A kind of preparation method and application of two-dimensional porous cd-mofs

An application method and reaction technology, applied in the field of environmental analysis, can solve the problems of low adsorption efficiency and achieve the effects of large adsorption capacity, high adsorption performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation method of two-dimensional porous Cd-MOFs material

[0034] Add 3.2g of pyromellitic anhydride (PMDA) and 5.32g of 5-aminoisophthalic acid into 30mL of glacial acetic acid solution respectively, mix the two and stir and heat the mixed solution at 120°C for 24h, and the obtained white precipitate distilled water and CHCl 3 Wash three times, and then dry in an oven at 80°C to obtain a light yellow solid powder, and make imide ligand H 4 BDCPPI; 0.025 mmol of H 4 BDCPPI, 0.07mmol of Cd(NO 3 ) 2 4H 2 The mixed solution of 0 and 3mL of DMF was placed in a 25mL reaction kettle, the temperature was programmed to rise to 115°C within 6h, and the constant temperature reaction was carried out at 115°C for 36h, and the temperature was programmed to cool down to room temperature within 72h, and the obtained light yellow solid was vacuum filtered, and then used DMF and water were washed and dried to make Cd-MOFs crystal material.

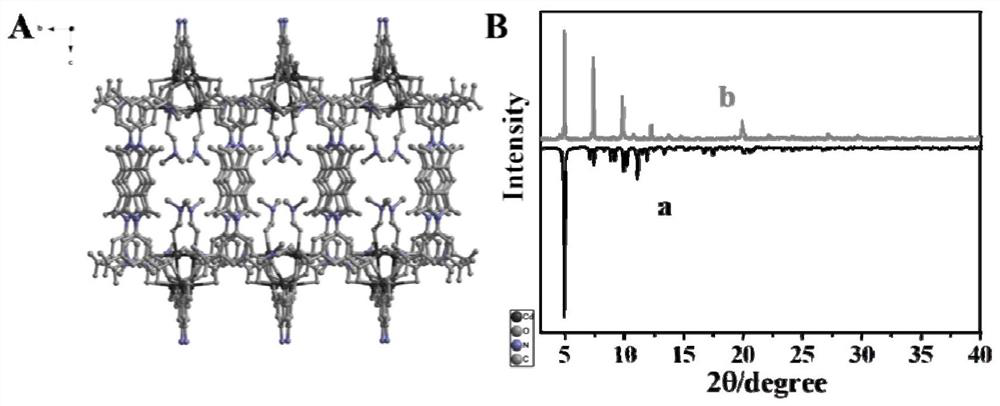

[0035] Using X-ray...

Embodiment 2

[0036] Example 2: Cd-MOFs to rare earth Tb 3+ Ratiometric Fluorescence Detection Applications

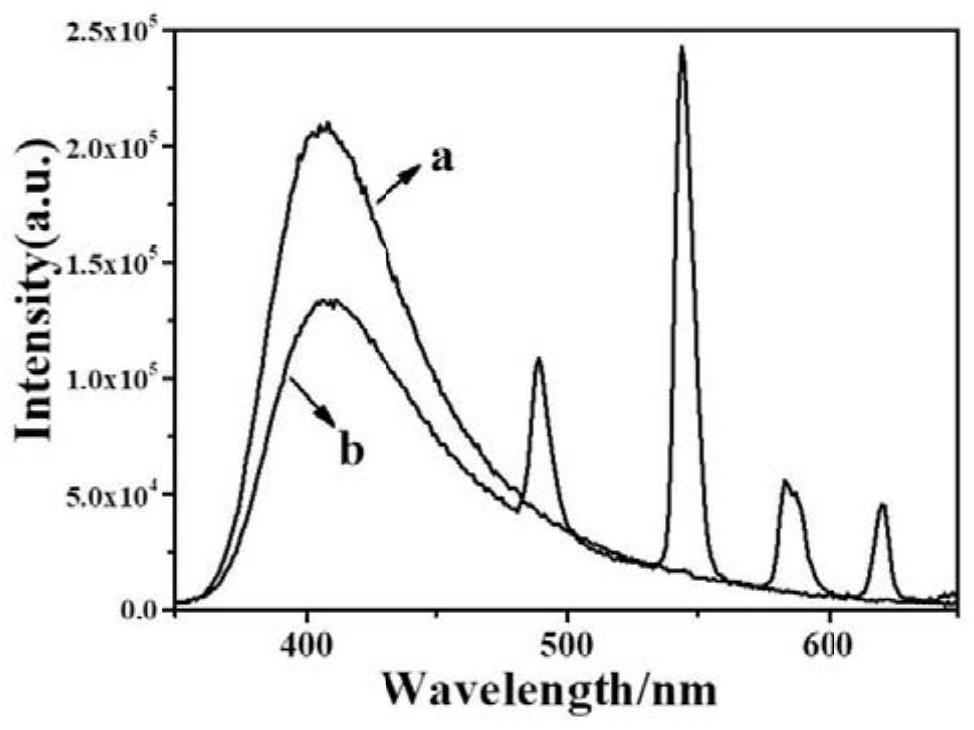

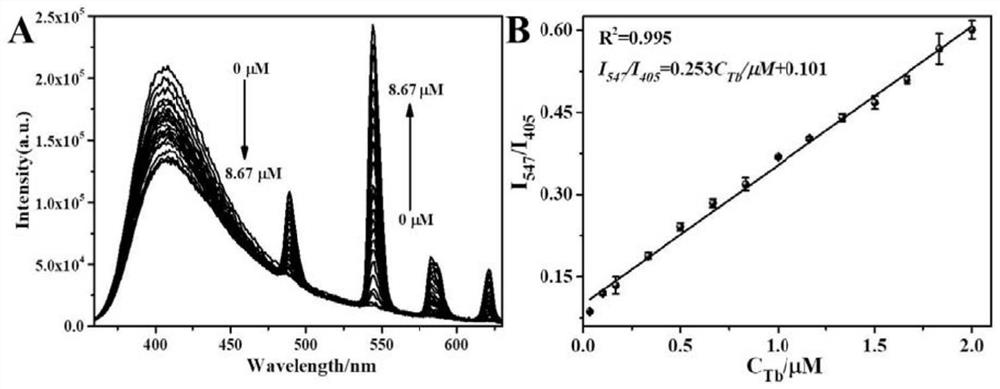

[0037] (1) Preparation and characterization of Cd-MOF fluorescent probe

[0038] Ultrasonic dispersion of 10 mg of Cd-MOFs material in 10 mL of ultrapure water was made into a 1 mg / mL suspension, and 200 μL of the Cd-MOFs suspension was diluted to 3 mL with ultrapure water to prepare a Cd-MOF fluorescent probe solution. Fluorescence spectroscopy of Cd-MOFs fluorescent probes and Tb 3+ The fluorescence characteristics before and after the reaction were characterized, and the results were as follows: figure 2 shown. Under the excitation wavelength of 264nm, the Cd-MOFs fluorescent probe has a strong fluorescent signal at 405nm (curve a); when adding Tb to the Cd-MOFs fluorescent probe 3+ After solution, the solution exhibits dual emission fluorescence signals, that is, simultaneously emitting Cd-MOFs and Tb 3+ Fluorescence signal of Cd-MOFs, where the intensity of the emission ...

Embodiment 3

[0045] Example 3: Enrichment application of Cd-MOFs to rare earth elements

[0046] (1) Cd-MOFs rare earth Tb 3+ The adsorption capacity measurement of

[0047] Under neutral conditions, 50 mg of Cd-MOFs was added to 50 mL containing different concentrations (0-800 ppm) of Tb 3+ In the solution, the suspension was stirred for 3h and filtered through a 0.22μm microporous membrane; the rare earth Tb in the filtrate was measured by inductively coupled plasma mass spectrometry 3+ Concentration, calculated Cd-MOFs to rare earth Tb 3+ of adsorption capacity. Cd-MOFs vs. Tb 3+ The adsorption capacity increases with Tb 3+ The concentration increases until the adsorption equilibrium state is reached ( Figure 5 A), and Qe / Ce and Ce have a good linear correlation ( Figure 5 B), Cd-MOFs on Tb 3+ The maximum adsorption capacity is 303mg / g.

[0048] (2) The enrichment rate of all rare earths by Cd-MOFs

[0049] In the presence of different rare earth ions, Cd-MOFs can also adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com