Natural plant cat litter and production process

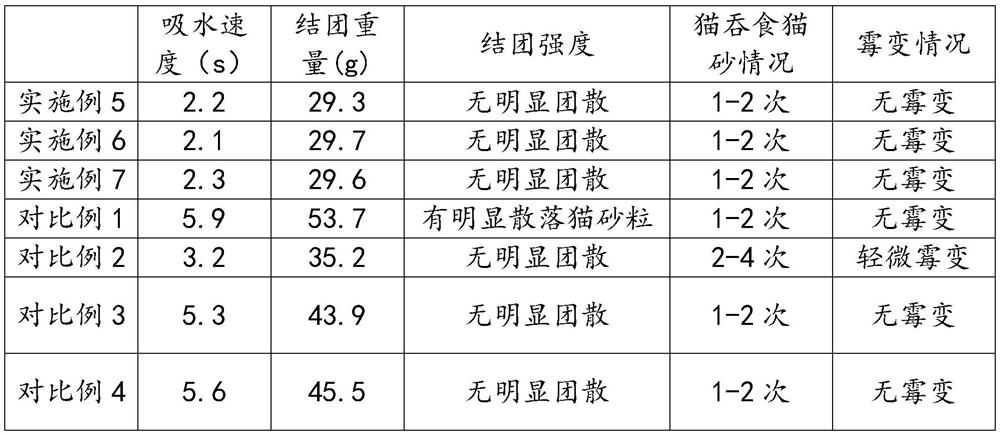

A technology of natural plants and cat litter, applied in plant growth regulators, botanical equipment and methods, biocides, etc., can solve the problems of low agglomeration of cat litter, susceptibility to moisture and mildew, etc., and achieve good water absorption performance and excellent water absorption Performance, the effect of enhancing the strength of the adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Composite modified corn starch is made through the following steps:

[0036] Step S1. Add the mechanically activated cornstarch and deionized water into a four-necked flask equipped with a stirrer and a thermometer, and transfer the four-necked flask to a water bath, heat to 35°C, and stir for 20 minutes, then wash with NaOH The solution adjusted the pH of the reaction system to 8.5, slowly added [3-(trimethoxysilyl)propyl] succinic anhydride, added within 1.5h, continued the reaction for 3h, adjusted the pH of the solution to 6.5 with HCl solution, and then added ethanol Precipitate, centrifuge, take the precipitate, and wash it twice with 80% ethanol, take the precipitate, and dry it in vacuum at 30°C for 6h to obtain the intermediate product 1, wherein, cornstarch, deionized water, [3-(trimethoxysilyl)propane Base] the adding mass ratio of succinic anhydride is 13:100:3.7;

[0037] Step S2, add the intermediate product 1 and deionized water obtained in step S1 into ...

Embodiment 2

[0040] Composite modified corn starch is made through the following steps:

[0041] With reference to the preparation steps of Example 1,

[0042] In step S1, the addition mass ratio of cornstarch, deionized water, [3-(trimethoxysilyl) propyl] succinic anhydride is 15:100:5;

[0043] In step S2, the mass ratio of intermediate product 1, deionized water, and potassium permanganate is 15:100:0.0012;

[0044] In step S3, the mass ratio of intermediate product 2, deionized water, epichlorohydrin, sodium bisulfite solution of ammonium persulfate, mixed monomer of butyl acrylate and acrylic acid amide is 20:100:0.004:0.01: 1. The mass ratio of ammonium persulfate and sodium bisulfite in the sodium bisulfite solution of ammonium persulfate is 1:1, and the mass ratio of butyl acrylate and acrylic acid amide in the mixed monomer of butyl acrylate and acrylic acid amide is 5 :1.

Embodiment 3

[0046] Composite modified corn starch is made through the following steps:

[0047] With reference to the preparation steps of Example 1,

[0048] In step S1, the mass ratio of corn starch, deionized water, [3-(trimethoxysilyl) propyl] succinic anhydride added is 25:100:7.5;

[0049] In step S2, the mass ratio of intermediate product 1, deionized water, and potassium permanganate is 18:100:0.0015;

[0050] In step S3, the mass ratio of intermediate product 2, deionized water, epichlorohydrin, sodium bisulfite solution of ammonium persulfate, mixed monomer of butyl acrylate and acrylic acid amide is 43:100:0.005:0.012: 3.5, the mass ratio of ammonium persulfate and sodium bisulfite in the sodium bisulfite solution of ammonium persulfate is 1:1, and the mass ratio of butyl acrylate and acrylic acid amide in the mixed monomer of butyl acrylate and acrylic acid amide is 1 :5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com