An integrated platform and method for ultrasonic-assisted synchronous welding and heat treatment

An auxiliary synchronization and integrated platform technology, applied in heat treatment furnaces, heat treatment equipment, welding equipment, etc., can solve problems such as reduction of hot crack tendency, increase in strength, refinement of weld grains, etc., to achieve increased strength, convenient operation, and safety. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

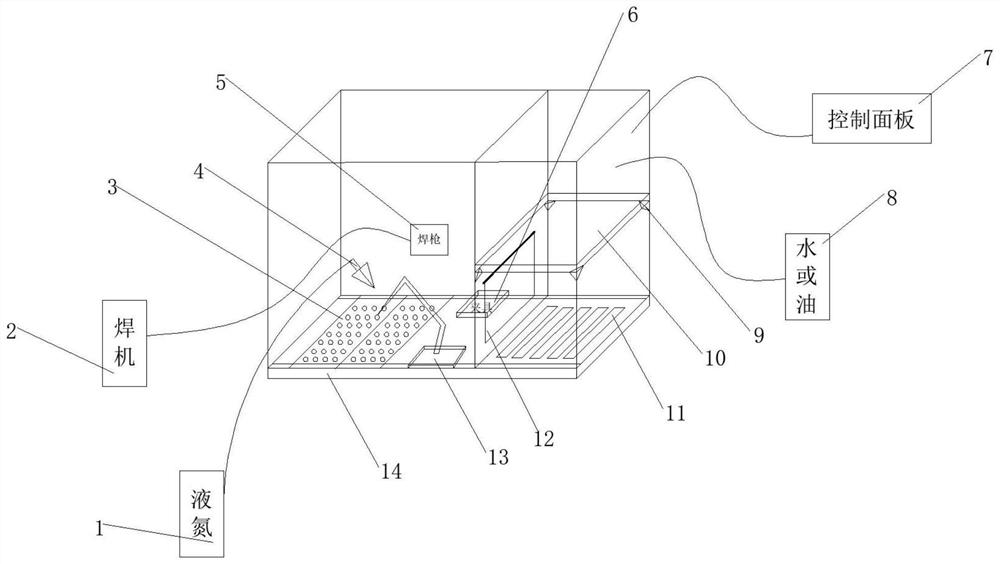

[0032] Example 1: as figure 1 As shown, an integrated platform for ultrasonic-assisted synchronous welding and heat treatment includes a box body, a welding backing plate 3, a liquid nitrogen nozzle 4, a welding torch 5, a fixture 6, a control panel 7, a moving backing plate 10, a heating base plate 11, an electric Window 12, mechanical arm 13, ultrasonic vibration plate 14 and vertical partition,

[0033] The vertical partition is vertically fixed in the box, and the two sides of the vertical partition are respectively the welding cavity and the heat treatment cavity. The ultrasonic vibration plate 14 is arranged at the bottom of the box and the ultrasonic vibration plate 14 is located in the welding cavity. The welding pad The plate 3 is arranged at the top of the ultrasonic vibration plate 14, the bottom end of the robotic arm 13 is fixedly arranged at the bottom of the box body, and the robotic arm 13 is located between the welding pad 3 and the heating base plate 11, and ...

Embodiment 2

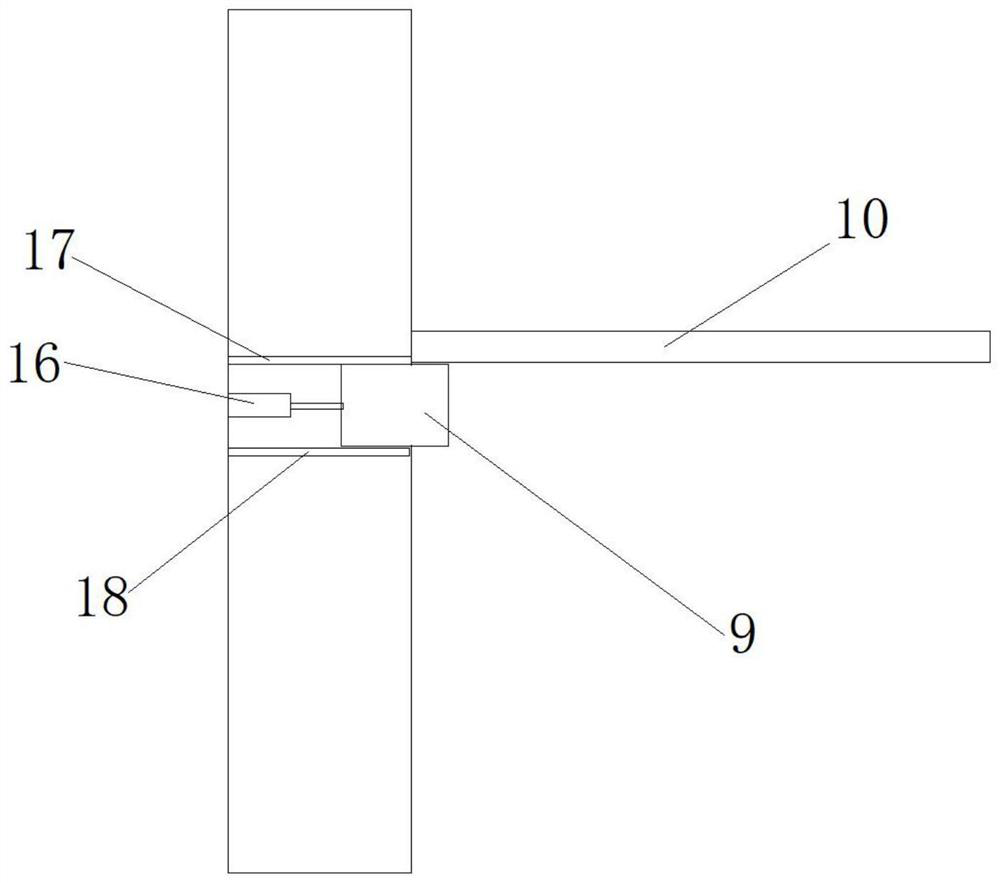

[0042] Example 2: The integrated platform for ultrasonic-assisted synchronous welding and heat treatment in this embodiment is basically the same as the integrated platform for ultrasonic-assisted synchronous welding and heat treatment in Example 1, except that the four corners of the moving backing plate 10 are provided with rollers , the four corners of the heat treatment cavity are vertically provided with longitudinal slide rails, and the rollers are slidably arranged on the longitudinal slide rails; the moving backing plate 10 is a magnetic backing plate, and a ring-shaped electromagnet is arranged on the inner wall of the middle part of the heat treatment chamber. The ring-shaped electromagnet Located on the edge of the sealing ring, the annular electromagnet is connected to the control panel 7;

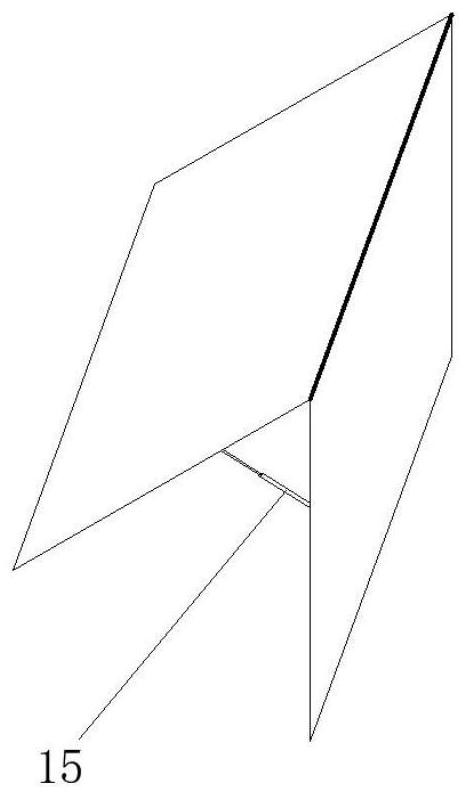

[0043] like figure 2 As shown, the four corners of the heat treatment chamber are provided with support members, the support members include support beams 9, electric telescop...

Embodiment 3

[0047] Embodiment 3: The integrated platform for ultrasonic-assisted synchronous welding and heat treatment in this embodiment is basically the same as the integrated platform for ultrasonic-assisted synchronous welding and heat treatment in Embodiment 2, except that the ultrasonic vibration plate 14 includes a vibrating top plate, a casing , Ultrasonic generator, the vibrating top plate is fixed on the top of the shell, the shell is filled with water, the transmitting end of the ultrasonic generator is set with the center in the shell, and the ultrasonic generator is connected with the control panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com