Method for improving hardness of zirconium and alloy thereof

A hardness and alloy technology, applied in the direction of testing material hardness, radiation pyrometry, metal material coating technology, etc., can solve the problems such as difficult to guarantee the service life, achieve good impact load, improve hardness and wear resistance, and excellent mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

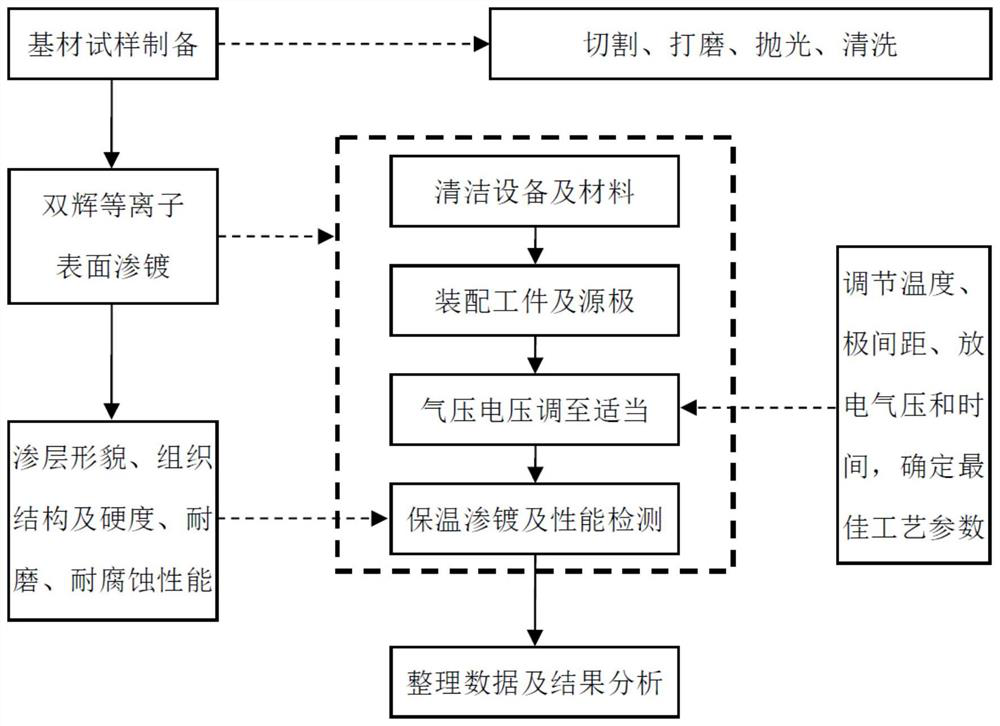

[0043] A method for improving the hardness of zirconium and its alloys, comprising the steps of:

[0044] Step 1: Clean equipment and experimental materials;

[0045] Step 2: Assemble the workpiece and the source, adjust the distance between the source and the workpiece, keep the bracket, insulation cover, etc. stable, and close the furnace body;

[0046] Step 3: After evacuating to about 1Pa, fill Ar gas to 30-50Pa, set the negative bias voltage of 400-500V on the cathode, and set the negative bias voltage of 800-1000V on the metal electrode to be infiltrated. Under the action of the bias voltage, the gas is ignited, A strong glow discharge is generated, and an unequal potential hollow cathode effect is generated between the cathode and the source, so that the workpiece is rapidly heated to a high temperature, so that the metal atoms to be infiltrated are sputtered out and deposited on the surface of the workpiece. Under the action of the atomic concentration gradient deposi...

Embodiment 2

[0058] A method for improving the hardness of zirconium and its alloys, comprising the steps of:

[0059] Step 1: Clean equipment and experimental materials;

[0060] Step 2: Assemble the workpiece and the source, adjust the distance between the source and the workpiece, keep the bracket, insulation cover, etc. stable, and close the furnace body;

[0061] Step 3: After evacuating to about 1Pa, fill Ar gas to 30-50Pa, set the negative bias voltage of 400-500V on the cathode, and set the negative bias voltage of 800-1000V on the metal electrode to be infiltrated. Under the action of the bias voltage, the gas is ignited, A strong glow discharge is generated, and an unequal potential hollow cathode effect is generated between the cathode and the source, so that the workpiece is rapidly heated to a high temperature, so that the metal atoms to be infiltrated are sputtered out and deposited on the surface of the workpiece. Under the action of the atomic concentration gradient deposi...

Embodiment 3

[0072] A method for improving the hardness of zirconium and its alloys, comprising the steps of:

[0073] Step 1: Clean equipment and experimental materials;

[0074] Step 2: Assemble the workpiece and the source, adjust the distance between the source and the workpiece, keep the bracket, insulation cover, etc. stable, and close the furnace body;

[0075] Step 3: After evacuating to about 1Pa, fill Ar gas to 30-50Pa, set the negative bias voltage of 400-500V on the cathode, and set the negative bias voltage of 800-1000V on the metal electrode to be infiltrated. Under the action of the bias voltage, the gas is ignited, A strong glow discharge is generated, and an unequal potential hollow cathode effect is generated between the cathode and the source, so that the workpiece is rapidly heated to a high temperature, so that the metal atoms to be infiltrated are sputtered out and deposited on the surface of the workpiece. Under the action of the atomic concentration gradient deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com