Modified lithium ferric manganese phosphate material, and preparation method and application thereof

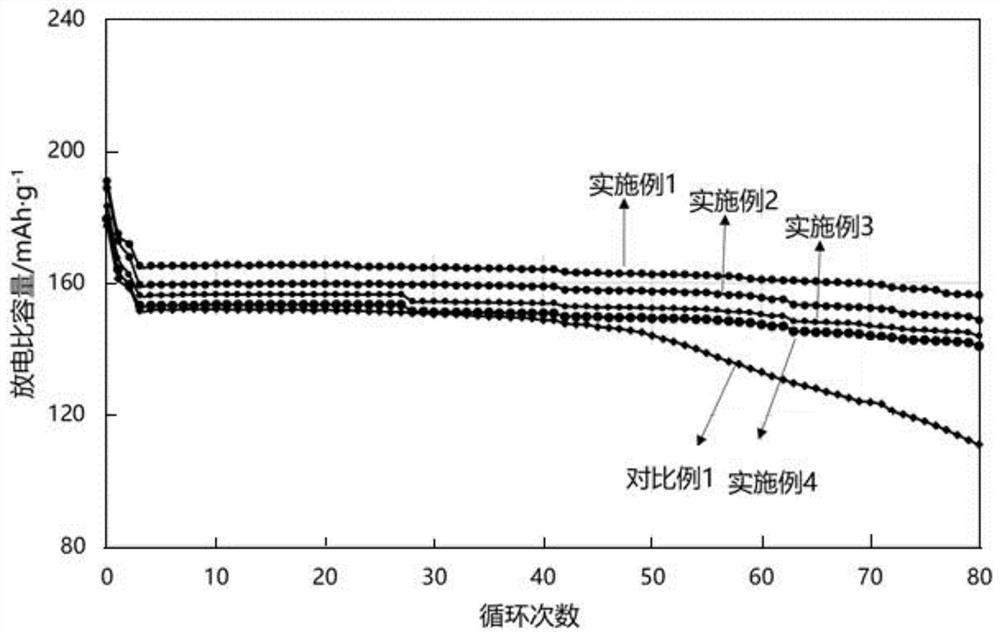

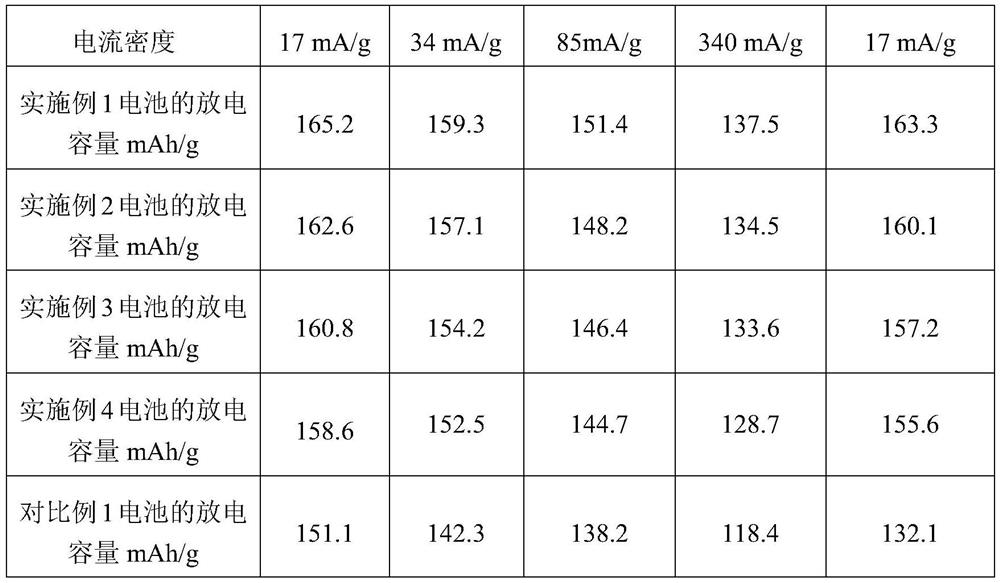

A modified technology of lithium iron manganese phosphate, applied in chemical instruments and methods, phosphorus compounds, active material electrodes, etc., can solve the problems of lithium ion battery cycle performance, poor rate performance, and low electronic conductivity and lithium ion diffusion rate , to achieve the effects of high charge and discharge efficiency and capacity, low charge transfer resistance, and better cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] According to another aspect of the present invention, the present invention also provides a method for preparing the above-mentioned modified lithium iron manganese phosphate material, comprising the following steps: mixing manganese source, phosphorus source, iron source, lithium source, magnesium source and water, An intermediate reaction liquid is formed; the intermediate reaction liquid is sequentially dried and pre-calcined to obtain a nuclear layer precursor; the nuclear layer precursor is mixed with a boron source and then calcined to obtain a modified lithium iron manganese phosphate material.

[0026] In the above preparation method, first utilize manganese source, phosphorus source, iron source, lithium source and magnesium source and water to mix, form intermediate reaction liquid, like this, can earlier magnesium source and iron manganese phosphate lithium main component be mixed, impel the magnesium source The dispersion uniformity is better, and during the ...

Embodiment 1

[0041] 1. Mn(CH 3 COO) 2 4H 2 O, NH 4 h 2 PO 4 , Fe(CH 3 COO) 2 、CH 3 COOLi·2H 2 O, Mg(OH) 2 Mix evenly at a molar ratio of 0.44:1:0.58:1.05:0.03, dissolve in 300mL deionized water, stir evenly with a stirring paddle, place it in a water bath at 65°C and stir for 6 hours to obtain an intermediate reaction solution.

[0042] 2. Dry the obtained intermediate reaction solution in a vacuum drying oven at 105°C for 24 hours, and then perform roller crushing and ultra-centrifugal grinding and crushing in turn, and then place it in a nitrogen protective atmosphere and heat it in a tube furnace at 400°C Intermediate calcining for 6 hours, with a heating rate of 2°C / min, to obtain the core layer precursor;

[0043] 3. Take the above 10g nuclear layer precursor, and carry out roller crushing and ultracentrifugal grinding and pulverizing treatment to it successively. The D50 of the nuclear layer precursor precursor is 8 μm, and mix it with 8.2g boric acid (boric acid is its pre...

Embodiment 2

[0046] The difference with Example 1 is:

[0047] Mn(CH 3 COO) 2 4H 2 O, NH 4 h 2 PO 4 , Fe(CH 3 COO) 2 、CH 3 COOLi·2H 2 O, Mg(OH) 2 The mixing ratio is 0.43:1:0.59:1.05:0.01, and the boric acid is 60% of the total weight of the precursor and the core layer precursor. During the pre-calcination process, the treatment temperature was 350°C and the treatment time was 8h; during the roasting treatment, the treatment temperature was 750°C and the treatment time was 10h. The obtained modified iron manganese phosphate lithium material, its iron manganese phosphate lithium core layer is Li(Fe 0.57 mn 0.43 ) 0.99 Mg 0.01 PO 4 , the cladding layer is a boron oxide layer.

[0048] Wherein, the particle size of the magnesium-doped lithium iron manganese phosphate core layer is 6 μm, and the average thickness of the boron-containing coating layer is 8 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com