Carbon nitride heterojunction photocatalyst and preparation method and application thereof

A technology of photocatalyst and carbon nitride, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of slow electron transfer rate, improve separation ability, improve dispersibility, improve absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

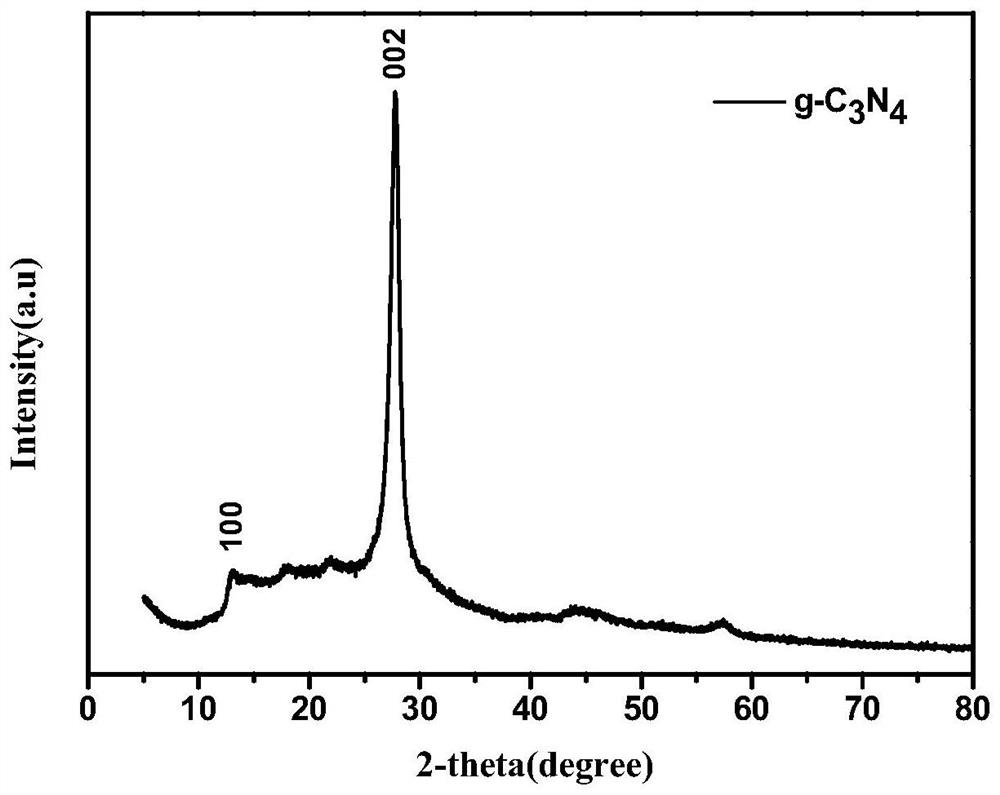

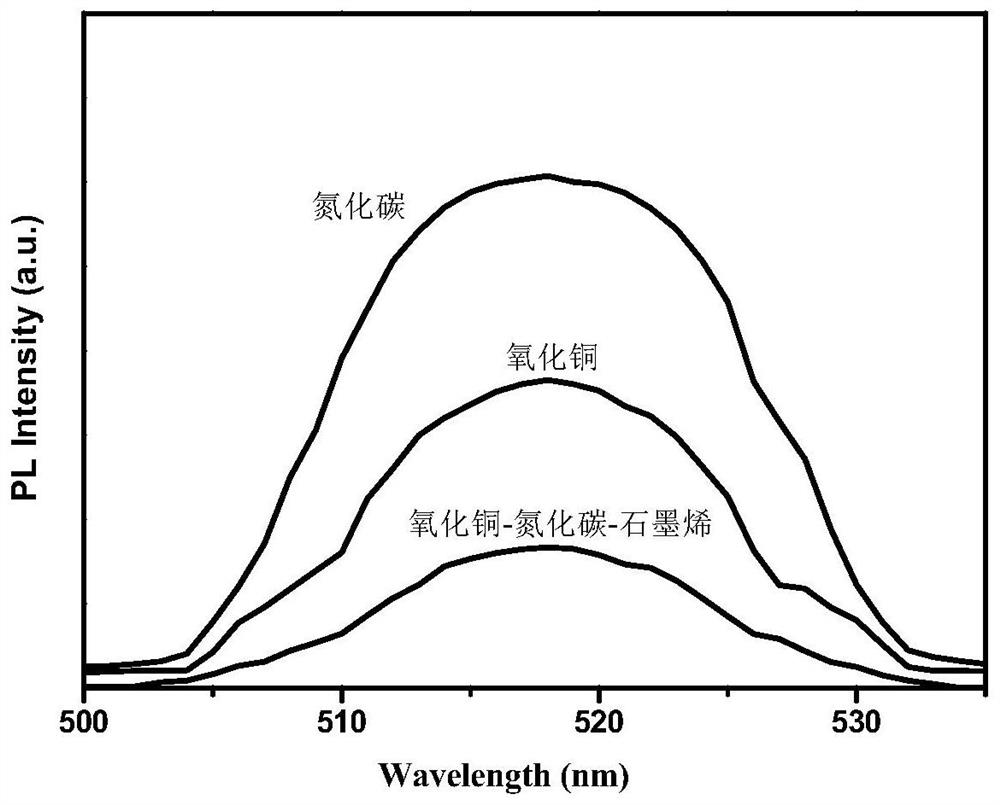

[0031] Melamine was placed in a crucible and heated to 550°C in a muffle furnace, and kept at a constant temperature for 4 hours; after cooling to room temperature, it was ultrasonically treated in 0.1M nitric acid solution for 8 hours, finally washed to neutral with deionized water, and dried at 60°C. Depend on figure 1 It can be seen from XRD that after melamine is decomposed by high temperature, carbon nitride is obtained after drying. Graphene oxide was dissolved in distilled water, sonicated for 30 minutes, and then the pH was adjusted to 9 with NaOH to obtain a graphene oxide solution. Add copper oxide to the graphene oxide solution, sonicate for 2 hours, add carbon nitride to the above-mentioned graphene oxide solution containing metal oxides, make the mass ratio 1:1:0.8, stir for 12 hours, and the final mixture is in the reaction kettle React at 180°C for 12h. After that, it was freeze-dried at -20°C for 24 hours to obtain a carbon nitride heterojunction catalyst. T...

Embodiment 2

[0036] Melamine is placed in a crucible and heated to 550°C in a muffle furnace, and kept at a constant temperature for 4 hours; after cooling to room temperature, it is ultrasonically treated in 0.1M nitric acid solution for 8 hours, finally washed with deionized water until neutral, and dried at 60°C to obtain carbon nitride . Graphene oxide was dissolved into distilled water, sonicated for 30 min, and then the pH was adjusted to 9 with NaOH. Zinc oxide was added to the obtained graphene oxide solution and ultrasonicated for 3 hours. Carbon nitride was added to the graphene oxide solution containing metal oxides so that the mass ratio was 1:1:0.4, stirred for 12 hours, and the final mixture was reacted at 180° C. for 22 hours in a reactor. After that, it was freeze-dried at -20°C for 24 hours to obtain a carbon nitride heterojunction catalyst. The catalyst was then dissolved with a mixture of 5% Nafion solution and 95% ethanol aqueous solution at a volume ratio of 1:5. Ca...

Embodiment 3

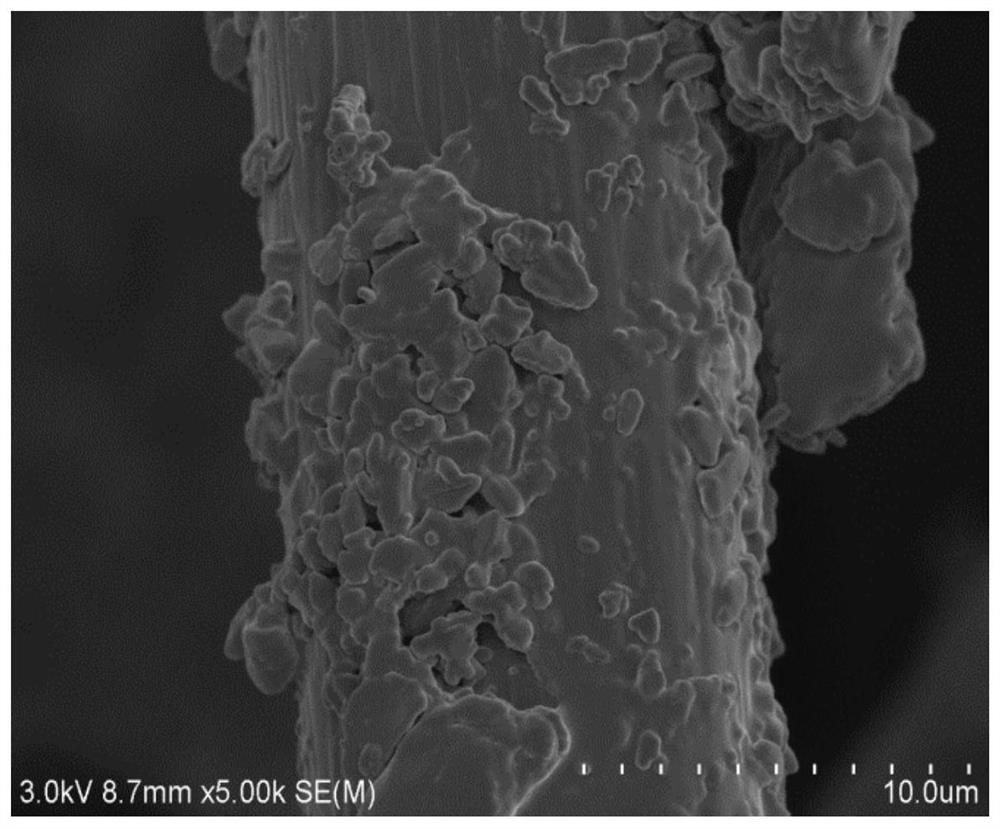

[0039] Melamine is placed in a crucible and heated to 550°C in a muffle furnace, and kept at a constant temperature for 4 hours; after cooling to room temperature, it is ultrasonically treated in 0.1M nitric acid solution for 8 hours, finally washed with deionized water until neutral, and dried at 60°C to obtain carbon nitride . Graphene oxide was dissolved into distilled water, sonicated for 30 min, and then the pH was adjusted to 9 with NaOH. Add copper oxide to the obtained graphene oxide solution, and sonicate for 4 hours. Carbon nitride was added to the graphene oxide solution containing metal oxides so that the mass ratio was 1:1:0.2, stirred for 12 hours, and the final mixture was reacted in a reactor at 160° C. for 20 hours. After that, it was freeze-dried at -20°C for 24 hours to obtain a carbon nitride heterojunction catalyst. The catalyst was then dissolved with a mixture of 5% Nafion solution and 95% ethanol aqueous solution with a volume ratio of 1:10. Carbon f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com