Method for electrocatalytic reduction of CO2 by using nitrogen-doped carbon nanotubes with different curvatures

A technology of nitrogen-doped carbon and electrocatalysis, which is applied in nanotechnology, chemical instruments and methods, nanotechnology, etc. for materials and surface science, and can solve the problems of unexplored substrate material tube diameter curvature, catalytic performance, electronic properties and catalytic properties. issues of nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An electrocatalytic reduction of CO using nitrogen-doped carbon nanotubes with different curvatures 2 methods, including:

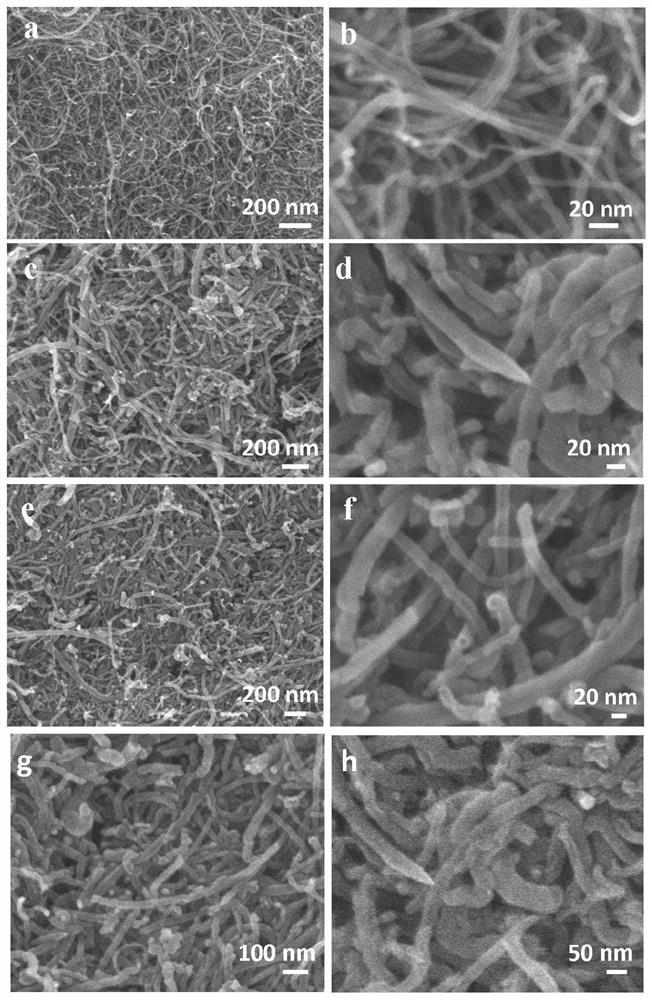

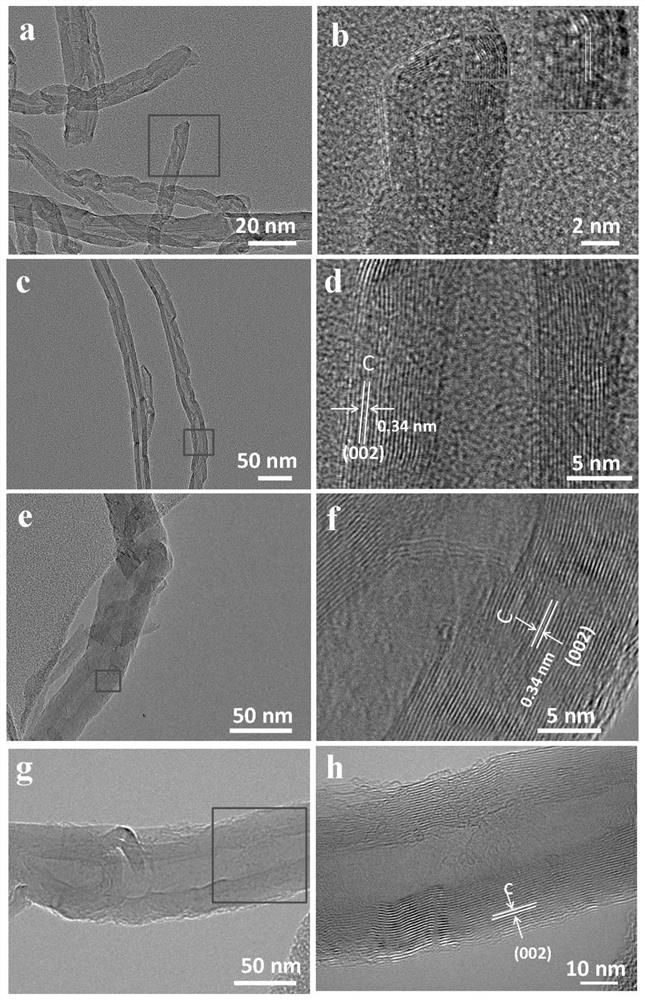

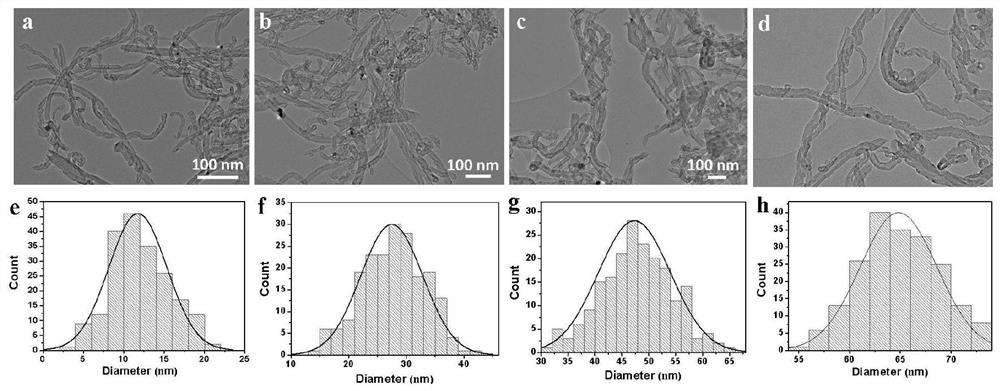

[0033] Step 1: Pretreating the multi-walled carbon nanotubes (CNTs): soaking in deionized water treatment, ultrasonic treatment for 20-30 minutes, removing impurities on the surface and drying; the diameter of the CNTs is 27±4nm;

[0034] Step 2: Preparation of nitrogen-doped carbon nanotubes (NCNTs): put the CNTs treated in step 1 into a tube furnace at a heating rate of 3°C / min, pretreatment at 500°C for 1h; then at the same heating rate , heated up to 1000°C, and treated with ammonia gas for 2 hours to obtain NCNT, denoted as M-NCNT-1000;

[0035] Step 3: Preparation of electrode material: Sonicate 5 mg of M-NCNT-1000 prepared in step 2 with 100 μL of water, 400 μL of ethanol and 75 μL of nafion aqueous solution for 30 minutes to obtain a dispersion of M-NCNT-1000, and then take it out with a pipette 30μL of M-NCNT-1000 dispersion solution, dr...

Embodiment 2

[0039] In this example, the diameter of the CNT is 46±5nm, and the prepared NCNT is recorded as L-NCNT-1000; other conditions are the same as in Example 1.

Embodiment 3

[0041] In this example, the diameter of the CNT is 65±5nm, and the prepared NCNT is recorded as L2-NCNT-1000; other conditions are the same as in Example 1.

[0042] In order to further illustrate the beneficial effects of the present invention, comparative examples are provided as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com