Flame-retardant nylon material for battery pack shell and preparation method of flame-retardant nylon material

A technology for flame-retardant nylon and battery packs, applied in the field of polymer materials, can solve problems such as flame-retardant performance to be improved, battery module fire, safety accidents, etc., to achieve enhanced anti-corrosion effect, increased carbon layer density, and good high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

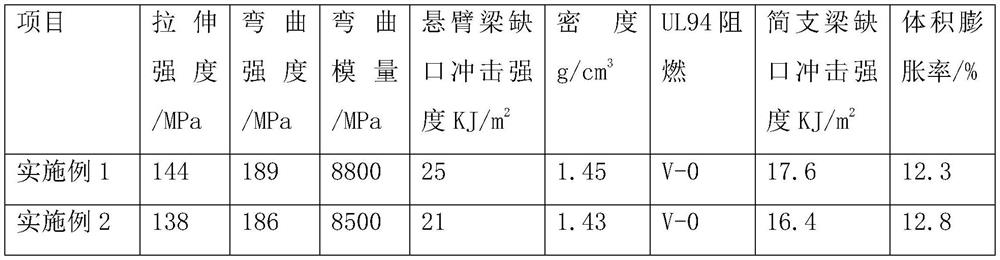

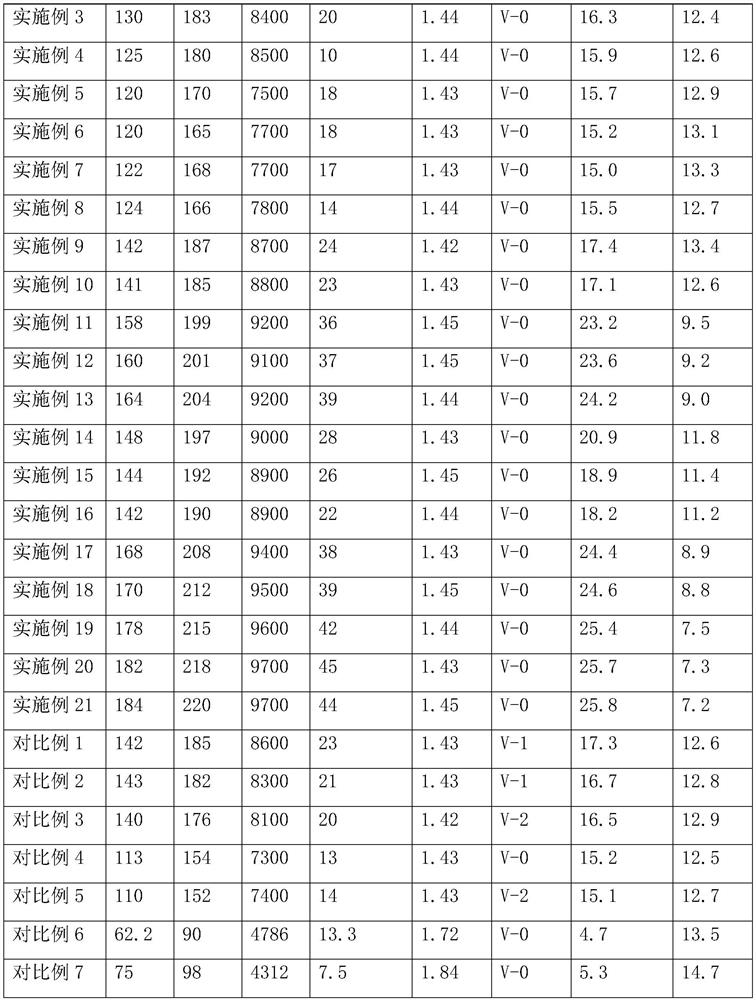

Examples

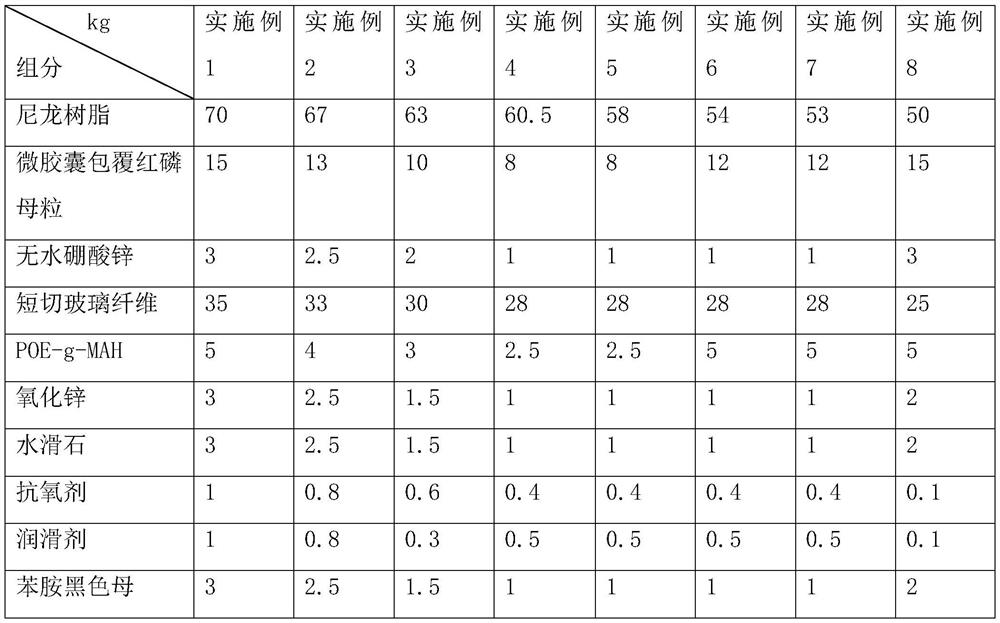

preparation example 1-8

[0038] In Preparation Example 1-8, cerium dioxide was selected from Bohuas Nano Technology (Ningbo) Co., Ltd.; poly-4-methyl-1-pentene was selected from Dongguan Suyun Plastic Co., Ltd.; expandable graphite was selected from Hongyue, Gongyi City Refractory Co., Ltd., the model is HY-SM; maleic anhydride grafted polyethylene is selected from Shenzhen Haian Plastic Chemical Co., Ltd., the model is PE1040.

preparation example 1

[0039] Preparation Example 1: (1) Mix 1kg red phosphorus with 1.5kg water, grind at a speed of 300r / min for 3h, dry in vacuum at 80°C for 3h, mix with 2kg ammonia water, 3.5kg tetraethyl orthosilicate, 2kg ethanol, 3kg Cerium dioxide is mixed, stirred for 5 hours, centrifuged, and vacuum-dried at 60°C for 10 hours. The purity of ceria is greater than 99.99%, and the density is 7.13g / cm 3 , the specific surface area is 90.86m 2 / g; (2) 3kg poly-4-methyl-1-pentene and 10kg step (1) gain are mixed, extrude, granulate, make microcapsules and coat red phosphorus masterbatch, and the temperature of a district is 175 ℃, the temperature in the second zone is 215 ℃, the temperature in the third zone is 235 ℃, the temperature in the fourth zone is 240 ℃, and the temperature in the fifth zone is 245 ℃.

preparation example 2

[0040] Preparation Example 2: (1) Mix 1.3kg of red phosphorus with 1.8kg of water, grind at a speed of 300r / min for 3h, dry in vacuum at 80°C for 3h, mix with 2.5kg of ammonia water, 4.5kg of ethyl orthosilicate, 2.3kg of Mix ethanol and 3.5kg ceria, stir for 5.5h, centrifuge, and vacuum dry at 60°C for 10h. The purity of ceria is greater than 99.99%, and the density is 7.13g / cm 3 , the specific surface area is 90.86m 2 / g;

[0041] (2) 4kg poly-4-methyl-1-pentene and 15kg step (1) gain are mixed, extrude, granulate, make microcapsule coating red phosphorus masterbatch, the temperature of one district is 175 ℃, two The temperature in the zone is 215°C, the temperature in the third zone is 235°C, the temperature in the fourth zone is 240°C, and the temperature in the fifth zone is 245°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com