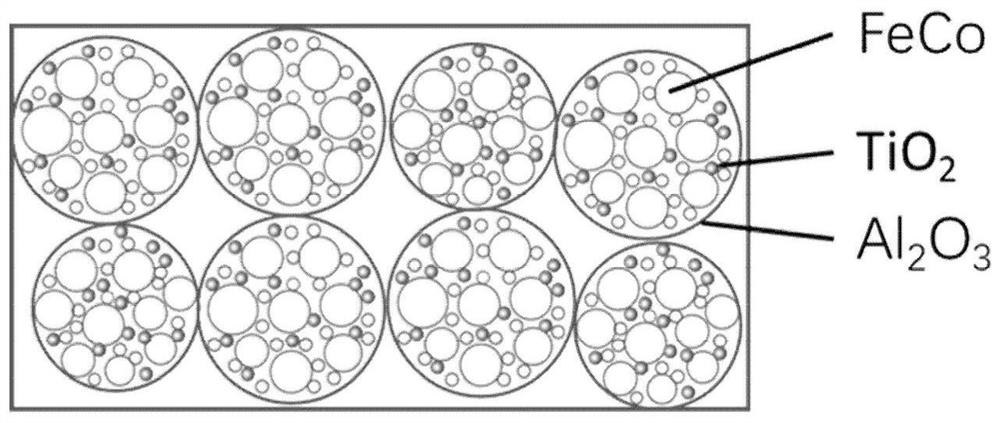

[0035] Step 2, the FeCoTi / Al that step 1 obtains 2 o 3 Put the composite film into the annealing furnace, then pass in air at 1 atmosphere, raise the temperature from room temperature to 320 °C at a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com