Method for rapidly measuring content of chromium in copper or copper alloy

A measurement method and rapid measurement technology, which are applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of high test cost, large matrix interference, long test period, etc., and can eliminate the background intensity of spectral lines. The effect of eliminating the influence of spectral line intensity, the effect of high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

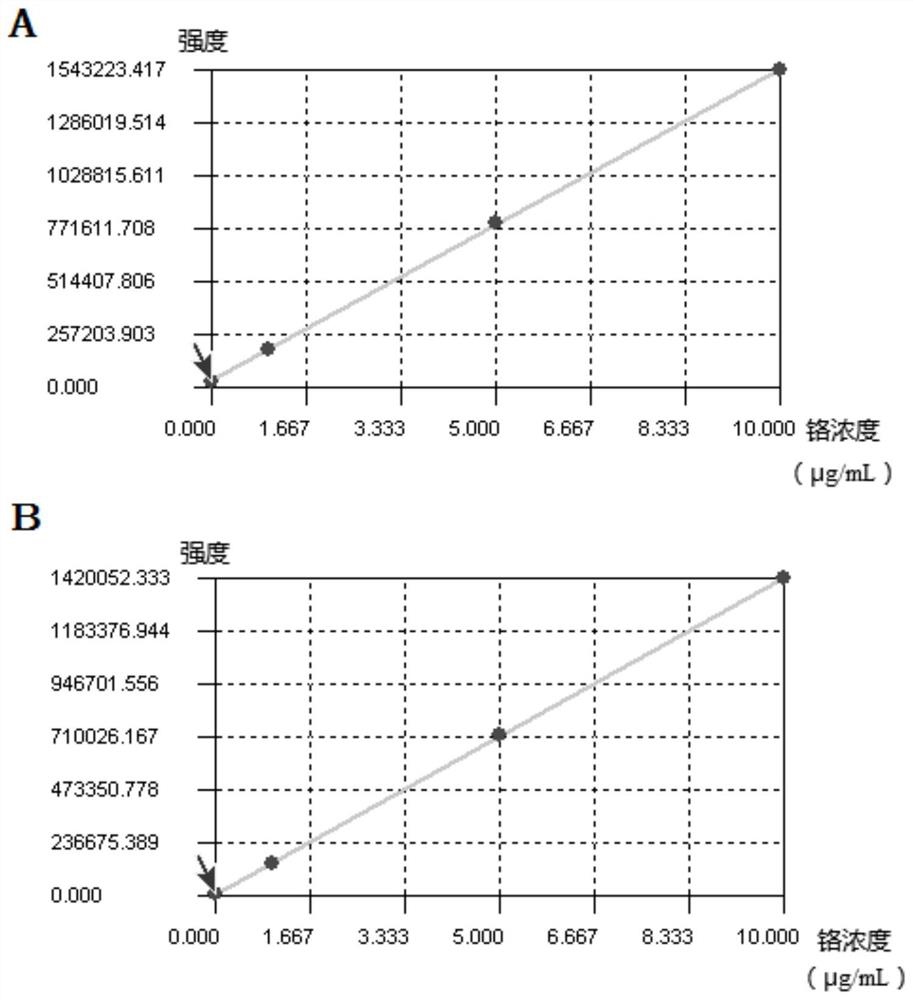

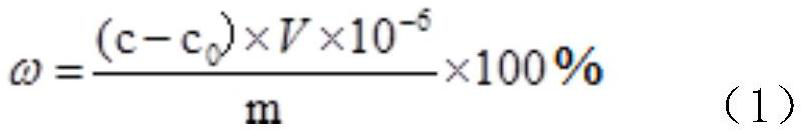

Image

Examples

Embodiment 1

[0067] This embodiment provides a quick determination method of chromium content in copper or copper alloy, taking the detection of chromium element content in copper-zinc alloy as an example, including the following steps:

[0068] Step 1: Collect the sample, and use a lathe, drill press or scissors to make the copper or copper alloy sample into a chip-like sample with a thickness not greater than 1mm, and ensure that the sample is free from oxidation, pollution and other impurities. The smaller the particle size of the sample, the larger the contact specific surface area with the acid during the dissolution process, and the better the detection effect. If the thickness of the sample is greater than 1 mm, it may cause incomplete dissolution of chromium in the sample, and the content of chromium in the sample cannot be accurately tested.

[0069] Step 2, prepare reagents:

[0070] Hydrochloric acid (ρ=1.19g / mL), superior grade;

[0071] Nitric acid (ρ=1.42g / mL), superior gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com