Multifunctional water-based binder for sodium-ion battery and application of multifunctional water-based binder

A sodium-ion battery, water-based binder technology, applied in the direction of acid copolymer adhesives, adhesives, secondary batteries, etc., can solve the problems of poor battery cycle stability, low initial inventory efficiency, low bonding strength, etc. Improve cycle stability, improve the first coulomb efficiency and rate performance, and inhibit the effect of decomposition reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

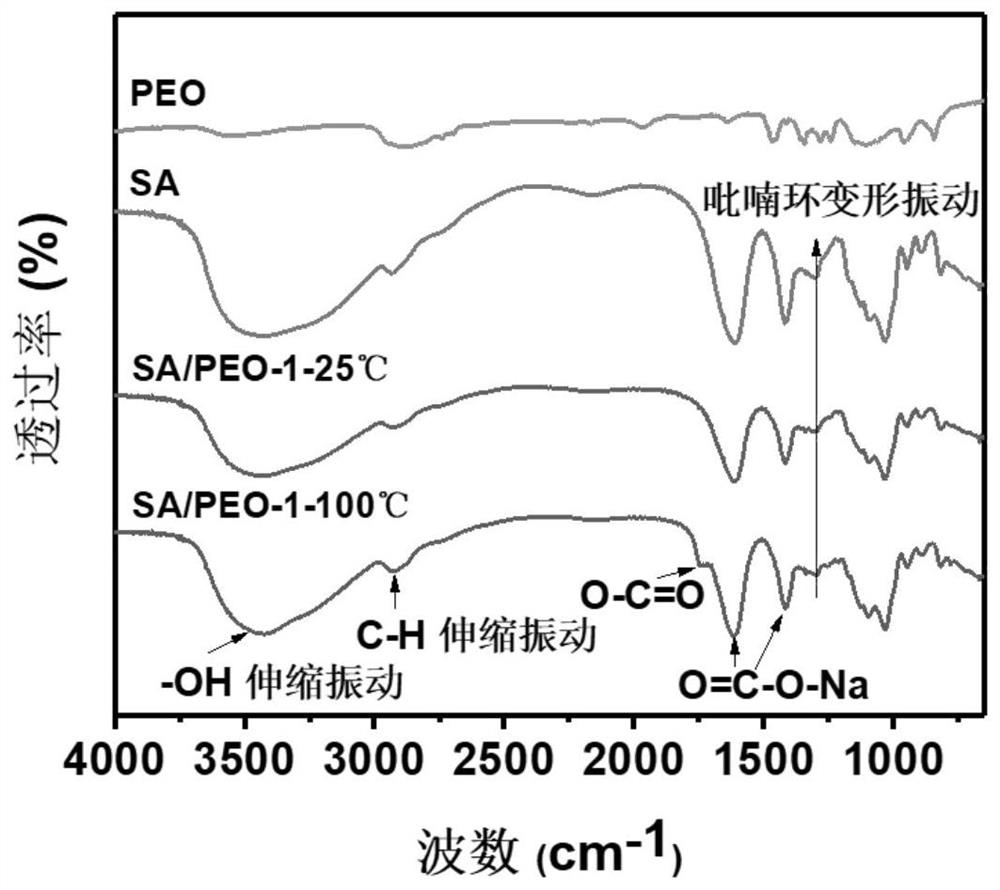

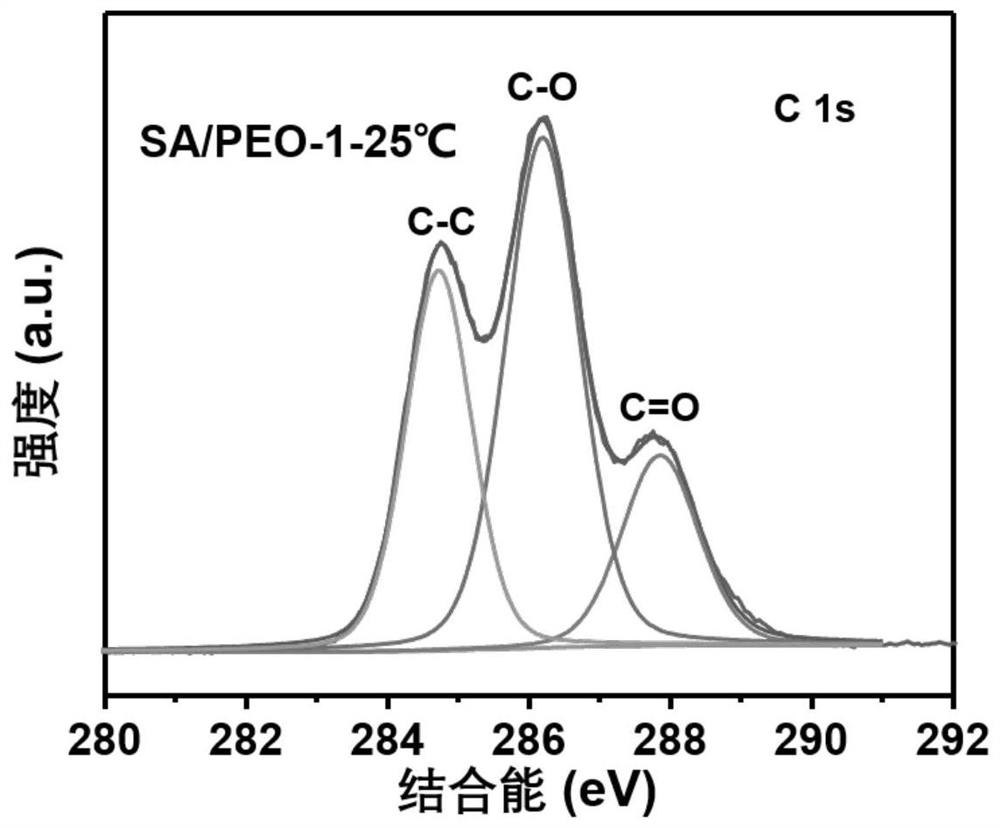

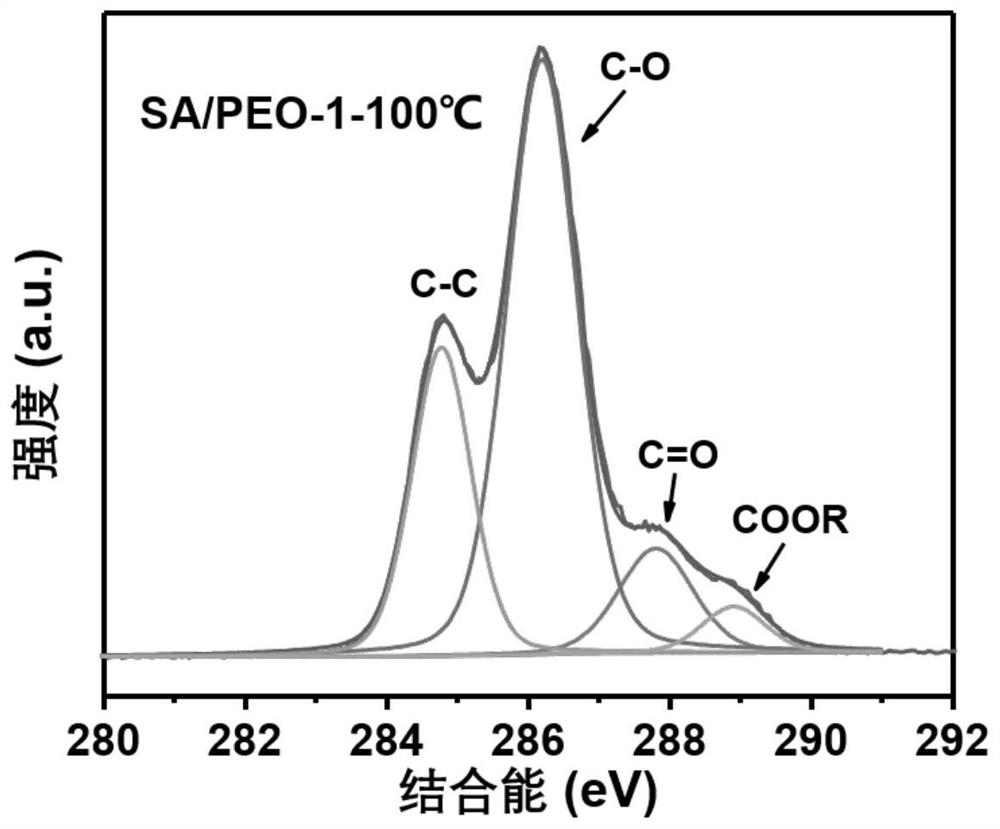

[0046]The fourth object of the present invention is to provide a preparation method of the above-mentioned sodium ion battery electrode sheet, comprising the following steps: mixing the multifunctional aqueous binder and active material for the sodium ion battery to obtain a slurry, and coating the slurry Covering the current collector to obtain a coating, and then drying the coating under normal pressure and vacuum drying successively to obtain an electrode sheet for a sodium ion battery, wherein the vacuum drying temperature is 80-120°C, preferably 100°C. The multifunctional water-based binder for sodium-ion batteries of this application completes the curing reaction process during the electrode drying process. The reaction conditions are mild, and the entire process of electrode preparation also meets the requirements of green and safe production. It is easy to control, high in feasibility, and suitable for industrial scale production. .

[0047] Preferably, the normal pres...

Embodiment 1

[0056] This embodiment provides a multifunctional water-based binder for sodium-ion batteries. The preparation method is as follows: Weigh 0.5g sodium carboxymethylcellulose and 0.5g polyethylene oxide into a beaker, then measure 32.3mL to Ionized water was added into the beaker, stirred and dissolved to obtain a multifunctional water-based binder for sodium-ion batteries, which was denoted as CMC / PEO.

Embodiment 2

[0058] This embodiment provides a multifunctional water-based binder for sodium-ion batteries. The preparation method is as follows: Weigh 0.8g of sodium polyacrylate and 0.2g of polyethylene oxide into a beaker, then measure 32.3mL of deionized water and add Put it into a beaker, stir and dissolve to obtain a multifunctional water-based binder for sodium-ion batteries, which is designated as SP / PEO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com