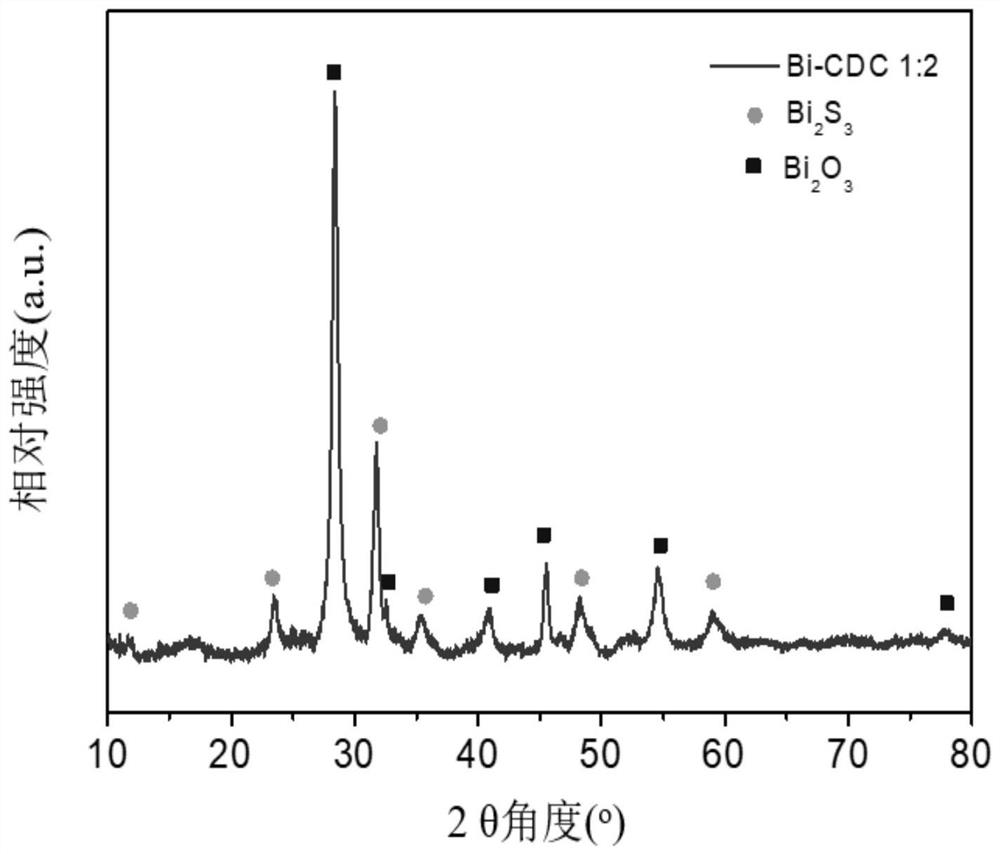

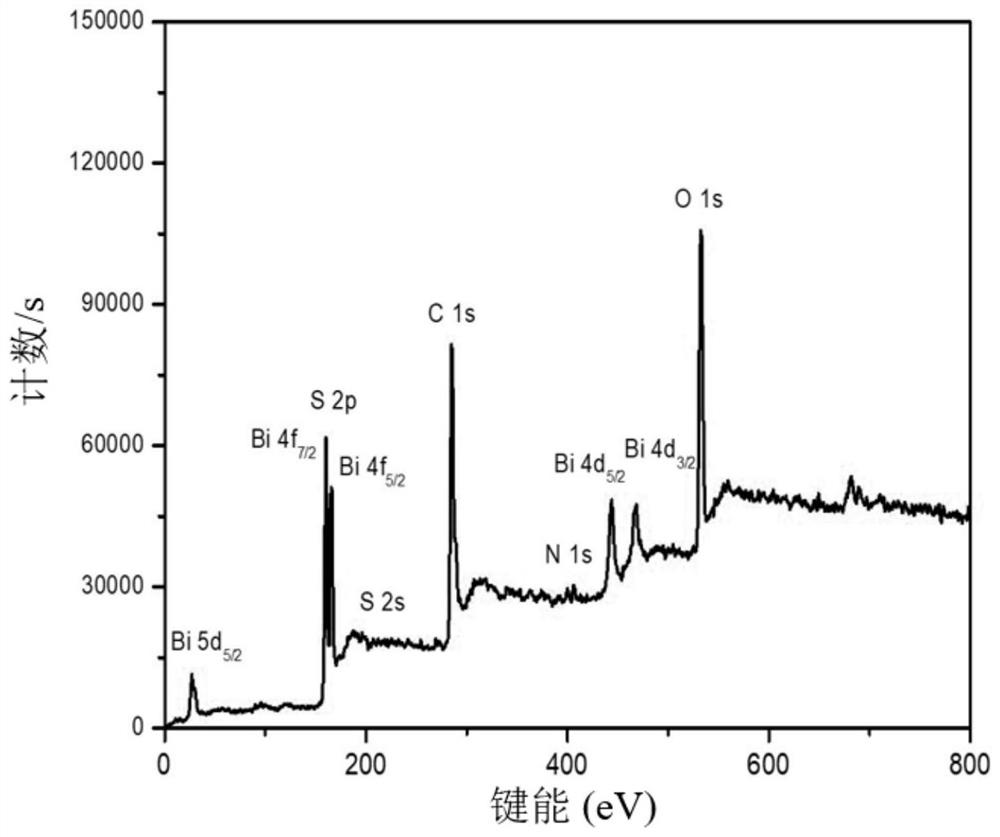

A kind of bismuth sulfide/bismuth oxide composite catalyst supported by three-dimensional porous carbon and its preparation method and application

A composite catalyst, three-dimensional porous technology, applied in the direction of electrolytic components, electrodes, electrolytic organic production, etc., can solve the problems of unfavorable environmental protection, poor conductivity, poor effect, etc., achieve good conductivity, improve conductivity, and improve catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step (1): Weigh 500 mg of powdered carrageenan, put it into a tube furnace for calcination, use nitrogen as the protective gas, calcine at a temperature of 600°C, and heat up at a rate of 5°C·min -1 , holding time is 2h;

[0041] Measure 40mL of ultrapure water and 5mL of concentrated sulfuric acid with a mass fraction of 98%, pour the concentrated sulfuric acid into ultrapure water for dilution, and obtain a concentration of 2mol L -1 dilute sulfuric acid; put the calcined carrageenan into a mortar and grind until uniform, put it into the above dilute sulfuric acid solution for pickling treatment, stir magnetically for 24 hours, filter the mixed solution after pickling, and use ultrapure water Washing is carried out, and the precipitate after washing is put into a vacuum drying oven, and the temperature is maintained at 60° C., and S-doped porous carbon nanosheets are obtained after drying;

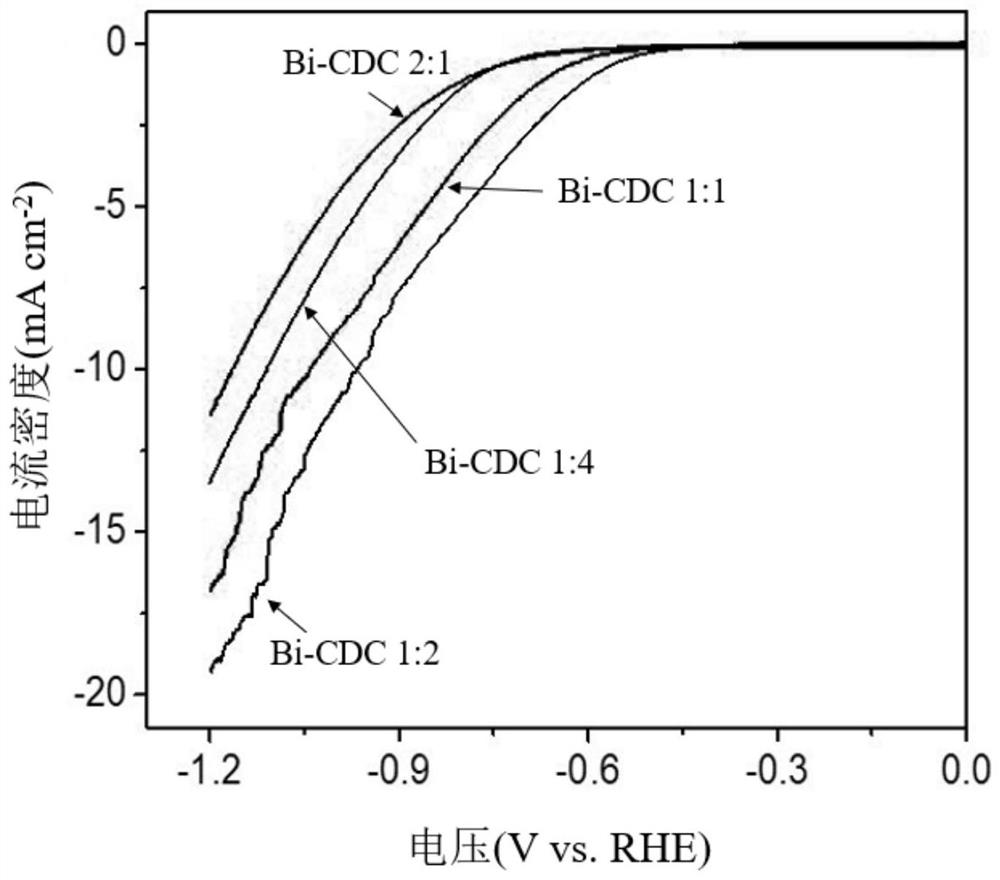

[0042] Step (2): Weigh 40 mg of the porous carbon nanosheets of step (1) and...

Embodiment 2

[0056] According to the preparation process of Example 1, the mass ratio of bismuth nitrate pentahydrate and porous carbon nanosheets is 1:2 in step (2), and the roasting temperature of carrageenan in step (1) is replaced by 500 ° C, 700 ° C, to obtain Composite catalyst Bi-CDC 500 1:2 and Bi-CDC 500 1:2.

[0057] According to the preparation process of Application Example 1, the composite catalyst prepared in Example 2 is used as cathode material, and the HCOOH Faradaic efficiency of the two catalysts at different voltages is as follows: Figure 7 shown. Bi-CDC 500 1:2 electrocatalytic CO 2 The highest Faradaic efficiency of reduction to HCOOH is about 90%, Bi-CDC 700 1:2 electrocatalytic CO 2 The highest faradaic efficiency of reduction to HCOOH is about 89%, which is lower than that of Bi-CDC 600 1:2 catalyst, indicating that the catalyst prepared by calcination temperature of 600℃ has the best performance.

Embodiment 3

[0059] According to the preparation process of Example 1, in step (2), the mass ratio of bismuth nitrate pentahydrate to porous carbon nanosheets is 1:2, and the hydrothermal reaction temperature in step (2) is replaced by 160°C and 200°C to obtain a composite Catalyst Bi-CDC 1:2 160 and Bi-CDC 1:2 200.

[0060] According to the preparation process of Application Example 1, the composite catalyst prepared in Example 2 is used as cathode material, and the HCOOH Faradaic efficiency of the two catalysts at different voltages is as follows: Figure 8 shown. Bi-CDC 1:2 160 electrocatalytic CO 2 The highest faradaic efficiency of reduction to HCOOH is about 85%, Bi-CDC 1:2 200 electrocatalytic CO 2 The highest Faradaic efficiency for reduction to HCOOH is about 45%. Compared with the Bi-CDC 600 1:2 catalyst, the performance has decreased, and the performance of the catalyst at 200 ° C has dropped significantly, indicating that the performance of the catalyst prepared by selecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com